Gorman-Rupp Pumps SE2C3A 115V 1P 1483930 and up User Manual

Page 15

SE SERIES

OM−06493

PAGE C − 3

OPERATION

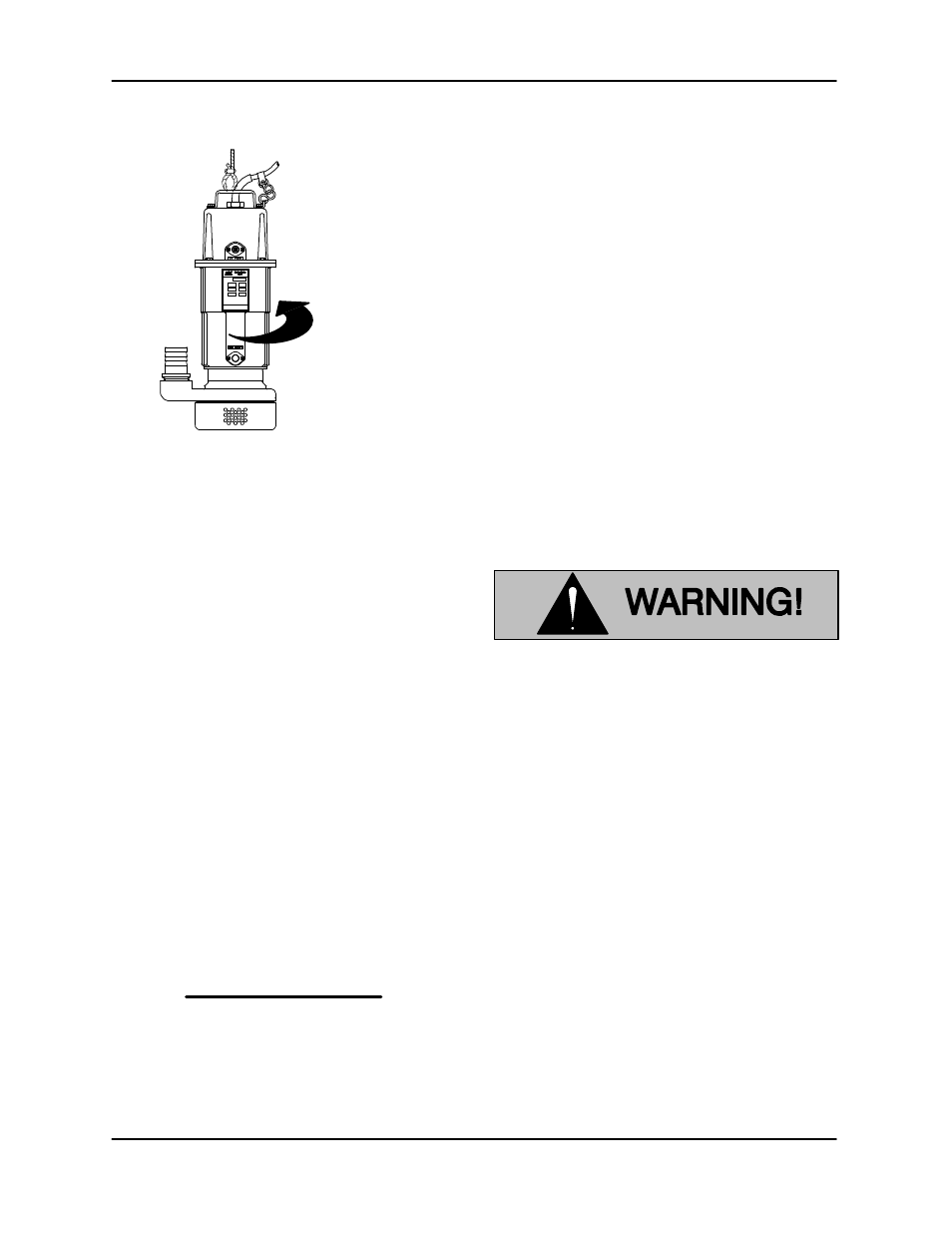

DIRECTION OF

KICKBACK

AT STARTUP

Figure C-1. Checking Pump Rotation

STARTING, STOPPING, AND

OPERATIONAL CHECKS

Starting And Stopping

Pump operation is controlled by the built-in liquid

sensing devices. When liquid level reaches the on-

point (upper) device, the pump will switch on and

continue to run until liquid level falls below the off-

point (lower) device.

NOTE

Distilled water or uncontaminated rain water may

fail to provide conductivity necessary to trigger the

automatic liquid level sensing devices built into the

pump. If this occurs, ground the on-point assembly

to convert the pump to manual operation, and

install a float level control system.

It is recommended that a check valve or throttling

valve be installed in the discharge line if there is any

possibility of siphoning or back flow when the

pump is shut off.

Operational Checks

Check the pump for proper operation when first

started and periodically thereafter to identify minor

problems.

Check the pump for unusual noises or excessive

vibration while it is operating. If noise or vibration

is excessive, stop the pump and refer to the trou-

bleshooting chart for possible causes.

Check the pump strainer screen for clogging

caused by stones, sticks, or other debris. Clean

the strainer screen when required. In some cases,

stopping the pump momentarily may back flush

the strainer screen, purging most of the debris

from it. If this fails to clean the screen, remove the

pump from the sump and remove the debris manu-

ally. See PUMP DISASSEMBLY in the Mainte-

nance And Repair manual.

Never introduce air or steam pressure

into the pump casing to remove a block-

age. This could result in personal injury

or damage to the equipment. If back-

flushing is absolutely necessary, limit

liquid pressure input to 50% of the maxi-

mum permissible operating pressure

shown in the pump performance curve

(refer to the accompanying Parts List

Manual).

Check the pump for overheating. Overheating can

occur if the pump is made to start and stop repeat-

edly without time to cool off between starts, the liq-

uid level is allowed to fall too low to sufficiently cool

the motor, or if the circuit breaker or fuse fails to

provide adequate protection. Operating the pump

against a closed discharge valve for an extended

period will also cause the pump to overheat.

Check the oil level(s) as indicated in the following

LUBRICATION section.