Installation ofpinstalla, Operation installa – Liberty Pumps S30-Series User Manual

Page 3

©Copyright 2012 Liberty Pumps Inc. All rights reserved

3

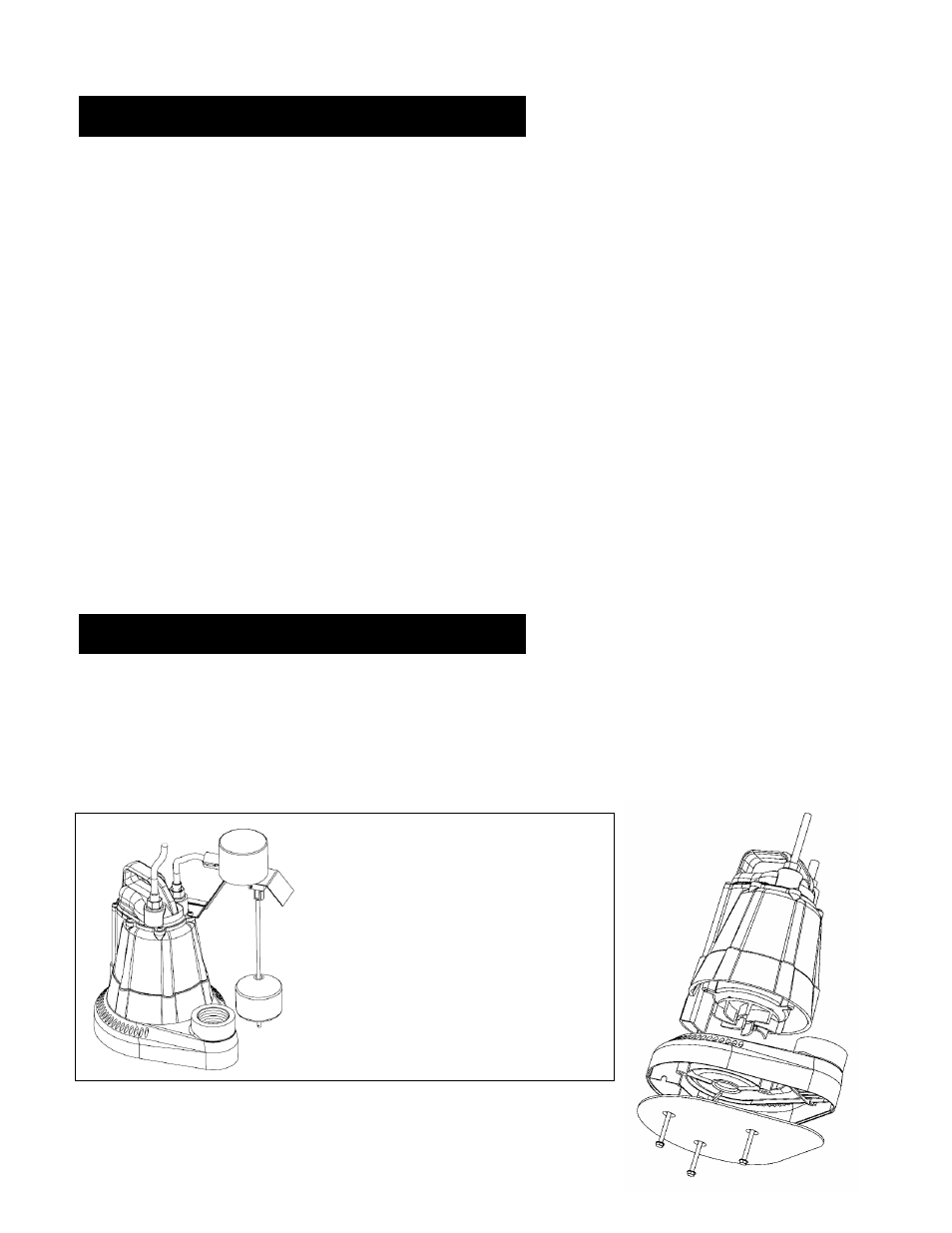

Model S37

has an integrated vertical

float switch. The turn off position can

be adjusted by sliding a rubber

grommet up or down the length of the

float rod.

A.) Removal of the old pump (NOTE: Disconnect pump from power source before handling): Separate the discharge pipe

at either the check valve or at the union. If neither a check valve nor a union is part of the existing discharge pipe, cut the

pipe with a hacksaw and remove the pump (A union or check valve will need to be installed at this cut).

B.) The discharge size is 1-1/2” NPT Do not reduce the discharge size to less than 1-1/4”, as this will affect pump flow and

performance. Schedule 40 PVC pipe is recommended; however, flexible discharge hose kits may be used for temporary

installations.

C.)

Connect the pipe or the discharge hose to the discharge of the pump. HAND TIGHTEN ONLY, over-tightening can damage

the pump discharge.

D.)

Install a union or other means of separating the discharge pipe just above the floor to facilitate removal of the pump if

necessary. A check valve is recommended just above or in place of the union to prevent the back-flow of water

after each pump cycle.

E.) Connect additional pipe as necessary to direct the discharge to the desired location. Discharge should be kept

as short as possible with a minimum number of turns.

F.) Model S37 and S38: When placing the pump in the basin assure that float switch has adequate clearance in pit

and will not interfere with side wall.

G.) For added protection, consider the addition of a back-up pump such as

Liberty’s SJ10 SumpJet, as well as an

alarm such as

Liberty’s ALM-2 in applications where loss of pump function could result in property damage. If

an alarm is used, it must be connected to a separate electrical circuit.

A separate branch circuit, properly fused and grounded, should be provided to the pump. Make sure the power

source is properly sized for the voltage and amperage requirements of the motor as noted on the pump nameplate.

If electrical receptacle is corroded or worn it should be replaced to ensure reliable operation of the pump. The

electrical outlet or panel shall be within the length limitations of the pump power cord and at least 4 feet above floor

level to minimize possible hazards from flood conditions. Check to make sure installation is in accordance with the

National Electric Code and all applicable local codes and ordinances. Wiring extended over greater distances must

be in accordance with NEC requirements. DO NOT USE AN EXTENSION CORD.

3. Installation

ofPInstalla

&hgjhjhgj&Troubl

eshootingTroubleshooting

&Troubleshooting&Troubl

eshooting&Troubleshootin

g&Troubleshooting&Trou

bleshooting

4. Operation

Installa

&hgjhjhgj&Troubles

hootingTroubleshooting&

Troubleshooting&Troubles

hooting&Troubleshooting

&Troubleshooting&Troubl

eshooting