Troubleshooting table – Liberty Pumps S30-Series User Manual

Page 5

©Copyright 2012 Liberty Pumps Inc. All rights reserved

5

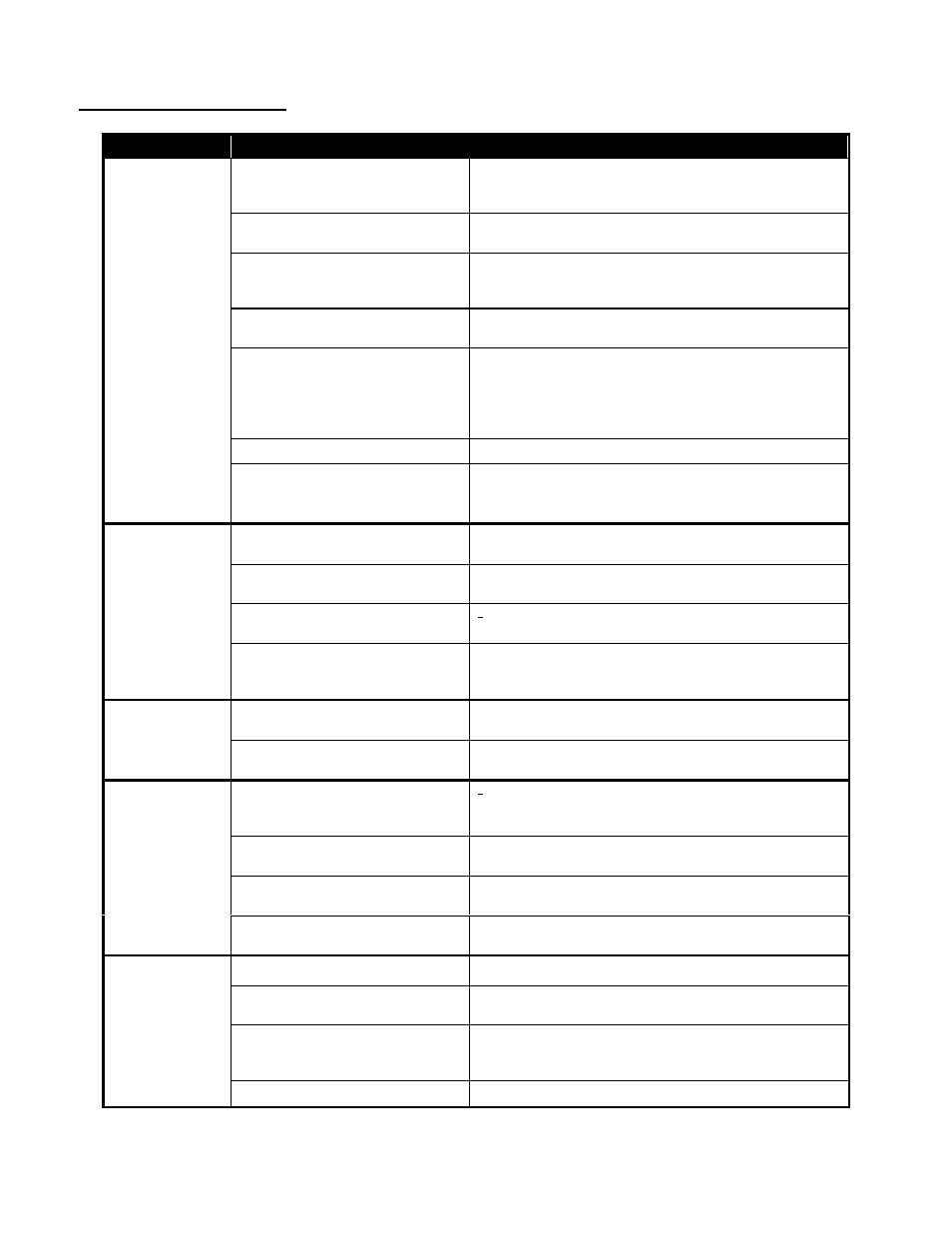

Troubleshooting Table:

Problem

Cause

Correction

Pump will not run

or hum.

Blown fuse or other

interruption of power; improper

voltage.

If blown, replace with properly sized fuse or reset

breaker; if voltage is under 108V, check wiring size.

Remove extension cord if connected.

Water level in pit may be too

low to activate switch.

Add more water to the pit.

Plug on power cord may not

be making contact in

receptacle.

Check security and connection. If receptacle is

corroded, have it replaced by a certified electrician.

Piggyback plugs may not be

connected tightly together.

Tighten connection of plugs.

Switch is defective Model S38

only.

Verify that water level is at least 4” above pump. To

test the switch, plug the power cord directly in to the

electrical receptacle bypassing the piggyback plug. If

pump operates, then the switch needs replacement.

(See Switch-Servicing procedures on page 5).

Motor winding may be open.

Consult factory.

Float switch obstructed Models

S37 and S38.

The float must be free to move unobstructed – if

bound remove debris or position pump to prevent

float from rubbing on side wall of sump.

Pump runs or

hums but does

not remove

water.

Check valve may be installed

backwards or is defective.

Make sure it’s installed properly and flapper in valve

is free to move.

Discharge line may be blocked

or frozen.

Make sure line doesn’t pass through cold areas or

isn’t blocked.

Vertical lift is beyond pump’s

capability.

If possible, try to reduce the discharge head to a

lower height.

Inlet screen of pump is

plugged or the impeller is

jammed.

Remove the pump screen and clean inlet and

impeller.

Pump runs and

removes water

but does not shut

off.

Switch is defective or

obstructed.

Make sure switch is free from obstruction or replace

switch.

Pump has met or exceeded its

maximum lift.

Route discharge piping to a lower level. If this isn’t

possible then a larger pump may be required.

Pump runs but

removes very

little water.

Vertical lift is approaching

pump’s maximum lift capability

of 27’.

If possible, try to reduce the discharge head to a

lower height.

Pump’s inlet is partially

blocked.

Remove volute and make sure inlet is clear of debris.

Discharge line is partially

blocked.

Remove blockage.

Check valve is not opening all

the way.

Remove blockage or make sure check valve is not

defective.

Circuit breaker

trips or fuse

blows when

pump starts.

Fuse or breaker is too small.

A 15-amp breaker should be used.

Other major appliance is on

the same circuit.

Pump should be on its own circuit.

Pump is connected to an

extension cord or wiring is

inadequate.

Have an electrician check for proper wiring.

Defective motor or switch.

Consult factory.