Gorman-Rupp Pumps PA10A60-4045H 1452219 thru 1484415 User Manual

Page 12

PA SERIES

OM−06344

PAGE B − 5

INSTALLATION

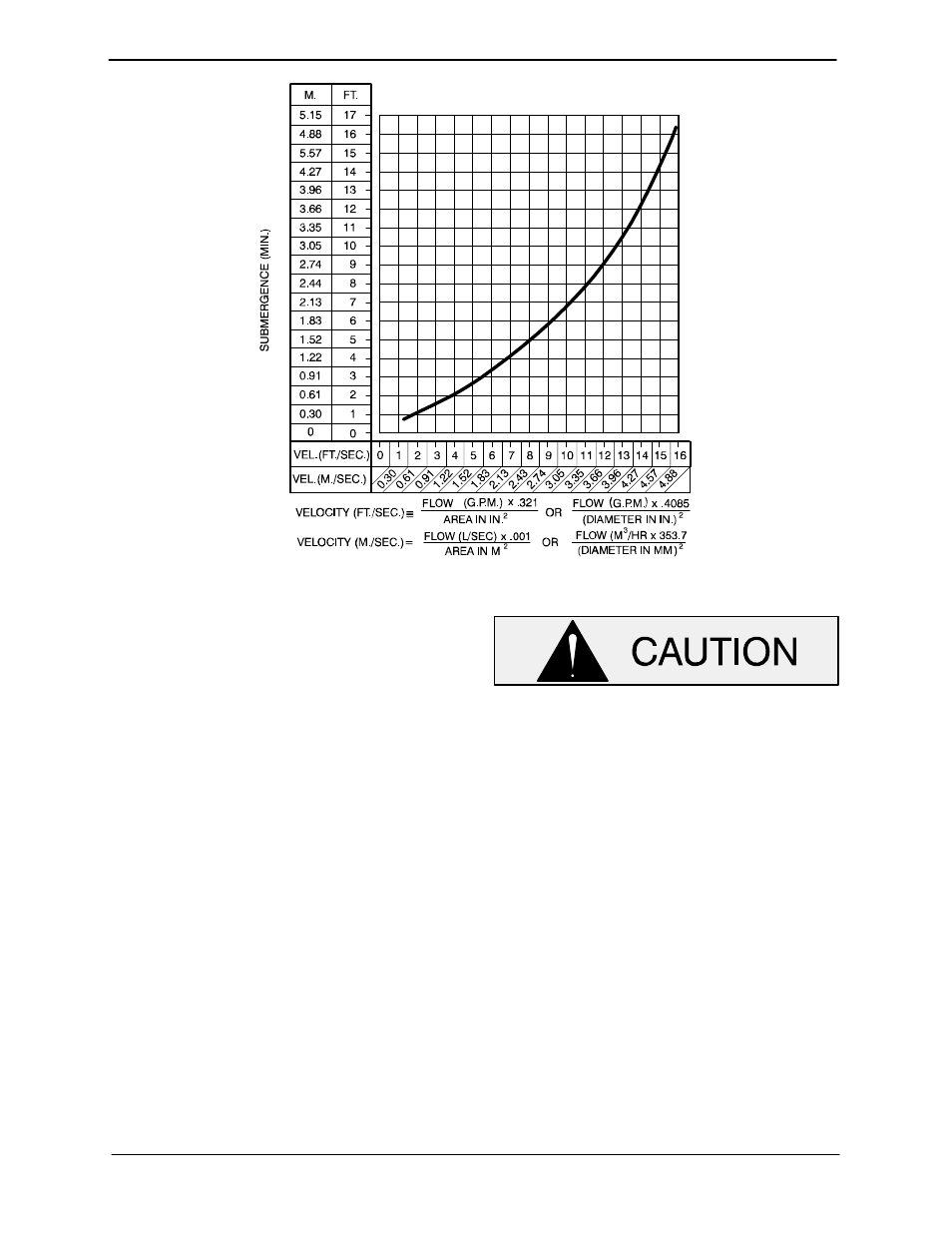

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si-

phon breaker is used in the line. Otherwise, a si-

phoning action causing damage to the pump

could result.

Valves

This pump is designed with a check valve in the

discharge line.

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve be installed in the discharge line

to protect the pump from excessive shock pres-

sure and reverse rotation when it is stopped.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

ALIGNMENT

The alignment of the pump, air compressor and

engine is critical for trouble-free mechanical opera-

tion. See Section E, Securing Intermediate And

Drive Assembly To Engine in MAINTENANCE

AND REPAIR, for details.

AUTO-START

The standard pump is equipped with an auto-start

control system which allows the pump to start and

stop as the liquid level in the wet well or sump rises

and falls.

Refer to the information which follows for installa-

tion details for the liquid level sensing system pro-

vided with your pump.