Elmo Rietschle G-BH1 Extra instruction manual User Manual

Page 6

reg. 9 Maintenance

610.44479.40.000

6 / 12

© Gardner Denver Deutschland GmbH

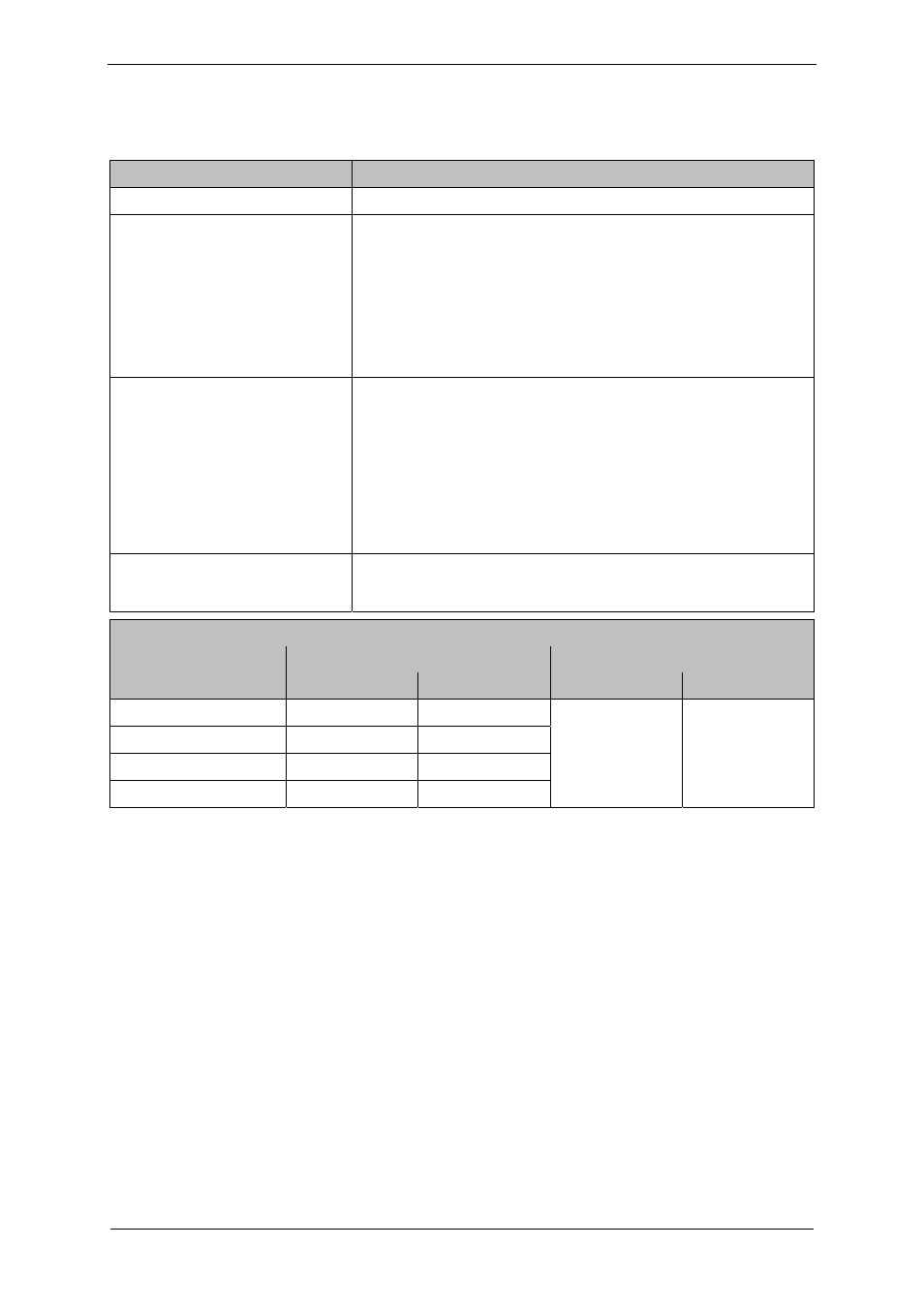

reg. 9.1 Repairs / Troubleshooting

Under normal operational conditions (max. +40ºC gas intake and ambient air temperature, permissible

total pressure difference) the following apply:

Interval

Maintenance procedure

weekly

Remove dust deposits from unit.

weekly

(only biogas uses)

Inspect unit for leaks

One of the following procedures will suffice for the inspection:

Check the unit for smears, ice formation, odours and noises

resulting from leakage.

Inspect the unit using a mobile leak detection device or portable

gas sensor equipment.

Continuous or periodical monitoring of the atmosphere using fitted

automatic measuring devices with warning system.

Every 2 years, or in accordance

with Lubrication service life/ re-

greasing interval on page 6.

Replace enclosed ball bearings units.

AND

Re-grease open ball bearings.

Clean used grease and dirt from ball bearings and adjacent grease

cups.

Fill half the space in the bearing casement and 65% of the

adjacent grease cups with grease.

Grease type: UNIREX N3, or in accordance with DIN 51825-K3N

Every 2 years, or in accordance

with Lubrication service life/ re-

greasing interval on page 6.

Replace shaft sealing rings.

Lubrication service life/ re-greasing interval

Type

Vacuum operation at

Compressor operation at

50 Hz

60 Hz

50 Hz

60 Hz

2BH151.-7H.4

15.000 14.000

2BH161.-7H.5

16.000 14.500

2BH190.-7..3

13.000 12.000

all other 2BH1….

18.000 18.000

18.000 18.000