Dewatering / sump applications – Liberty Pumps 290-Series User Manual

Page 4

©Copyright 2012 Liberty Pumps Inc. All rights reserved

4

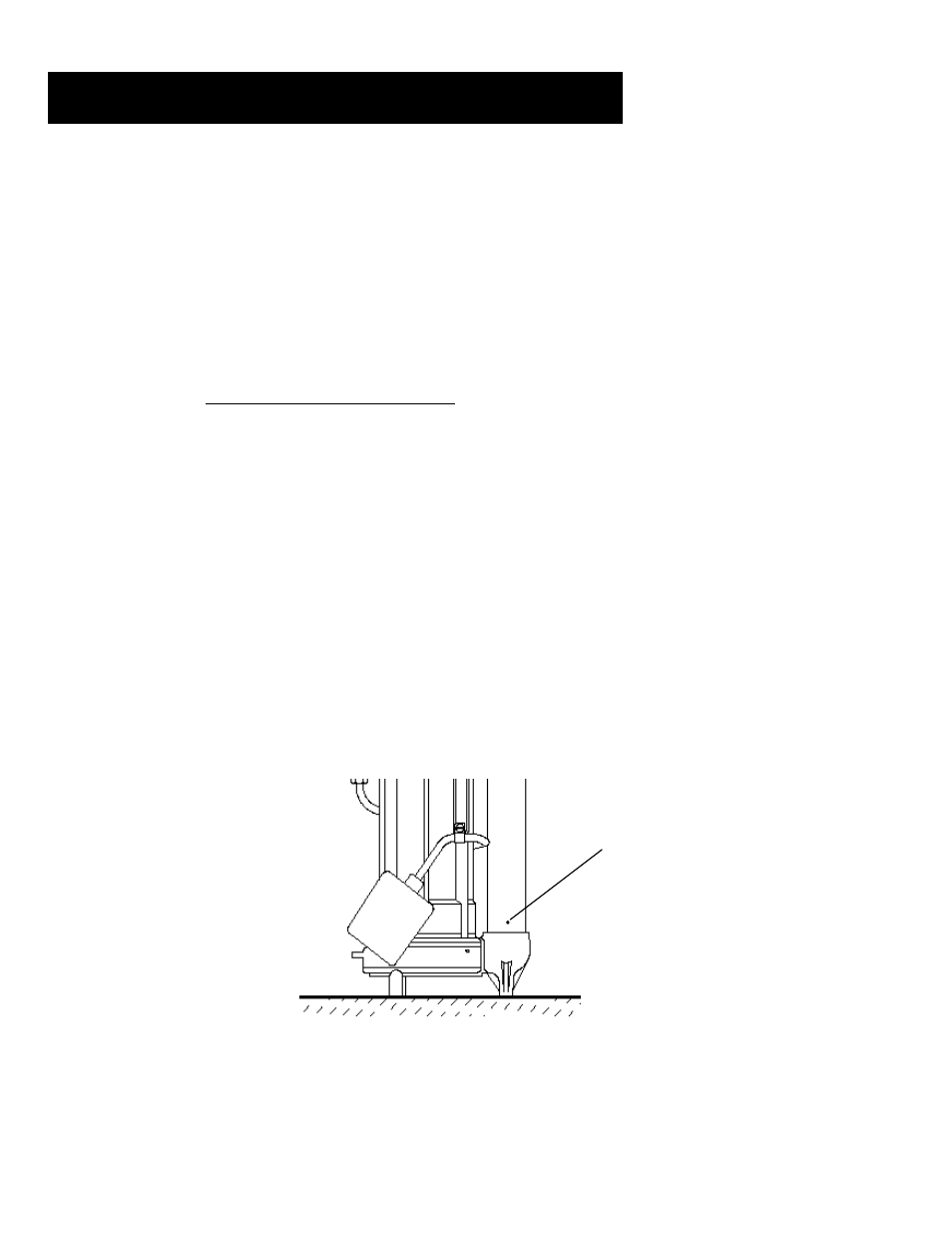

Fig. 1 – Anti-airlock hole position

1. For ordinary ground water pumping applications, a sump pit of not less than 14" in diameter is recommended.

Vertical float (VMF) models (257, 287 and 297) may be used in a minimum 10" diameter sump; however, a larger

diameter pit is preferred as it allows for a longer pump cycle and reduced switch cycling. The minimum depth of the

pit should be 18".

2. If the pit is not already enclosed on the bottom, provide a hard level bottom of bricks or concrete. DO NOT place

the pump directly on earth, gravel or debris since this can cause excessive wear of the impeller and possible

jamming.

“The Brick” (sold by Liberty Pumps as part # 4445000) is a pre-molded stable platform designed to fit

your submersible pump. It raises the pump 2.5” off the bottom of the pit, reducing the potential for jamming from

rocks and debris. Contact your local distributor to order. Remove all debris from the bottom of the sump pit

before installation of the pump. A sump pit cover is suggested for safety and to prevent foreign objects from

entering the pit.

3. Set the pump in the pit making sure the switch has adequate clearance and will not hang-up on the pit wall. The

float must be

free to move throughout its travel and not contacting the pump body, piping, or other objects. A 1-

1/2" threaded discharge is provided for connection of the discharge pipe. Do not reduce the discharge size to

below 1-1/2”. Schedule 40 PVC pipe is recommended; however, flexible discharge hose kits may be used for

temporary installations.

4. Connect the pipe or the discharge hose to the discharge of the pump. HAND TIGHTEN ONLY. Over tightening

may cause the pump housing to crack. Install a union or other means of separating the discharge line just above

the floor to facilitate removal of the pump if necessary. A check valve is recommended just above or in place of

the union to prevent the backflow of water after each pump cycle. (All Liberty effluent/dewatering pumps come

equipped with an air bleed hole in the base of the pump to help prevent airlock. A small spray of water from this

hole is normal while pump is running.)

5. Connect additional piping as needed to direct the discharge to the desired location. Discharge should be kept as

short as possible with a minimum number of turns. Check all connections for security.

6. Install a union or other means of separating the discharge pipe just above the floor to facilitate removal of the

pump if necessary.

A check valve is recommended just above, or in place of, the union to prevent the

backflow of water after each pump cycle.

7. If a check valve is used,

a 1/8” anti-airlock hole should be drilled in the discharge pipe just above the

pump’s discharge outlet to prevent pump “airlock” (see Fig. 1)

8. For added protection, consider the addition of a back-up pump such as

Liberty’s SJ10 SumpJet, as well as an

alarm such as

Liberty’s ALM-2 in applications where loss of pump function could result in property damage. If

an alarm is used, it must be connected to a separate electrical circuit.

2. Dewatering / Sump Applications

Drill 1/8” anti-

airlock hole.

Water spray is

normal.