Gorman-Rupp Pumps SF4A-X 1531245 and up User Manual

Page 11

SF SERIES X‐PROOF PUMPS

OM-06629

PAGE B - 2

INSTALLATION

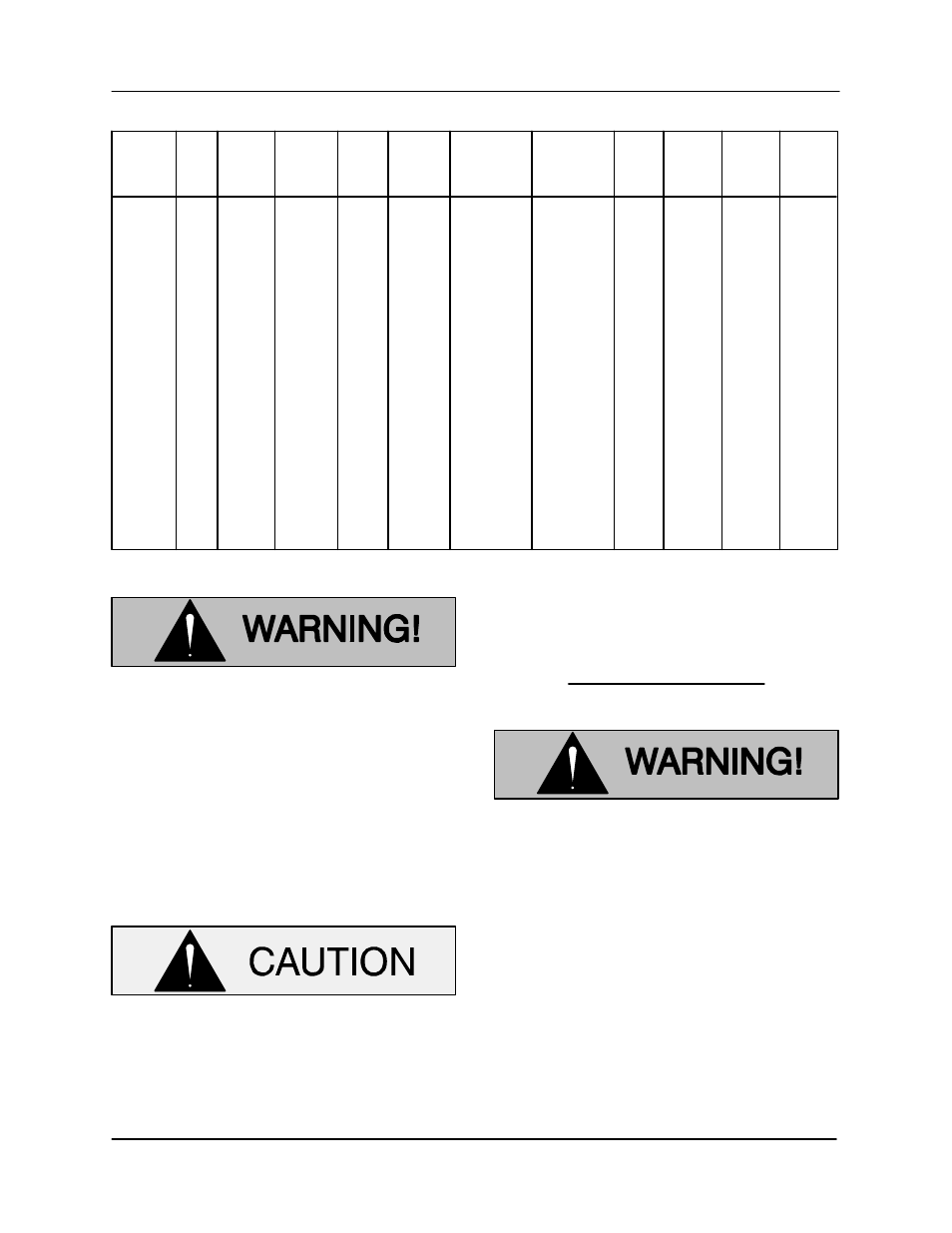

Table B‐1. Pump Motor Specifications

G‐R

Full

Locked

LR

Motor

HP

Volts

PH

Hz

RPM

Load

Rotor

Code Start

Design Service

Frame

Amps

Amps

kVA

Factor

4A

15

208

3

60

1750

46.8

416

L

149.9

A

1.15

4A

15

230

3

60

1750

42.4

376

L

149.8

A

1.15

4A

15

460

3

60

1750

21.2

188

L

149.8

A

1.15

4A

15

575

3

60

1750

17.0

150

L

149.4

A

1.15

4A

20

208

3

60

1750

58.6

416

J

149.9

A

1.15

4A

20

230

3

60

1750

53.0

376

J

149.8

A

1.15

4A

20

460

3

60

1750

26.5

188

J

149.8

A

1.15

4A

20

575

3

60

1750

21.2

150

J

149.4

A

1.15

4A

24

208

3

60

1750

63.4

416

G

149.9

A

1.0

4A

24

230

3

60

1750

61.6

376

G

149.8

A

1.15

4A

24

460

3

60

1750

30.8

188

G

149.8

A

1.15

4A

24

575

3

60

1750

24.6

150

G

149.4

A

1.15

5A

30

460

3

60

1750

36.6

246

H

196.0

B

1.15

5A

30

575

3

60

1750

29.3

197

H

196.2

B

1.15

6A

50

460

3

60

1750

60.0

425

H

338.6

A

1.15

6A

50

575

3

60

1750

48.0

340

H

338.6

A

1.15

7A

75

460

3

60

1750

86.0

542

G

431.8

B

1.15

7A

75

460

3

60

1750

69.0

434

G

432.2

B

1.15

PUMP INSTALLATION

When installing or servicing the pump

or controls, follow all requirements for

the installation of wiring or electrical

equipment in hazardous locations as

outlined in the National Electric Code.

When entering the pump wet well for in

stallation or service, follow all safety re

quirements for confined space entry.

Failure to observe these requirements

could result in injury or death to person

nel.

Do not allow the free end of the power

cable to enter the liquid being pumped.

The free end of the cable must be kept dry

to prevent liquid from wicking through the

cable and into the motor.

NOTE

Refer to the performance curve on the pump Spe

cification Data Sheet when determining the most ef

ficient piping installation. The recommended

maximum submergence depth is 65 feet.

Lifting

Death or serious personal injury and

damage to the pump or components

can occur if proper lifting procedures

are not observed. Make certain that

hoists, chains, slings or cables are in

good working condition and of suffi

cient capacity and that they are posi

tioned so that loads will be balanced

and the pump or components will not be

damaged when lifting. Do not attempt to

lift this pump by the motor or control

cables, or the piping. Attach proper lift

ing equipment to the lifting bail fitted on

the pump. Lift the pump or component