Gorman-Rupp Pumps SFV3B 1473390 and up User Manual

Page 44

OM-06400

SF SERIES

PAGE E - 17

MAINTENANCE AND REPAIR

Hoisting Bail Installation

(Figure E-1)

If the hoisting bail (13) was removed in order to re

move the terminal housing assembly (10) position

the bail over the motor housing so the holes for the

mounting hardware align. Apply “Never‐Seez” or

equivalent compound to the threads of the caps

crews (8) and secure the bail to the motor housing

with the hardware (8 and 12). Torque the caps

crews to 28 ft. lbs. (327 in. lbs. or 3,8 m. kg.).

VACUUM TESTING

To ensure the water‐tight integrity of the pump, the

motor and seal cavities must be vacuum tested any

time the seal(s) and/or motor are serviced.

Use a manometer with a range of 30 to 0 to 30 inch

es of mercury to perform the test. Do not use a vac

uum gauge. Vacuum gauges are not sensitive

enough to detect minor leaks.

It is recommended that a vacuum pump be used to

draw the vacuum on the cavities. If a vacuum pump

is not available, a compressor/venturi system may

be used. If the compressor/venturi cannot draw

the higher vacuum level shown in Table E-1, draw

the motor cavity vacuum down as far as the system

will allow, then draw the seal cavity down so the dif

ferential between the two cavities is the same as

the differential between the vacuum readings

shown in the table.

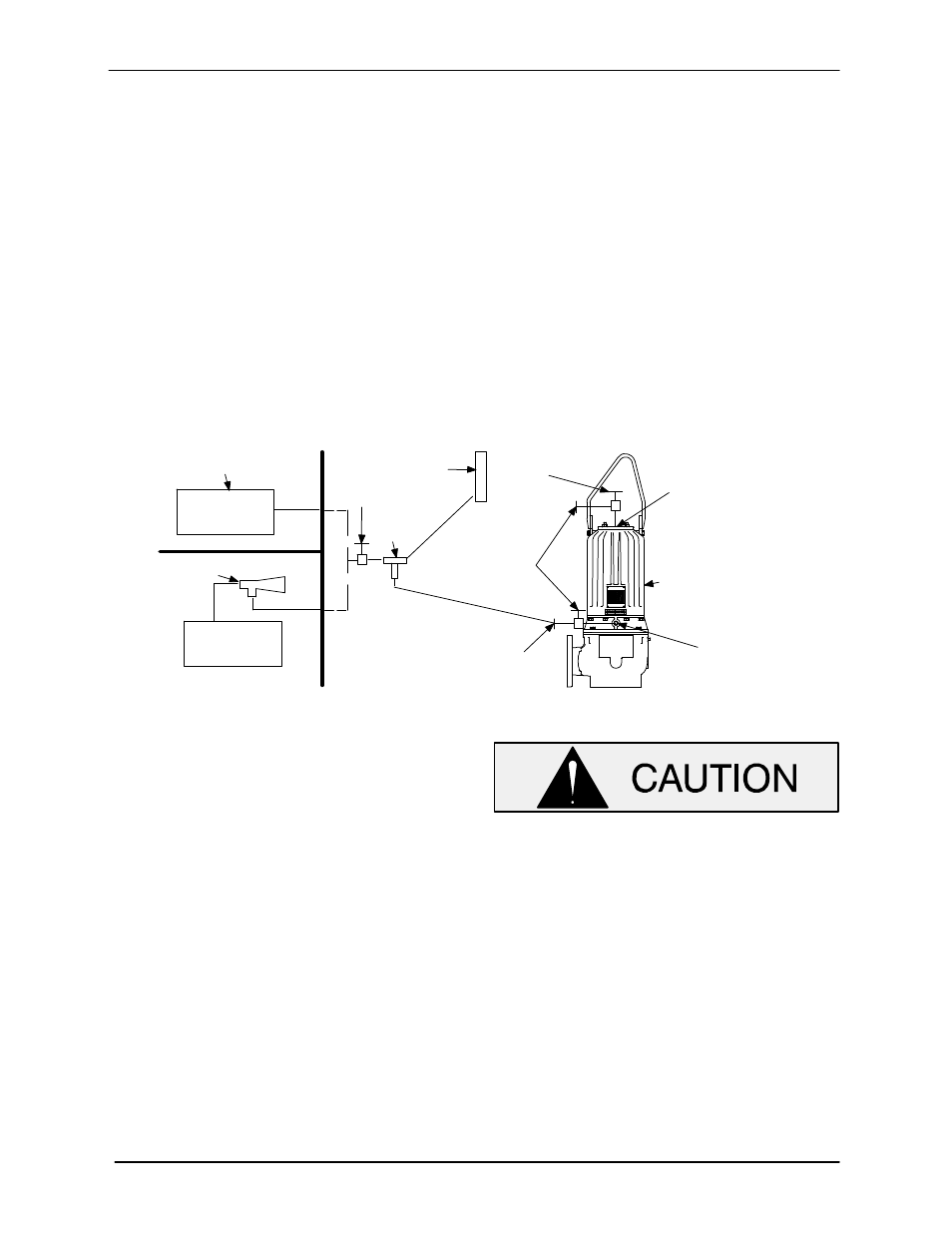

Tee

Manometer

Vacuum Pump

Submersible

Pump

Full-Closing

Ball-Type

Shutoff Valve

Quick Disconnect

Fitting

Quick Disconnect

Fitting

Air Compressor

Venturi

Seal Cavity

Fill/Drain

Motor Vacuum

Test Plate

S.O. Valve

Figure E-4. Vacuum Test System

Seal Cavity Testing

If the water‐tight integrity of the motor was not dis

turbed during disassembly, the seal cavity can be

tested without testing the motor.

Drain all of the oil from the seal cavity before per

forming the test. Oil within the cavity will be drawn

into the system, resulting in damage to the vacuum

pump or manometer.

See Figure E-4 and connect the vacuum pump or

compressor/venturi system directly to the pump at

the hole for the seal cavity drain plug (7, Figure

E-2).

Draw the seal cavity vacuum down to not more

than 10 In. Hg. and hold for 10 minutes. If no

change in vacuum reading is detected, proceed

with LUBRICATION.

Do not draw the seal cavity vacuum below

10 In. Hg. Lower vacuum can cause sepa

ration of the seal faces and/or unseating of

the upper seal stationary seat, resulting in

seal leakage.

Seal and Motor Cavity Testing

Connect the vacuum pump or compressor/venturi

system to the pump as shown in Figure E-4.

If the compressor/venturi cannot draw the higher

vacuum level shown in Table E-1, draw the motor

cavity vacuum down as far as the system will allow,

then draw the seal cavity down so the differential

between the two cavities is the same as the differ