Elmo Rietschle S-VSI 100(01)/300(01)/300(12) User Manual

Page 29

29

www.gd-elmorietschle.com © Gardner Denver Schopfheim GmbH, Gardner Denver Deutschland GmbH

|

Maintenance and repair

1

2

f

4

f

4

h

1

f

3

g

1

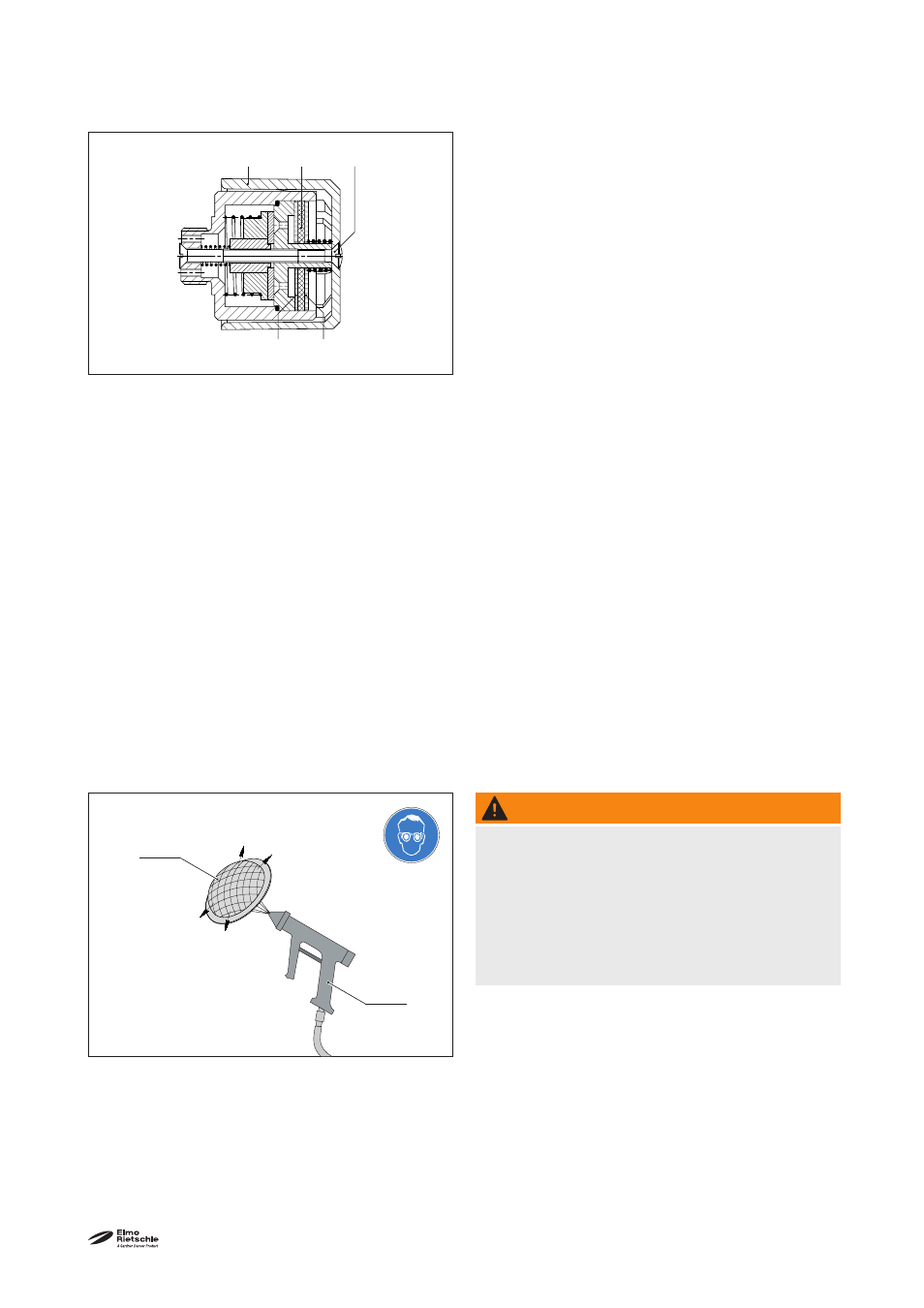

Fig. 11 Blowing out the mesh fi lter

1 Mesh

fi lter

2

Compressed air

Gas ballast valve fi lter:

The pumps S-VSI (12) work with a gas ballast valve

(Fig. 9/U).

The inbuilt fi lter disc Fig. 10/f

3

) and micro fi lter discs

Fig. 10/f

4

) must be cleaned more or less often by

purging depending on how dirty the medium fl ow-

ing through is. By undoing the countersunk screw

(Fig. 10/g

1

) and removing the plastic cover (Fig. 10/

h

1

) the fi lter parts can be removed for cleaning.

Re-assemble in reverse order.

Fig. 10 Gas ballast valve

h

1

Cover

f

3

Filter

disc

g

1

Countersunk

screw

f

4

Micro

fi lter discs

WARNING

Danger of injury when dealing with com-

pressed air

When blowing through with compressed air, solid

particles may be carried along or powder dust swirl-

ing around may cause injury to the eyes.

Therefore, when cleaning with compressed air always

wear goggles and a dust mask.