Gorman-Rupp Pumps PA4A60C-C2.2T 1394774 and up User Manual

Page 41

OM-06168

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 19

gage the hardware (4 and 5) securing it to the fly

wheel.

Remove any leveling shims used under the casing

mounting feet. Tie and tag the shims for ease of

reassembly.

Move the pump end to a clean, well equipped shop

area for further disassembly.

(Figure 3)

Remove the belt (9). Remove the capscrews from

the center of the bushing (25). Reinstall the caps

crews in the tapped holes in the bushing and tight

en them in an alternating pattern until the bushing

is “jacked” out of the sprocket (24). Slide the bush

ing and sprocket off the shaft. Remove the key (31,

Figure 5).

Draining Oil From Seal Cavity

(Figure 5)

If any further disassembly is to be performed on the

pump, the seal oil cavity must be drained to pre

vent the oil in the seal cavity from escaping as the

pump casing is removed.

Position a clean container under the seal cavity

drain plug (15A). Remove the plug and drain the oil

from the seal cavity into the container. For shorter

drain time, remove the vented plug (10). Clean and

reinstall the drain plug and vent plug. Inspect the

oil for water, dirt or a cloudy condition which could

indicate seal failure.

Loosening Impeller

(Figure 5)

With the pump end separated from the engine,

wedge a block of wood between the vanes of the

impeller (1) and the pump casing (1, Figure 4) to

prevent rotation.

Install the shaft key (23) in the shaft keyway. Install

a lathe dog on the drive end of the shaft (24) with

the “V” notch positioned over the shaft key.

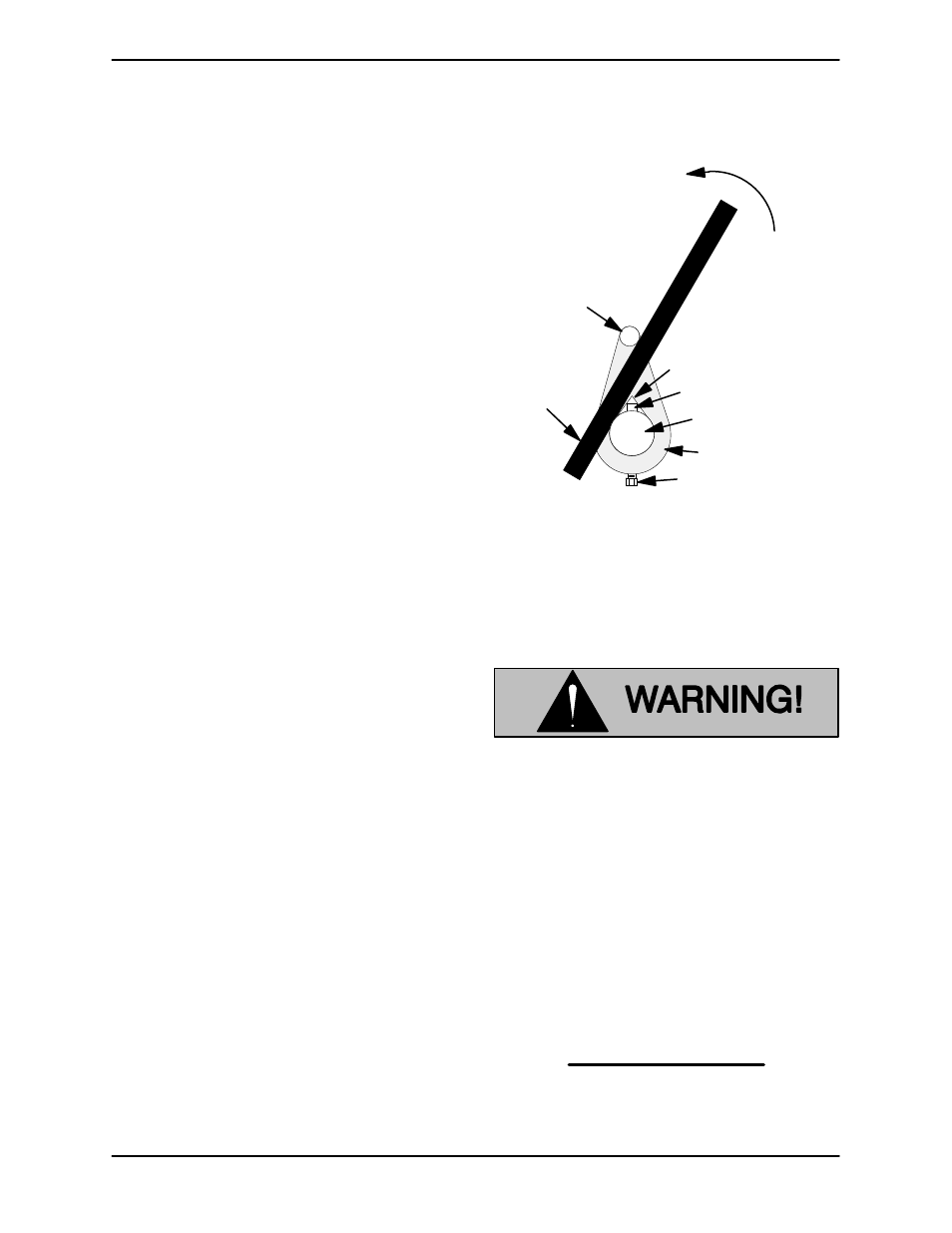

With the impeller rotation still blocked, see Figure

10 and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key

way. When the impeller breaks loose, remove the

lathe dog, key and wood block.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 10. Loosening Impeller

Pump Casing And Wear Plate Removal

(Figure 4)

Support the pump casing using a suitable hoist

and sling.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam

age to equipment. If slings or chains are

used to move the pump or components,

make sure that the load is balanced;

otherwise serious personal injury or

death could result. Suction and dis

charge hoses and piping must be re

moved from the pump before lifting.

NOTE

Drain the oil from the seal cavity before removing

the pump casing. See Draining Oil From Seal Cav

ity.

Remove the hardware (9 and 10) securing the

pump casing (1) to the rotating assembly (8). Pull

the pump casing straight away from the rotating