Material qualifications – GEARENCH SCT2036 PETOL SURGRIP Casing Tong User Manual

Page 15

13

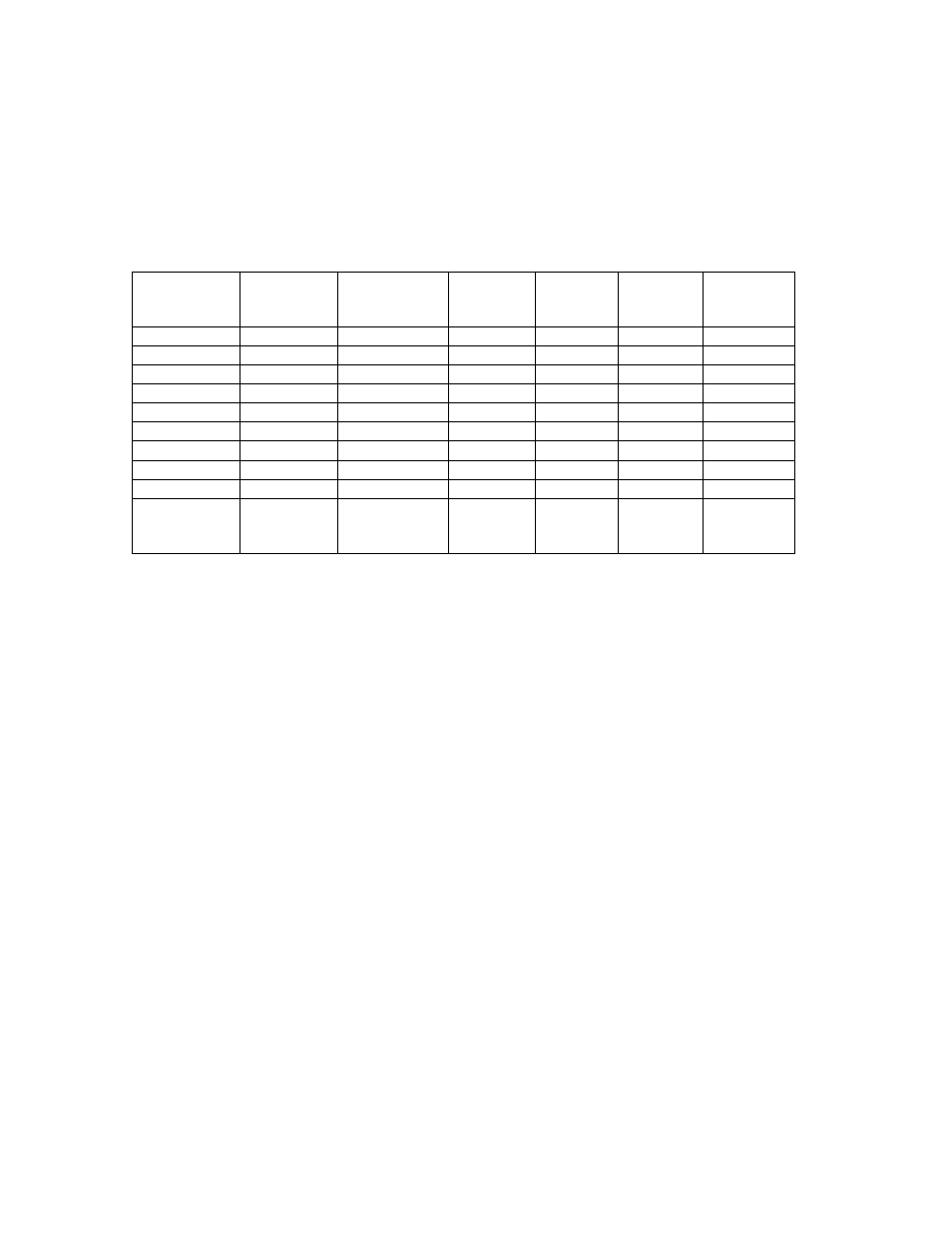

Material Qualifications

The following table is a list of the materials and grades used in the manufacture of the

SCT2036 SURGRIP™ Casing Tong.

Note: Yield and tensile strengths are post heat treat. Parts are heat treated after machining.

Part

Number

Description

Material

Yield

Strength

(min)

Tensile

Strength

(min)

Charpy

Impact

(min)

Reduction

of Area

(min)

SCTH2036

Handle

AISI 4318

110 ksi

120 ksi

31.0 (a)

25 %

SCTJ2036

Jaw

AISI 4318

116 ksi

125 ksi

31.0 (a)

25 %

HP403

Pin

AISI 4140

165 ksi

180 ksi

11.0 (b)

25 %

HI09D

Insert

AISI M2

N/A

N/A

N/A

N/A

SCTY2036-1

Yoke plate

AISI 4340

125 ksi

135 ksi

31.0 (a)

25 %

SCTY2036-2

Yoke grip

AISI 1018

N/A

N/A

N/A

N/A

HP387

Pin

AISI 4140

165 ksi

180 ksi

11.0 (b)

25 %

HP388

Pin

AISI 4140

165 ksi

180 ksi

11.0 (b)

25 %

HH18 (c)

Hanger

AISI 1018

N/A

N/A

N/A

N/A

SCTB2036

Belt

Aramid-

Polyurethane

Composite

N/A

N/A

N/A

N/A

(a) Charpy impact, when applicable, to be tested at -4°F, with a minimum average value of 31.0 ft-lb, and,

with no indication below 24 ft-lb.

(b) Charpy impact, when applicable, to be tested at -4°F, with a minimum average value of 11.0 ft-lb, and,

with no indication below 8.5 ft-lb.

(c) This item is not a primary load carrying component.