Gorman-Rupp Pumps PAH6B60-6068H IT4 1529202 and up User Manual

Page 47

PAH SERIES

OM-06602

MAINTENANCE & REPAIR

PAGE E - 24

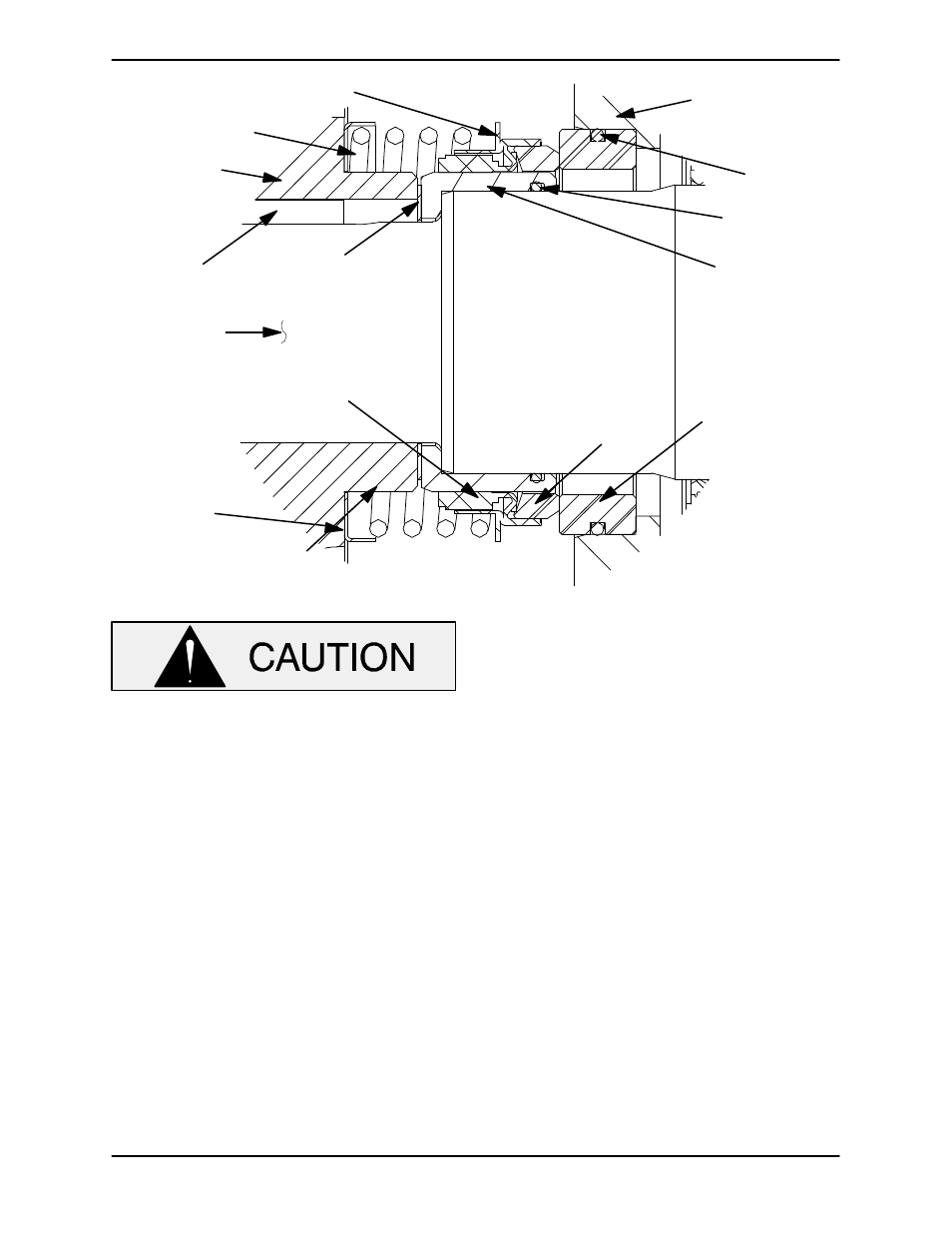

SEAL PLATE

O‐RING

IMPELLER

SHAFT

STATIONARY

ELEMENT

ROTATING

ELEMENT

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

SHAFT

SLEEVE

SLEEVE

O‐RING

SPRING

CENTERING

WASHER

SHAFT

KEY

Figure 10. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

If the seal plate was removed, install the seal plate

gasket (14). Position the seal plate over the shaft

and secure it to the bearing housing with the hard

ware (15 and 16).

Press the stationary element and its O‐ring into the

seal plate until fully seated in the seal plate bore. A

push tube cut from a length of plastic pipe would

aid this process. The I.D. of the tube should be

slightly larger than the O.D. of the shaft sleeve (7).

Install the shaft sleeve O‐ring (8) in the groove in

the I.D. of the sleeve. Lubricate the O‐ring and the

O.D. of the shaft sleeve with “P-80

R

Emulsion” or

water. Do not use oil or any substitute lubricant

other than water.

Slide the rotating subassembly (consisting of the

rotating element, retainer and bellows) onto the

sleeve until the rotating element is just flush with

the chamfered end of the sleeve. Slide the shaft

sleeve and rotating subassembly onto the shaft

until the seal faces contact and the shaft sleeve

seats against the shoulder on the impeller shaft.

Install the seal spring and spring centering washer.

Lubricate the seal assembly as indicated in

LUBRICATION, after the impeller has been in

stalled.

Impeller Installation And Adjustment

(Figure 6)

Inspect the impeller (1) and replace it if cracked or

badly worn.

Install the same thickness of adjusting shims (5) as

previously installed. Install the impeller key (26) in

the shaft keyway. Align the keyway in the impeller

with the shaft key and press the impeller onto the

shaft until fully seated.

A clearance of .025 to .040 inch (0,64 to 1,02 mm)

between the impeller and the seal plate is neces

sary for maximum pump efficiency. Measure this

clearance and add or remove impeller adjusting

shims as required.