Gorman-Rupp Pumps PA6B60-6068H 1421583 and up User Manual

Page 42

PA SERIES

OM−06250

MAINTENANCE & REPAIR

PAGE E − 20

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the volute scroll.

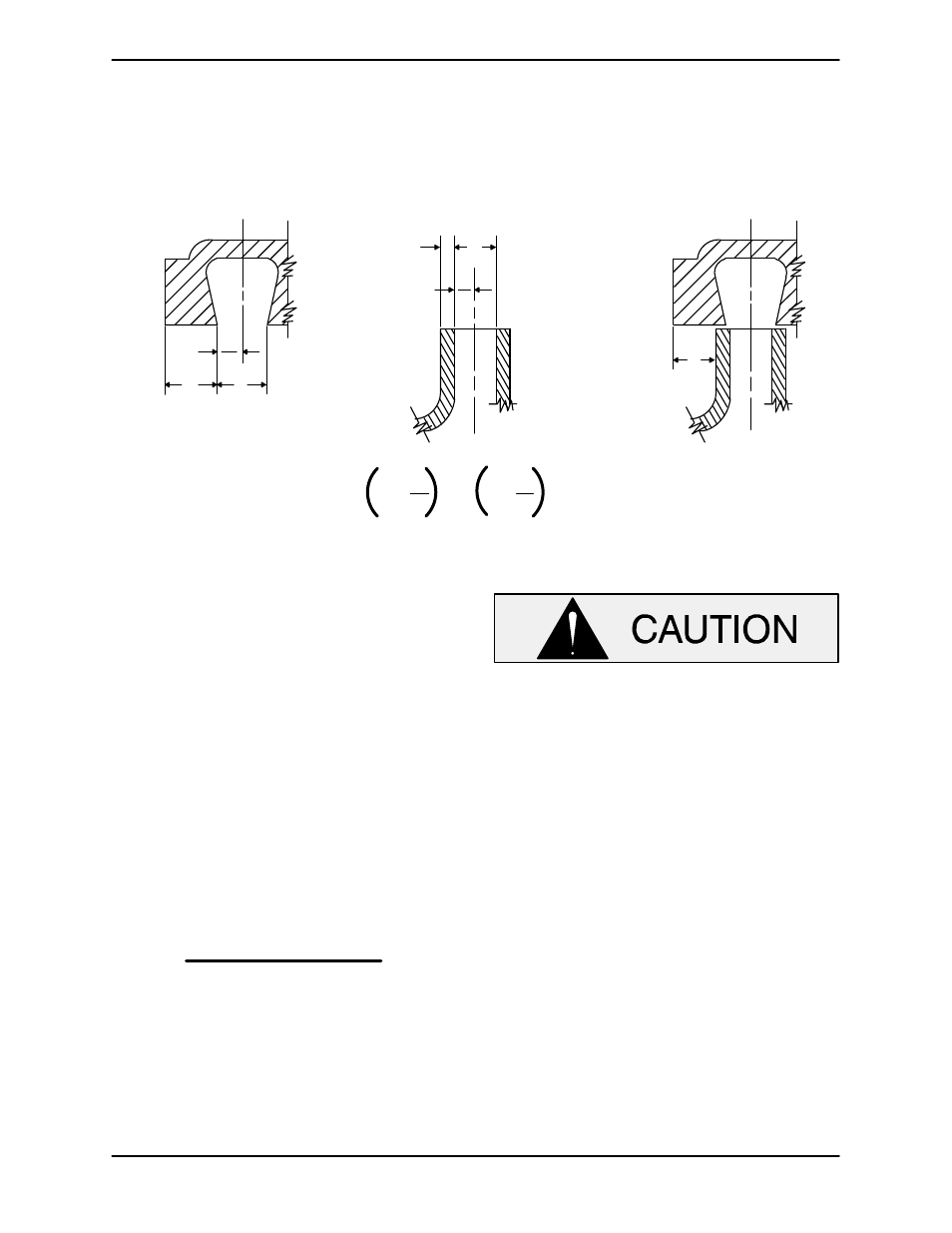

To verify the impeller positioning, measure the

pump casing and impeller as shown in Figure 10.

Use these measurements to calculate the required

impeller location (dimension E). Add or remove im-

peller adjusting shims until dimension E is ob-

tained.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

−

Figure 10. Centering Impeller Within Volute Scroll

Install the calculated thickness of impeller shims

(4). Install the impeller key (44) and slide the impel-

ler onto the shaft until fully seated. Make sure the

seal spring seats squarely over the step on the

back of the impeller.

Secure the shaft from rotating by reaching through

the discharge port and tightly wedging a soft-metal

bar between the vanes of the impeller. Install the O-

ring (41) in the groove in the impeller nut (42) and

secure the impeller with the impeller nut and fillister

head screw (40).

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping bind-

ing before further reassembly.

Suction Head Installation

(Figure 4)

If removed at disassembly, press the wear ring (39)

into the suction head (38) until it seats squarely

against the bore shoulder.

The wear ring must seat squarely in the

suction head; otherwise binding and/or ex-

cessive wear will result.

Install the suction head gasket (37) on the casing

studs (33) and secure the suction head to the

pump casing with the nuts (34). Make sure the

jacking screws (43) do not interfere with the suc-

tion head seating.

Discharge Check Valve Assembly And

Installation

(Figure 3)

If the discharge check valve (7) was disassembled

to replace the flapper or cover O-ring, position the

flapper in the valve body and check to ensure free

movement.

Install the valve cover O-ring and secure the cover

to the body with the previously removed hardware.

Apply a small amount of light grease to the dis-

charge flange gasket (9) to hold it in place and po-