Elmo Rietschle G-BH9 User Manual

Page 26

Servicing

610.44434.40.000

26 / 32

© Gardner Denver Deutschland GmbH

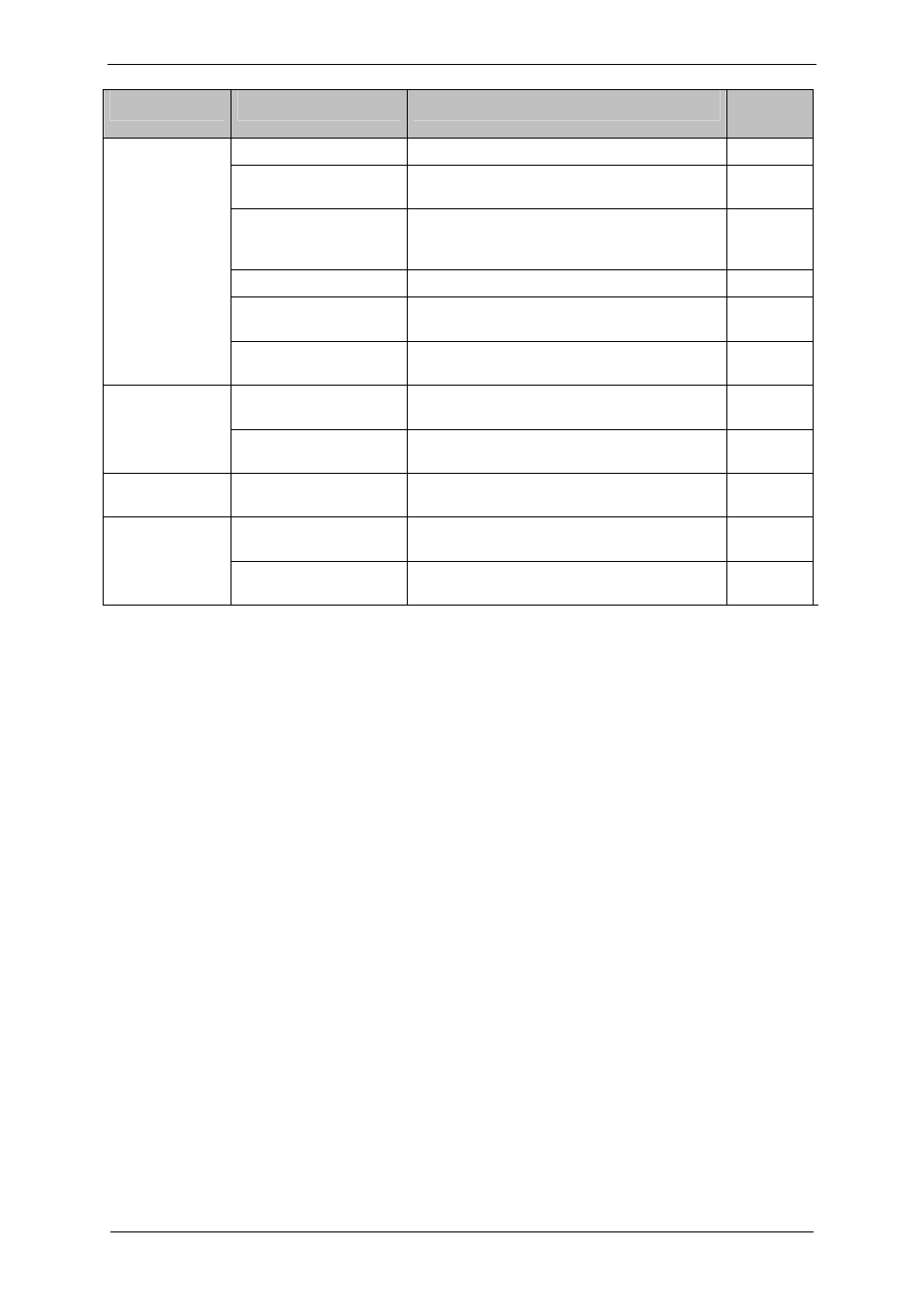

Fault

Cause

Remedy

Carried

out by

Leak in system.

Seal leak in the system.

Operator

Wrong direction of

rotation.

Reverse direction of rotation by interchanging

two connecting leads.

Electrician

Incorrect frequency (on

pump-motor units with

frequency converter).

Correct frequency.

Electrician

Shaft seal defective.

Replace shaft seal.

Service*

)

Different density of

pumped gas.

Take conversion of pressure values into

account. Inquire with Service Department.

Service

Pump-motor unit

does not

generate any or

generates

insufficient

pressure

difference.

Change in blade profile

due to soiling.

Clean impeller, check for wear and replace if

necessary.

Service*

)

Flow speed too high.

Clean pipes. Use pipe with larger cross-

section if necessary.

Operator

Abnormal flow

noises.

Muffler soiled.

Clean muffler inserts, check condition and

replace if necessary.

Service*

)

Abnormal

running noise.

Ball bearing lacking

grease or defective.

Regrease or replace ball bearing.

Service*

)

Seals on muffler

defective.

Check muffler seals and replace if necessary.

Service*

)

Compressor

leaky.

Seals in motor area

defective.

Check motor seals and replace if necessary.

Service

*

)

Only when the maintenance manual is at hand: rectification by the operator.