Gorman-Rupp Pumps SFV4B 1468408 and up User Manual

Page 20

OM-06402

SF SERIES

PAGE C - 6

OPERATION

burns and injuries. If overheating of the

pump occurs:

1. Stop the pump immediately.

2. Ventilate the area.

3. Allow the pump to completely cool.

4. Check the temperature before ser

vicing.

5. Vent the pump slowly and cau

tiously

6. Refer to instructions in this manual

before restarting the pump.

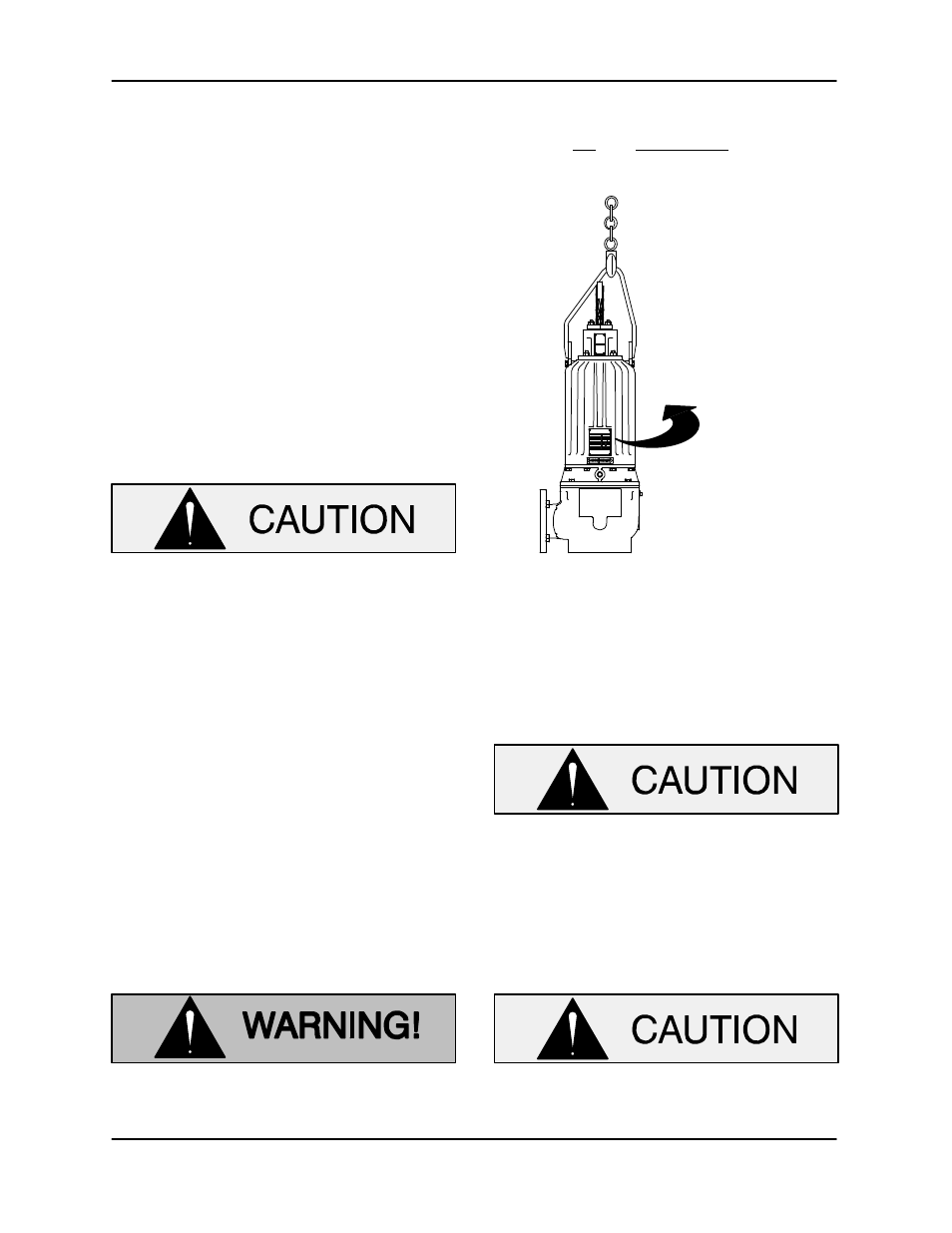

Impeller Rotation

Check impeller rotation as follows before operation

to ensure that the impeller is rotating in the correct

direction.

While checking impeller rotation, secure

the pump to prevent the power cable from

coiling.

Suspend the pump from the lifting device fitted on

the pump. Apply power briefly and note the direc

tion of pump kickback. As viewed from the top, the

pump should kick in a counterclockwise direc

tion; this will indicate that impeller rotation is cor

rect.

If the pump kicks in a clockwise direction, impeller

rotation is incorrect. If the pump is powered by a

three‐phase motor, have a qualified electrician in

terchange the control box connections of any two

pump motor power leads. Re‐check pump kick

back; it should now be in a counterclockwise direc

tion.

If rotation is incorrect on a single‐phase motor, con

tact the factory before installing the pump.

The electrical power used to operate

this pump is high enough to cause inju

ry or death. Make certain that incoming

power is off and locked out before inter

changing motor leads.

DIRECTION OF

KICKBACK

AT STARTUP

Figure C-1. Checking Pump Rotation

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting

Do not attempt to operate the pump until

impeller rotation has been checked; im

proper rotation will affect pump perform

ance and may damage the pump.

Follow the instructions accompanying the control

box, start the pump, and run any recommended

checks.

Do not start the pump more than 10 times

per hour. If the pump motor does not cool