Gorman-Rupp Pumps PA6B60-6068H 1421583 and up User Manual

Page 41

OM−06250

PA SERIES

MAINTENANCE & REPAIR

PAGE E − 19

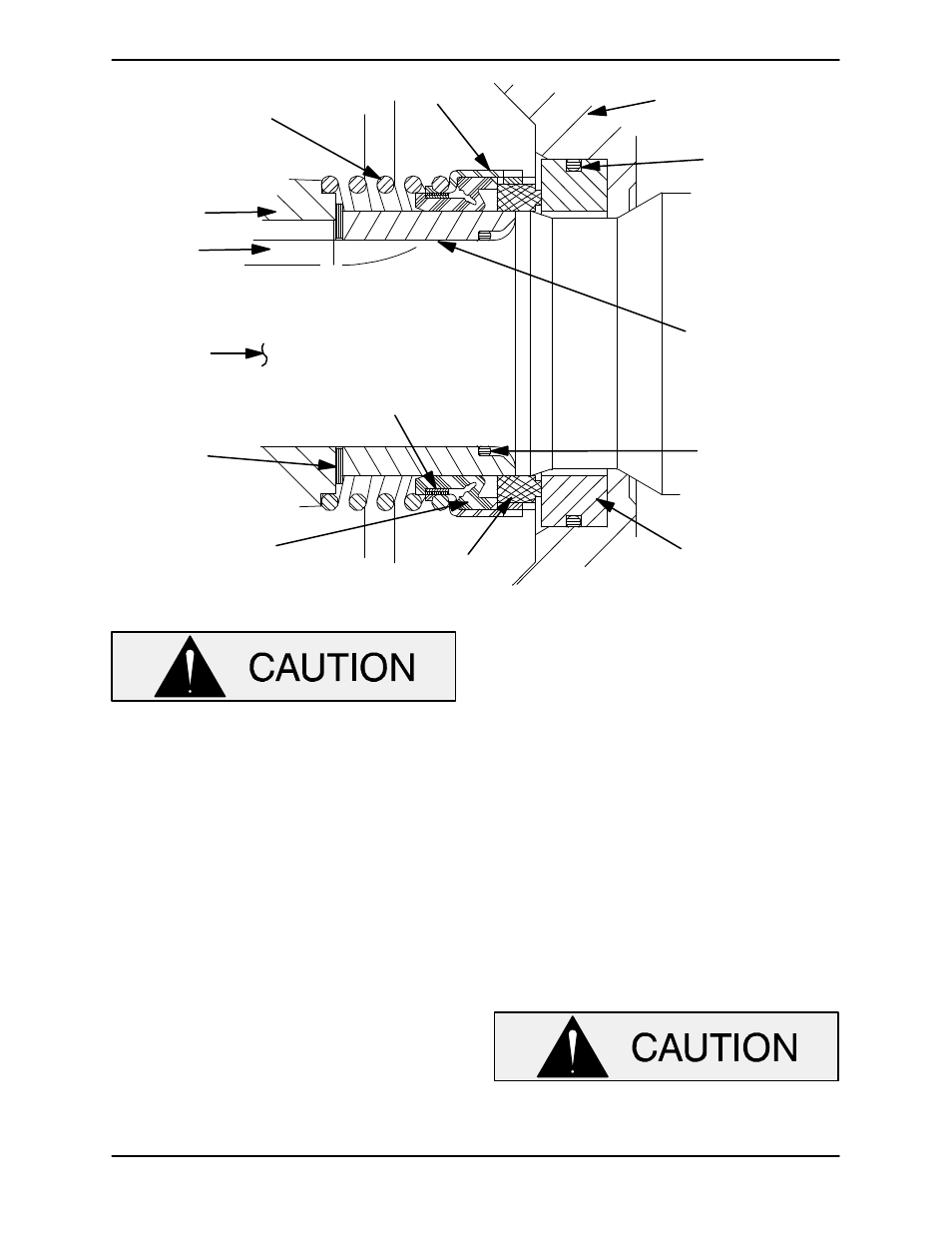

O-RING

IMPELLER

STATIONARY

SEAT

ROTATING ELEMENT

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

SHAFT

DRIVE BAND

PUMP CASING

SHAFT SLEEVE

SHAFT SLEEVE

O-RING

IMPELLER

KEY

Figure 9. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Inspect the pump casing and impeller shaft for

burrs or sharp corners and remove any that exist.

With the stationary seat O-ring lubricated and

installed in the stationary seat, press the stationary

seat into the pump casing until it seats squarely

against the bore shoulder. A push tube cut from a

length of plastic pipe would aid this installation.

The O.D. of the pipe should be approximately the

same diameter as the O.D. of the seal spring.

Lubricate the shaft sleeve O-ring (6) and slide it

onto the shaft until it seats against the shaft shoul-

der.

Use even pressure to carefully press this rotating

portion of the seal onto the lubricated sleeve (5) un-

til the seal face is just flush with the chamfered end

of the sleeve.

Slide the assembled shaft sleeve and rotating por-

tion of the seal onto the shaft until the seal faces

contact. Continue to push the sleeve through the

seal until it seats squarely against the shaft shoul-

der.

Install the seal spring.

Impeller Installation

(Figure 4)

If the balance ring (38) was removed, press the re-

placement ring into the pump casing as described

in Pump Casing Installation.

The balance ring must seat squarely in the

suction head; otherwise binding and/or ex-

cessive wear will result.