Gorman-Rupp Pumps SF6B All serial numbers User Manual

Page 10

OM-06548

SF SERIES

PAGE B - 2

INSTALLATION

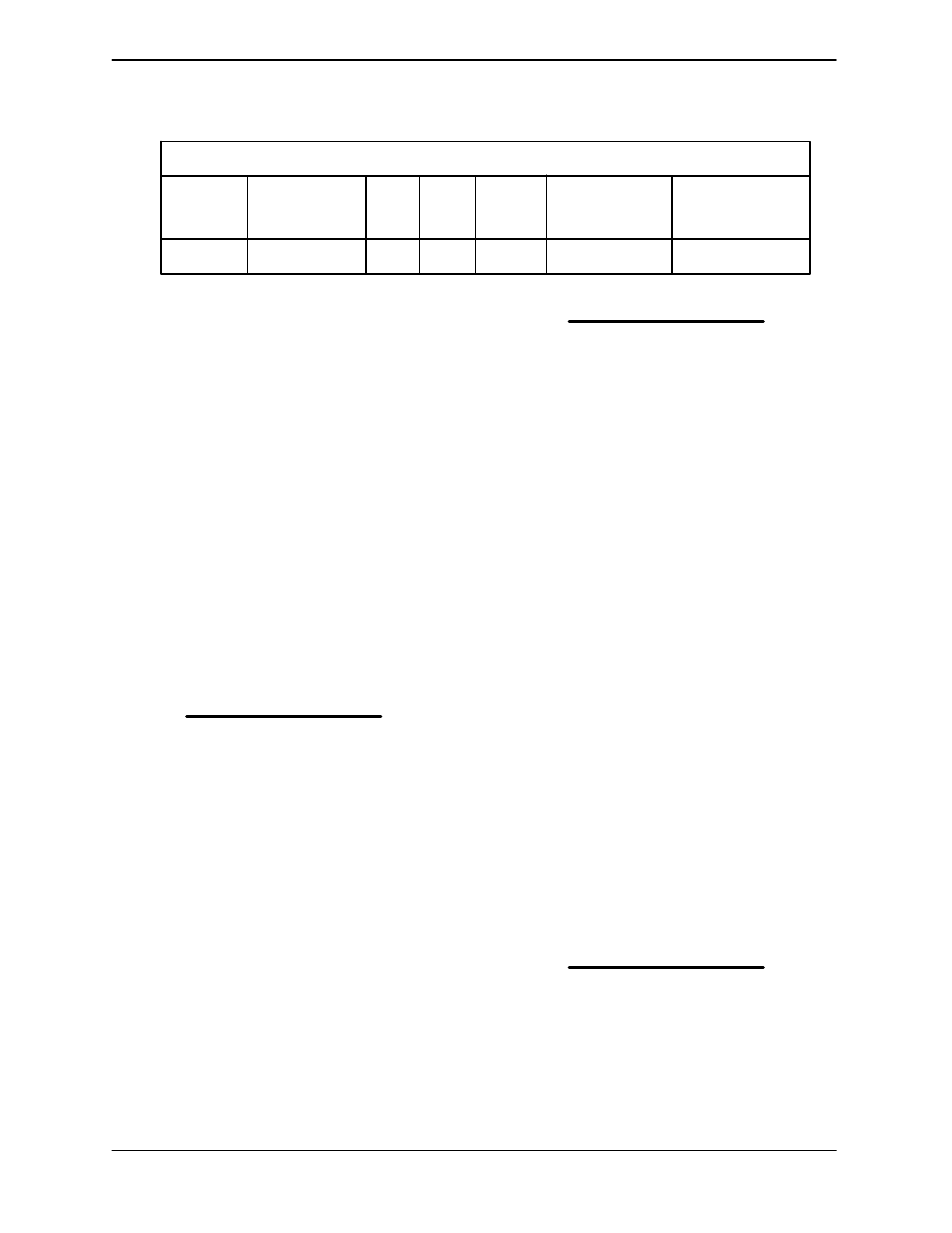

See Table B-1 for motor specifications.

TABLE B-1. PUMP MOTOR SPECIFICATIONS

MODEL

VOLTAGE/

PHASE

SIZE

MOTOR

RPM

MAX

LOAD

AMPS

H.P.

LOCKED

ROTOR

AMPS

SF6B

460/575

6”

75.0

1750

86.0/69.0

542.0/434.0

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer‐installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

Positioning the Pump

NOTE

Before installing and operating the pump, check

the direction of impeller rotation to ensure that the

pump is properly wired at the control box. See IM

PELLER ROTATION, SECTION C.

This pump may be mounted on guide rails or

cables for use with optional discharge elbow/base

plate kits, or it may be mounted on a trash stand

with an optional discharge elbow.

If the pump is configured for a guide rail/guide

cable application, the pump will be equipped with

a rail guide shoe which connects to the discharge

optional elbow/baseplate. When lowered into

place, the pump is automatically and securely con

nected to the elbow/baseplate and the piping sys

tem. For information on installing the guide rails,

see the literature accompanying them.

NOTE

When engaging the guide shoe and elbow/base

plate, make sure that the connection is not impeded

by mounting hardware, and that the guide shoe is

fully seated in the baseplate.

To install a pump configured for a guide rail/guide

cable application, engage the guide shoe at the

top of the guide rails and use a suitable lifting de

vice attached to the lifting handle to lower the

pump into the wet well. When the pump and guide

shoe engages the discharge elbow/baseplate, it

will form an automatic seal.

If the pump is mounted on a trash stand, secure a

discharge hose or pipe to the optional discharge

elbow and use a suitable lifting device attached to

the lifting handle to lower the pump into the wet

well.

Make certain that the pump and stand sit level in

the wet well.

Regardless of the installation configuration, the

maximum recommended submergence depth

is 65 feet (20 meters).

After installation in the wet well, reel in any slack in

the cables so that they are not dragged into the

pump suction.

Piping

NOTE

Refer to Pump Performance in OPERATION -

SECTION C when determining the most efficient

piping installation.

No suction piping is required in a standard sub

merged operation.

Either hose or rigid pipe may be used to make dis

charge connections. The discharge line must be

independently supported to avoid vibration and

strain on the pump. For maximum pumping capac