Figure e-5. motor vacuum test plate, Lubrication – Gorman-Rupp Pumps SFV4D 1468407 and up User Manual

Page 43

SF SERIES

OM-06404

MAINTENANCE AND REPAIR

PAGE E - 18

the upper seal stationary seat, resulting in

seal leakage.

Seal and Motor Cavity Testing

Connect the vacuum pump or compressor/venturi

system to the pump as shown in Figure E-4.

If the compressor/venturi cannot draw the higher

vacuum level shown in Table E-1, draw the motor

cavity vacuum down as far as the system will allow,

then draw the seal cavity down so the differential

between the two cavities is the same as the differ

ential between the vacuum readings shown in the

table.

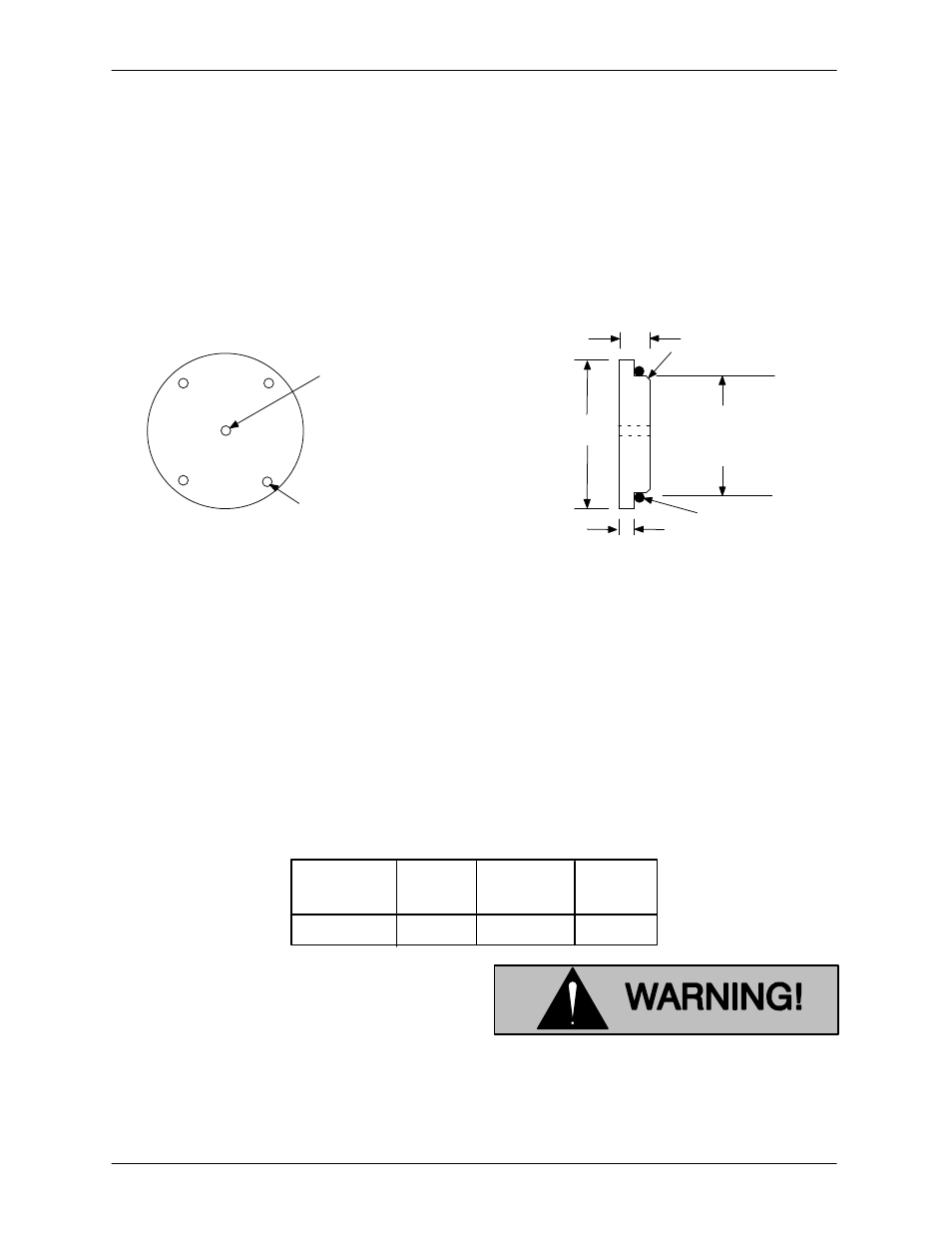

To vacuum test the motor cavity, the terminal hous

ing assembly must be replaced with a test plate.

Make the test plate as shown in Figure E-5 below,

install the terminal housing O‐ring under the test

plate, then proceed with vacuum testing.

.438” (11,1 mm) dia. drill

thru. Tap .250‐18 NPT.

12 mm dia. drill thru (4) holes

equally spaced on a 4.72 (120 mm)

diameter bolt circle.

Install terminal

housing O‐ring

for test.

3.749 - 3.750 in

(95,22 - 95,25 mm)

1.5 in.

(38,1 mm)

.75 in.

(19,1 mm)

5.5 in.

(139,7 mm)

Make from commercially available steel plate.

45

_ x 1/8” (3,1 mm)

Chamfer

Figure E-5. Motor Vacuum Test Plate

Install full‐closing ball‐type shutoff valves with

quick‐disconnect fittings in the pipe plug holes in

both the motor and seal cavities. Test the motor

cavity for its full duration first, then use the shutoff

valve to maintain the motor cavity vacuum while

testing the seal cavity. The motor cavity vacuum

must be higher than the vacuum in the seal cavity

to prevent separation of the seal faces or unseating

the stationary seal seat between the seal and mo

tor cavities.

Figure E-4 shows a simple schematic for setting

up either a vacuum pump or a venturi/compressor

test system.

Table E-1 shows the vacuum to be drawn on each

cavity, and the duration to maintain each vacuum

reading. Any change in vacuum reading during

the test indicates a leak which must be identified

and corrected before putting the pump back into

service.

Table E-1. Vacuum Test Data

Seal Cavity

Vacuum

(In. Hg.)

Motor Cavity

Vacuum

(In. Hg.)

Duration

(Minutes)

Duration

(Minutes)

20

3

30

1

LUBRICATION

Seal Cavity

Check the oil level in the seal cavity before initial

startup, after the first two weeks of operation, and

every month thereafter.

Check the oil level only when the pump

is cool. If the oil level plug is removed

when the pump is hot, pressure in the

seal cavity can cause hot oil to be

ejected as the plug is removed.