Gorman-Rupp Pumps SFV3B 1473390 and up User Manual

Page 11

SF SERIES

OM-06400

PAGE B - 3

INSTALLATION

shoe engages the discharge elbow/baseplate, it

will form an automatic seal.

If the pump is mounted on a trash stand, secure a

discharge hose or pipe to the optional discharge

elbow and use a suitable lifting device attached to

the lifting handle to lower the pump into the wet

well.

Make certain that the pump and stand sit level in

the wet well.

Regardless of the installation configuration, the

maximum recommended submergence depth

is 65 feet (20 meters).

After installation in the wet well, reel in any slack in

the cables so that they are not dragged into the

pump suction.

Piping

NOTE

Refer to Pump Performance in OPERATION -

SECTION C when determining the most efficient

piping installation.

No suction piping is required in a standard sub

merged operation.

Either hose or rigid pipe may be used to make dis

charge connections. The discharge line must be

independently supported to avoid vibration and

strain on the pump. For maximum pumping capac

ity, keep the line as short and straight as possible.

Elbows and fittings used in a discharge line in

crease friction losses; minimize their use.

It is recommended that a check valve or throttling

valve be installed in the discharge line to control si

phoning or back flow when the pump is shut off.

ELECTRICAL CONNECTIONS

Install and operate this pump in accor

dance with the National Electrical Code

and all local codes. Have a qualified

electrician perform all checks and con

nections in this section.

Never attempt to alter the length of the

pump motor cable or to repair it with a

splice. The power cable and pump mo

tor must be kept completely waterproof.

Serious damage to the pump and injury

or death to personnel can result from

any alteration to the cable.

Field Wiring Connections (Incoming Power)

Field wiring is not provided with this pump, and

must be supplied by the user. The field wiring must

be of the proper size and type to ensure an ade

quate voltage supply to the pump. Voltage avail

able at the motor must be within the range indi

cated in Table B-2.

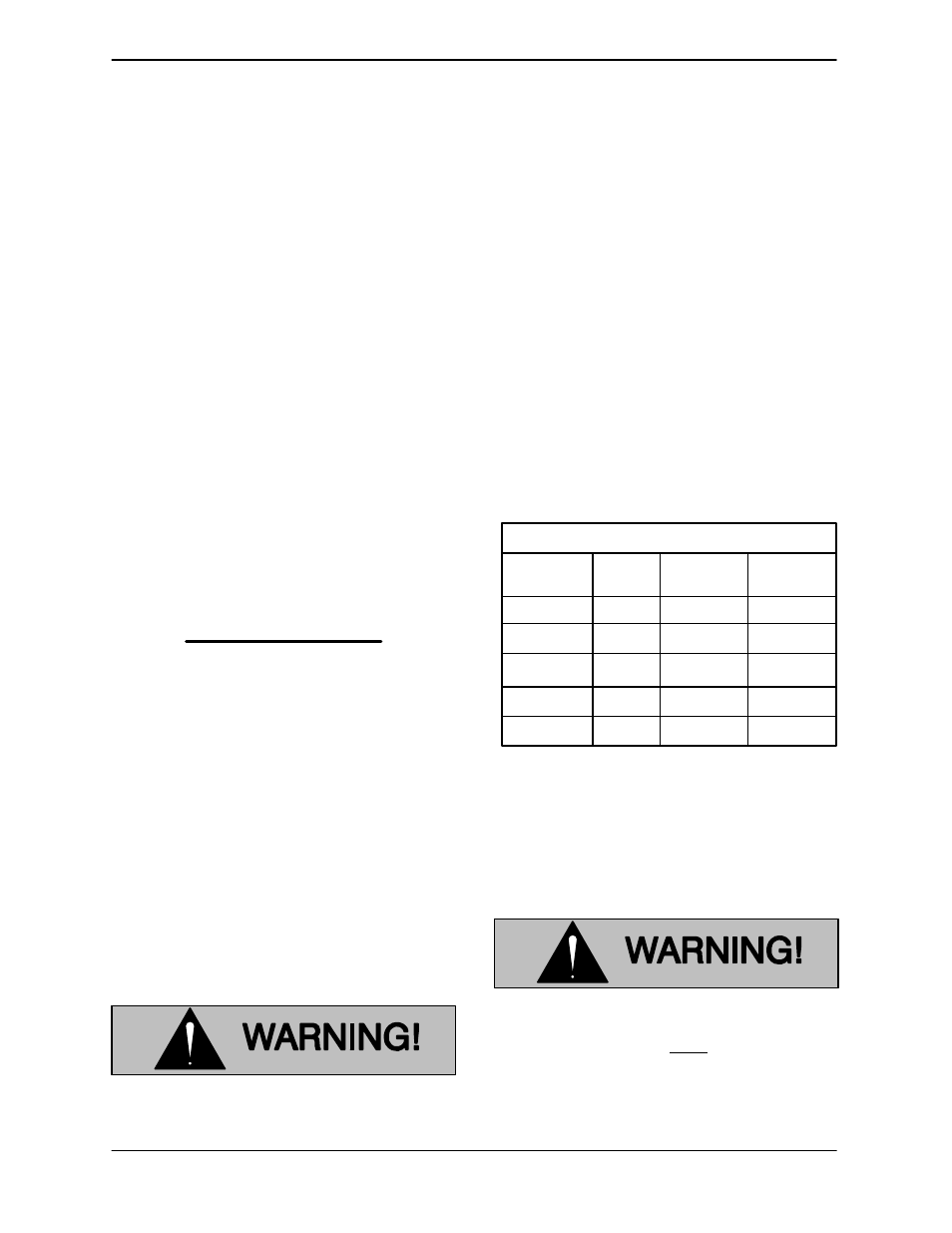

TABLE B-2. MOTOR VOLTAGE LIMITS

NOMINAL

VOLTAGE

3

230

207

253

PHASE

MINIMUM

VOLTAGE

MAXIMUM

VOLTAGE

3

460

414

506

3

575

517

632

3

208

187

229

1

230

207

253

Use conduit cable clamps to secure the incoming

field wiring to the control box. Make certain all con

nections are tight. If necessary, support the cable

weight to prevent excessive strain on cable clamps

and cable.

Dual Voltage

230V and 460V versions of these pumps

are dual‐voltage; however, they are

wired at the factory only for the voltage

shown on the nameplate. Do not attempt

to change the voltage in the field. If de

sired to have the voltage changed, re