Gorman-Rupp Pumps VGH2 1/2D31-B 1379872 thru 1208720 User Manual

Page 11

OM−06122

VGH SERIES

PAGE B − 4

INSTALLATION

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si-

phon breaker is used in the line. Otherwise, a si-

phoning action causing damage to the pump

could result.

Valves

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be in-

stalled in the discharge line to protect the pump

from excessive shock pressure and reverse rota-

tion when it is stopped.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

LUBRICATION

Bearings

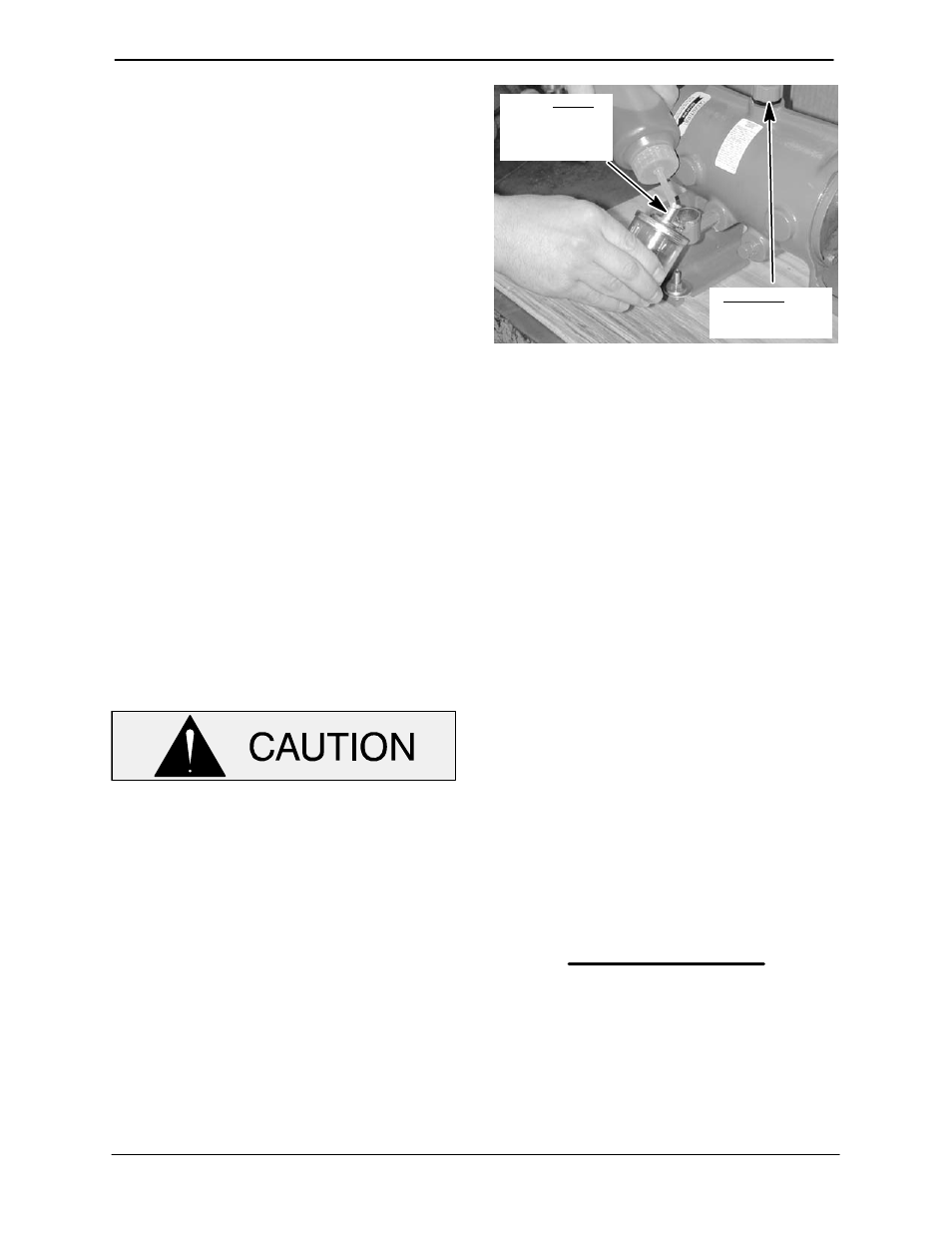

The bearing housing was not lubricated when

shipped from the factory. To lubricate the bearing

cavity, fill the constant level oiler as shown in Figure

2, then close the oiler and allow the oil to drain into

the bearing cavity. Repeat this procedure until oil

no longer drains from the constant level oiler.

FILL ONLY

THROUGH

CONSTANT

LEVEL OILER

DO NOT FILL

THROUGH

VENT PLUG

Figure 2. Lubricating Bearing Cavity

Do not fill the bearing cavity through the vent plug

in the top of the housing. This will result in over-fill-

ing, and can cause leakage, excessive heat build

up and/or premature bearing failure.

Check the oil level regularly through the constant

level oiler and add oil as required.

Seal Assembly

The seal assembly is lubricated by the medium be-

ing pumped and no additional lubrication is re-

quired.

ALIGNMENT

The alignment of the pump and its power source is

critical for trouble-free mechanical operation. In

either a flexible coupling or V-belt driven system,

the driver and pump must be mounted so that their

shafts are aligned with and parallel to each other. It

is imperative that alignment be checked after the

pump and piping are installed, and before opera-

tion.

NOTE

Check Rotation, Section C, before final alignment

of the pump.

When mounted at the Gorman-Rupp factory, driver

and pump are aligned before shipment. Misalign-

ment will occur in transit and handling. Pumps

must be checked and realigned before operation.

Before checking alignment, tighten the foundation

bolts. The pump casing feet and/or pedestal feet,

and the driver mounting bolts should also be tightly

secured.