Effluent applications – Liberty Pumps 290-Series User Manual

Page 5

©Copyright 2012 Liberty Pumps Inc. All rights reserved

5

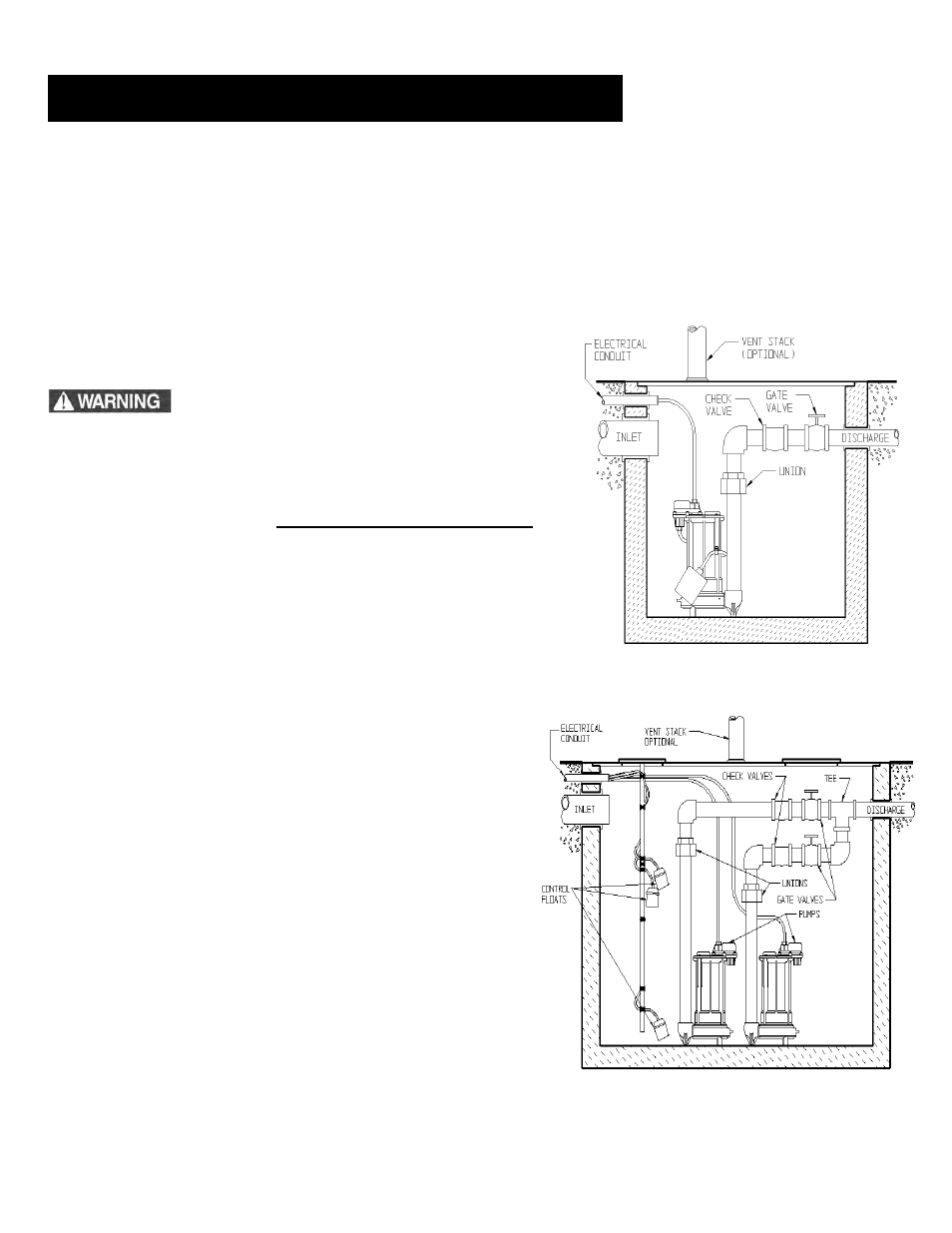

Fig. 2 – Typical Installation Simplex System

This is a recommended installation only.

Variations may apply.

Fig. 3 – Typical Installation Duplex System

This is a recommended installation only.

Variations may apply.

Vertical Magnetic Float (VMF) models (257, 287 and 297) are not recommended for effluent applications due to their short

On/Off cycle. Wide angle float models are better suited for effluent applications and are easily adjustable for different

On/Off levels.

The basin required for effluent applications must be sealed and vented to meet health and plumbing code requirements.

Proper basin size and basin materials for effluent applications vary depending on the type of effluent system and local

codes. Check with your local codes official prior to purchasing and installing the basin. Follow the manufacturer's

recommended guidelines for installation of your specific basin. A minimum diameter of 18" and depth of 24" is required

for proper pump operation, but larger basins are preferred for longer pump cycles and increased switch life. Installation

should be at a sufficient depth to ensure that all plumbing is below the frost line. If this is not feasible, delete the check

valve and size the basin and/or adjust the pump differential to

accommodate the additional backflow.

These pumps are not to be installed in locations

classified as hazardous in accordance with the National

Electric Code, ANSI/NFPA 70, or where prohibited by

local codes.

A.

Simplex (One Pump) Systems (see Fig. 2): Set the pump in place

making sure the float has adequate clearance to the side wall of the

basin. The float must be

free to move throughout its travel and

not contacting the pump body, piping, or other objects. If an optional

control device or float is used, follow the directions for mounting that

accompany the optional control. Connect the discharge pipe to the

pump's threaded discharge. IMPORTANT: DO NOT REDUCE THE

DISCHARGE PIPE SIZE BELOW THAT WHICH IS PROVIDED ON

THE PUMP. Contact Liberty Pumps or other qualified person if you

have questions regarding proper pipe sizes and flow rates. Mount

the basin cover making sure it is properly sealed.

Installation of Discharge: After the pump has been mounted,

install the discharge line. A union should be installed to

facilitate pump removal if necessary. A free-flow swing check

valve is recommended after the union to prevent the backflow

of liquid after each pumping cycle. A gate valve should follow

the check valve to allow periodic cleaning of the check valve or

removal of the pump. The remainder of the discharge line

should be as short as possible with a minimum number of

turns, to minimize friction head loss. Contact Liberty Pumps or

other qualified person if you have questions regarding proper

pipe sizes and flow rates.

(All Liberty effluent/dewatering pumps come equipped with an

air bleed hole in the base of the pump to help prevent airlock.

A small spray of water from this hole is normal while pump is

running.)

B.

Duplex (Two Pump) Systems (see Fig. 3): Set both pumps

in place in the bottom of the basin. The duplex control used

will include 3 or 4 floats that will either be tethered to one of

the discharge pipes or to an independent rod or bracket.

3. Effluent Applications