Gorman-Rupp Pumps PA6C60C-F4L 1318119 thru 1504810 User Manual

Page 46

PA SERIES

OM-05768

MAINTENANCE & REPAIR

PAGE E - 24

Impeller Installation And Adjustment

(Figure 5)

Inspect the impeller (1) and replace it if cracked or

badly worn.

The shaft and impeller threads must be

completely clean before reinstalling the im

peller. Even the slightest amount of dirt on

the threads can cause the impeller to seize

to the shaft, making future removal difficult

or impossible without damage to the im

peller or shaft.

Install the same thickness of impeller adjusting

shims (30) as previously removed and screw the

impeller onto the shaft until tight.

NOTE

At the slightest sign of binding, immediately back

the impeller off, and check the threads for dirt. Do

not try to force the impeller onto the shaft.

A clearance of .025 to .040 inch (0,64 to 1,02 mm)

between the impeller and the seal plate is neces

sary for maximum pump efficiency. Measure this

clearance, and add or remove impeller adjusting

shims as required.

Apply `Never‐Seeze' or equivalent compound to

the threads of the capscrew (21). Secure the impel

ler to the shaft with the impeller washer (22) and

capscrew (21 and 22). Torque the impeller caps

crew to 90 ft. lbs. (12,4 m. kg.).

Pump Casing Installation

(Figure 4)

Lubricate the O‐rings (37 and 38) with light grease,

and install them in the grooves in the bearing hous

ing and seal plate. Use a suitable hoist and sling to

slide the pump casing (1) over the rotating assem

bly.

Install the same thickness of adjusting shims (14)

as previously removed, and secure the rotating as

sembly to the pump casing with the hardware (12

and 13).

Wear Plate And Back Cover Plate Installation

And Adjustment

(Figures 4 and 11)

If the wear plate (5) was removed for replacement,

carefully center it on the back cover (18) and se

cure it with the hardware (3 and 4).

Lubricate the O‐rings (6 and 17) with light grease

and install them in the grooves in the wear plate

and back cover.

Clearance between the impeller and wear plate is

adjusted using four hand knobs (22) and locking

collars (19). There are 18 detents on the I.D. of

each locking collar. Indexing the collars one detent

on the adjusting screws represents approximately

.005 inch (0,13 mm) of wear plate clearance. The

recommended clearance between the wear plate

and the impeller is .010 to .020 inch (0,25 to 0,50

mm).

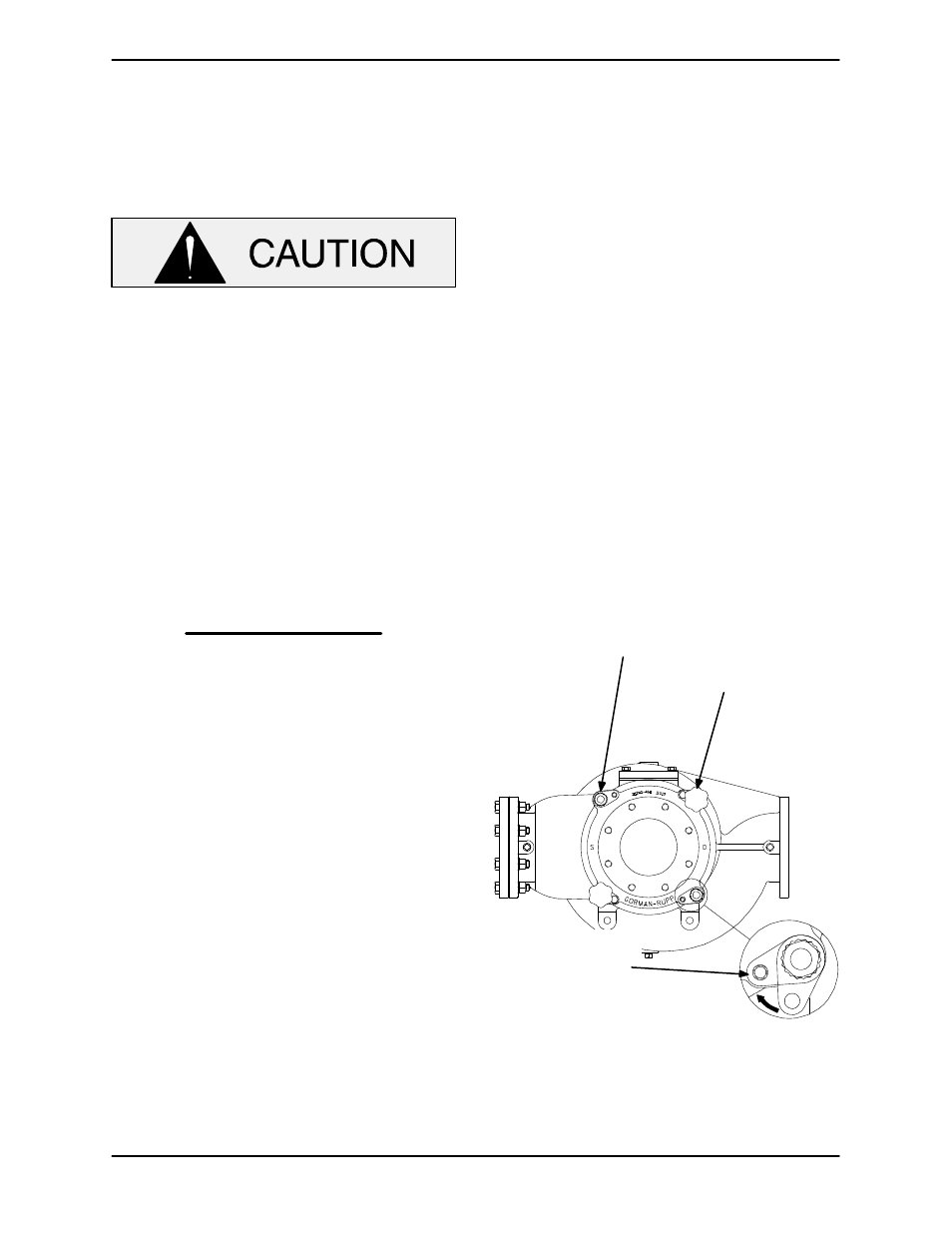

USE TWO

OPPOSING

HAND NUTS

TO PRESS

BACK COVER

INTO PUMP

CASING

USE TWO REMAINING

ADJUSTING SCREWS

AND LOCKING COL

LARS TO SET FACE

CLEARANCE

TURN INDEX COLLARS

3 DETENTS COUNTER‐

CLOCKWISE, THEN

TURN CLOCKWISE UN

TIL SCREW HOLES

ALIGN

Figure 11. Installing and Adjusting Back Cover

Screw the four adjusting screws (20) into the

tapped holes in the back cover plate until they are

just flush with the machined surface on the back

side of the cover plate.