Elmo Rietschle C-VLR 250/300/400/500 User Manual

Page 25

25

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

|

Maintenance and repair

s

4

q

k

m

n

2

m

s

5

q

n

1

v

k

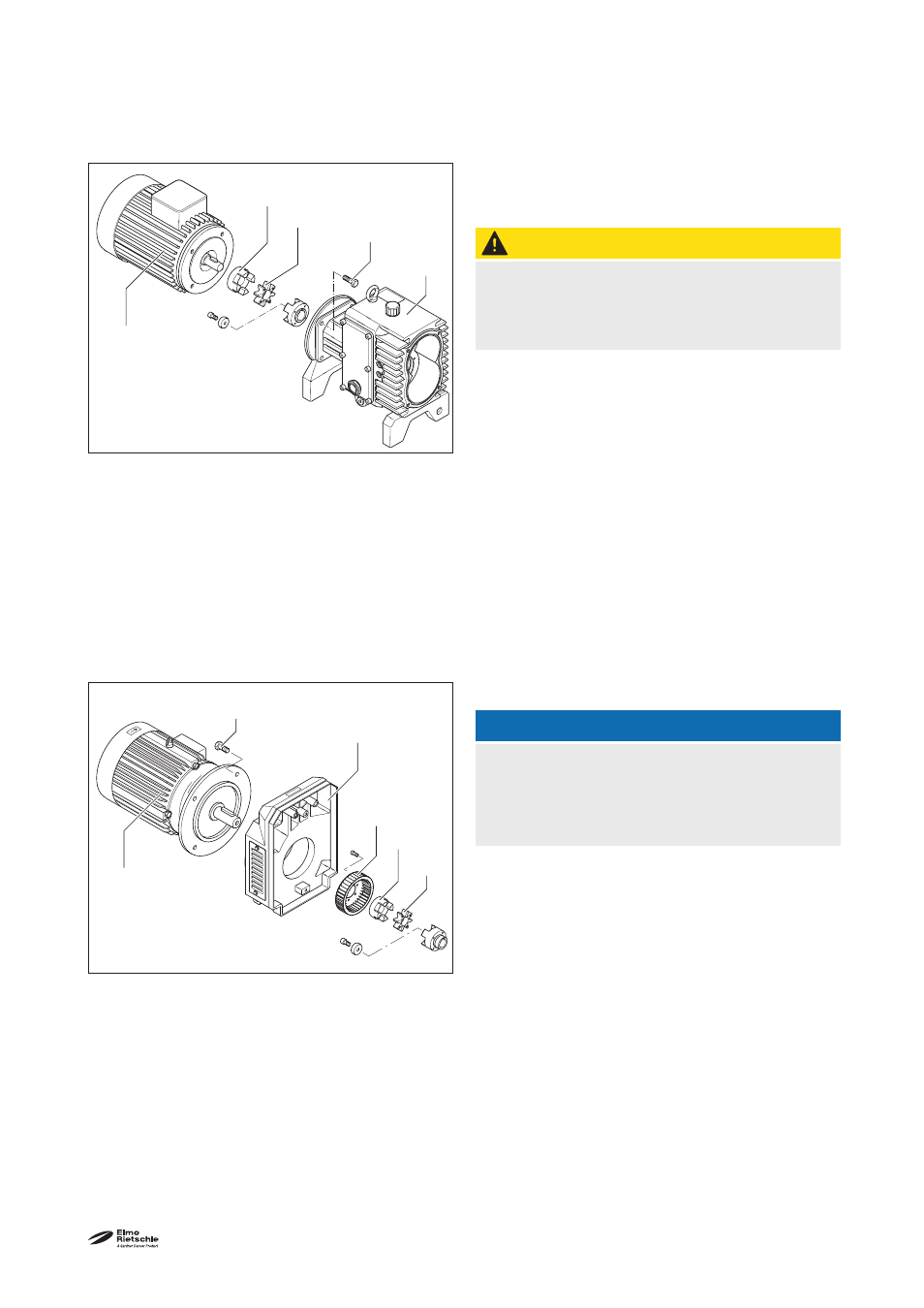

7.2.3 Coupling

The coupling sprocket (Fig. 10/k, 11/k)) is subject to

wear and must be checked regularly (at least once a

year).

CAUTION

Defective coupling sprocket

Defective sprockets may lead to the rotor shaft

breaking.

To check the coupling switch the motor

(Fig. 10/m, 11/m) off and ensure that it cannot be

switched on again.

C-VLR 60

Undo the screws (Fig. 10/s

4

) on the housing fl ange

(Fig. 10/n

1

) . Remove the motor axially with the

half of the coupling on the motor side (Fig. 10/q)

and suspend with the lifting device. If the sprocket

(Fig. 10/k) is damaged or worn, then replace it.

C-VLR 100 - 500

Undo the screws (Fig. 11/s

5

) on the motor fl ange.

Remove the motor with the coupling half on the

motor side (Fig. 11/q) from the fanhousing (Fig. 11/

n

2

) axially and suspend using a lifting tool. If the

sprocket (Fig. 11/k) is damaged or worn, then re-

place it. The fan (Fig. 11/v) should also be checked

for damage from time to time and replaced if neces-

sary.

NOTICE

Frequent starting up and high ambient tem-

perature

The service life of the sprocket (Fig. 10/k, 11/k) is

reduced.

Re-assemble in reverse order.

Fig. 10 Coupling C-VLR 60

k

Coupling sprocket

m

Motor

n

1

Housing

q

Coupling half on the motor side

s

4

Screws

Fig. 11 Coupling C-VLR 100- 500

k

Coupling sprocket

m

Motor

n

2

Fan housing

q

Coupling half on the motor side

s

5

Screws

v Fan