Table 1 – airflow vs. velocity wing™ signal, Electric analog connections, Electronic ddc controls – Anemostat EST User Manual

Page 20: Non-flow thru / dead head), Factory-mounted, controls by others)

20

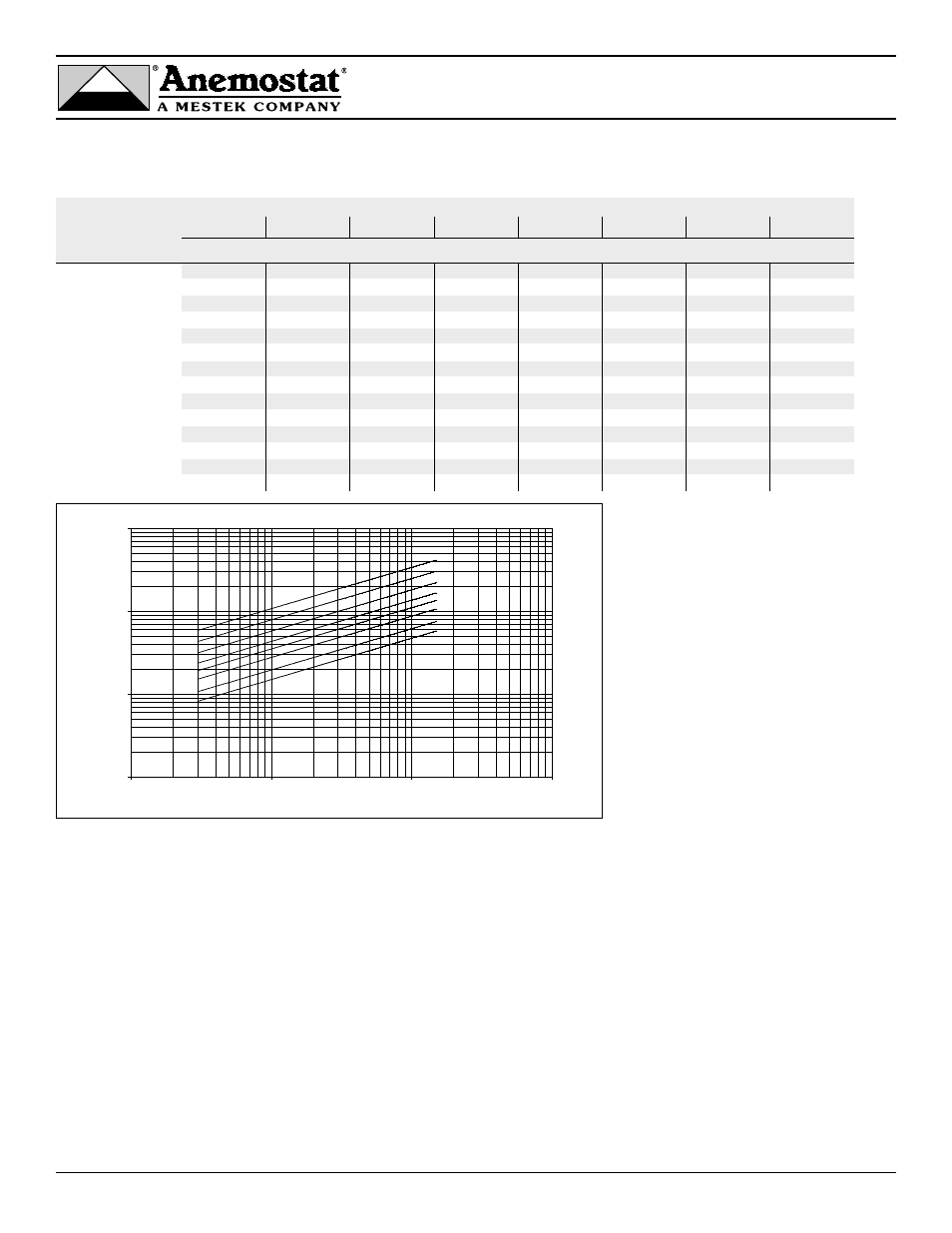

Table 1 – Airflow vs. Velocity Wing™ Signal

(Non-Flow Thru / Dead Head)

Inlet Size

6

7

8

9

10

12

14

16

Sensor dP

CFM

0.03

81

106

150

190

234

312

428

583

0.04

94

122

173

220

271

360

494

673

0.06

115

150

212

269

331

441

605

824

0.1

148

194

274

347

428

570

781

1064

0.2

210

274

388

491

605

806

1104

1505

0.3

257

335

475

601

741

987

1352

1844

0.4

297

387

548

694

856

1140

1562

2129

0.5

332

433

613

776

957

1274

1746

2380

0.6

363

474

672

851

1048

1396

1912

2607

0.7

392

512

725

919

1132

1508

2066

2816

0.8

419

547

775

982

1210

1612

2208

3011

0.9

445

581

823

1042

1284

1710

2342

3193

1 (K-Factor)

469

612

867

1098

1353

1802

2469

3366

1.5

574

750

1062

1345

1657

2207

3024

4122

Electric Analog Connections

Electronic controls are typically factory wired for single point power voltage supply with fan relay and 24VAC power

(from a step-down transformer) as part of the fan circuit or electric heater circuit.

1. The remote mounted thermostat is connected to the appropriate components located in the control box. See the

control wiring diagram affixed to the inside of cover.

2. When hot water reheat is used, the relay in the control box must be wired to the water valve actuator.

Electronic DDC Controls

(Factory-mounted, controls by others)

IMPORTANT All RS485 communication networks must be installed using twisted, shielded pair wiring. Each twisted

pair must be individually shielded. If using unshielded wiring, cables must be placed in solid metal conduit alone,

without DC switching or AC lines. Failure to use these types of connectors may result in various system

communication problems such as excessive network retries, noise susceptibility, and loss of communication.

If proper wiring is not used, the site may not meet FCC class A regulations for RFI emissions; thereby forcing the

installer or user to make the necessary wiring changes at a later date.

Velocity Wing Calibration

10

100

1000

10000

0.01

0.1

1

10

Sensor dP

CFM

6

7

8

9

10

12

14

16

TM

50

500

Unit

Size

1.5

2000

5000

200

20