General information, Precautions / pre-installation, Grinder pump specifications – Liberty Pumps D3696-Series User Manual

Page 2

©Copyright 2011 Liberty Pumps Inc. All rights reserved 2

1

General Information

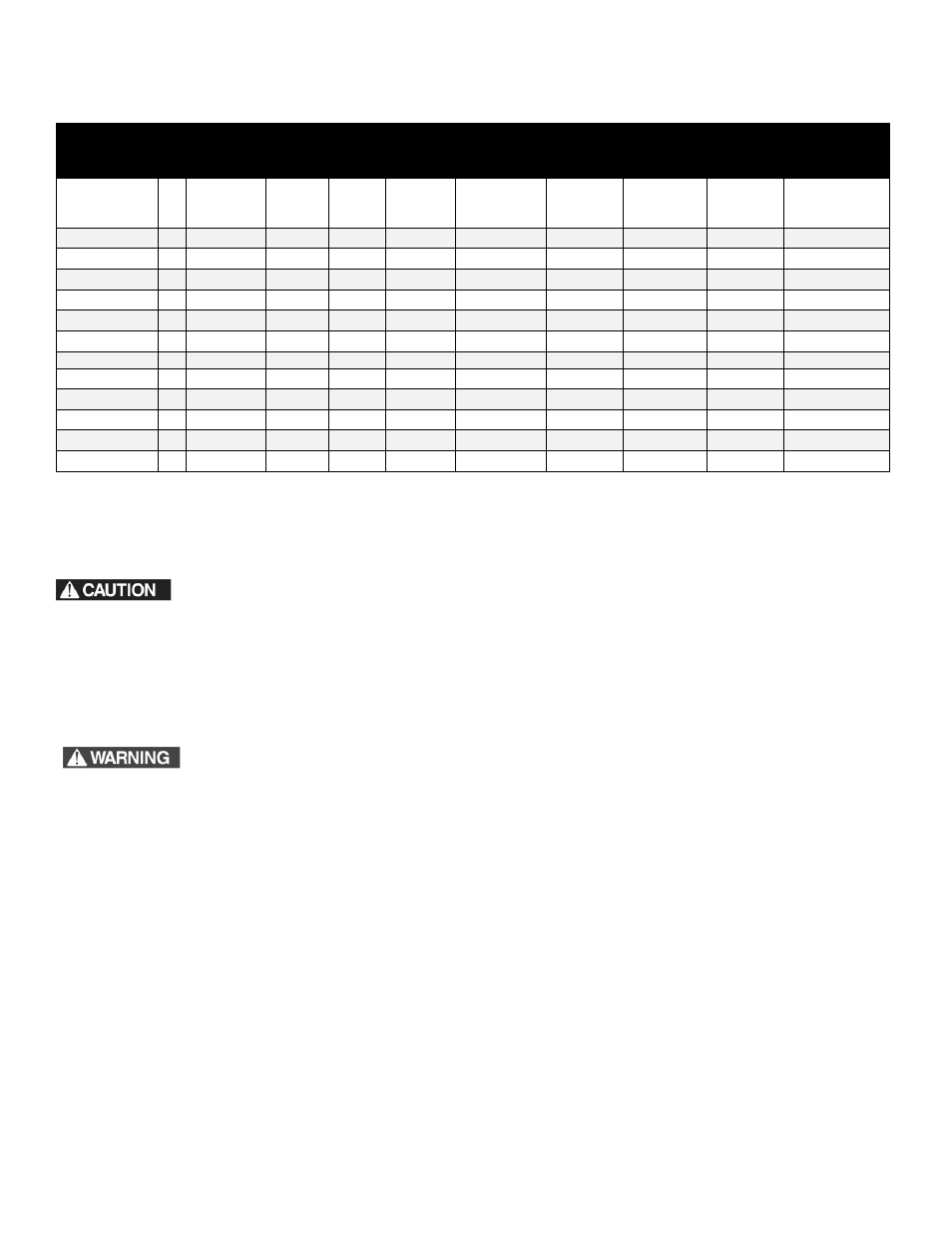

GRINDER PUMP SPECIFICATIONS

MODEL

H

P

VOLTAGE

PHASE

FULL

LOAD

AMPS

LOCKED

ROTOR

AMPS

THERMAL

OVERLOAD

TEMP

STATOR

WINDING

CLASS

SHUT-OFF

HEAD

CORD

LENGTH

FT

DISCHARGE

LSG202A

2

208/230

1

15

53

135

˚C 275°F

B

108’

25

1-

1/4”

LSG202M

2

208/230

1

15

53

135˚C 275°F

B

108’

25

1-

1/4”

LSG202M-C*

2

208/230

1

15

53

135˚C 275°F

B

108’

35

1-

1/4”

LSG203M

2

208/230

3

10.6

61

N/A

B

108’

25

1-

1/4”

LSG204M

2

440/460

3

5.3

31

N/A

B

108’

25

1-

1/4”

LSG205M

2

575

3

4.9

31

N/A

B

108’

25

1-

1/4”

LSGX202A

2

208-230

1

15

53

135˚C 275°F

B

185’

25

1-

1/4”

LSGX202M

2

208-230

1

15

53

135˚C 275°F

B

185’

25

1-

1/4”

LSGX202M-C*

2

208-230

1

15

53

135˚C 275°F

B

185’

35

1-

1/4”

LSGX203M

2

208/230

3

10.6

61

N/A

B

185’

25

1-

1/4”

LSGX204M

2

440/460

3

5.3

31

N/A

B

185’

25

1-

1/4”

LSGX205M

2

575

3

4.9

31

N/A

B

185’

25

1-

1/4”

*Note: LSG202M-C & LSGX202M-C are for external capacitor applications and require the use of control panels fitted with properly

matched capacitors and start relays.

Maximum fluid temperature: 140

F (60

C)

The grinder pump and the control panel are supplied with their own separate Installation/Operation/Maintenance

manuals. Ensure that you have received these manuals, and that you read and understand them prior to installing this unit. Your

familiarity with the grinder pump manual and the control panel manual is critical. This installation manual gives a brief overview of the

system, and deals mainly with inspection and installation of the basin, but it does not cover the specifics of the pump operation or the

control panel operation. If you have any questions, call customer service at (800) 543-2550.

2

Precautions / Pre-Installation

Risk of electric shock. Always disconnect the pump from the power source before handling or making adjustments.

These pumps are not to be installed in locations classified as hazardous in accordance with the National Electric Code, ANSI/NFPA

70.

The electrical connections and wiring for a pump installation should only be made by qualified personnel.

This pump is supplied with a grounding conductor or a grounding-type attachment plug. To reduce the risk of electric shock, be

certain that the grounding conductor is connected only to a properly grounded control panel or, if equipped with a grounding-type

plug, that it is connected to a properly grounded, grounding-type receptacle.

Do not bypass grounding wires or remove ground prong from attachment plugs.

Do not remove cord and strain relief, and do not connect conduit to pump.

Do not use an extension cord.

This system requires separate, properly fused and grounded branch circuit. Make sure the power source is properly sized for the

voltage and amperage requirements of the system, as noted on the nameplate.

The installation must be in accordance with the National Electric Code and all applicable local codes and ordinances.

Sump and sewage pumps often handle materials which could cause illness or disease. Wear adequate protective

clothing when working on a used pump or piping.

Never enter a pump basin after it has been used. Sewage and effluent can emit several gases which are poisonous.