Gorman-Rupp Pumps 54J2-B 1424552 and up User Manual

Page 33

OM−01337

50 SERIES

MAINTENANCE & REPAIR

PAGE E − 11

NOTE

The white reflector in the sight gauge must be posi-

tioned horizontally to provide proper drainage.

Under normal conditions, drain the pedestal once

each year and refill with approximately 14 ounces

(414 ml) of clean oil. Change the oil more fre-

quently if the pump is operated continuously or in-

stalled in an environment with rapid temperature

change.

Monitor the condition of the bearing lubri-

cant regularly for evidence of rust or mois-

ture condensation. This is especially im-

portant in areas where variable hot and

cold temperatures are common.

For cold weather operation, consult the factory or a

lubricant supplier for the recommended grade of

oil.

Seal Assembly

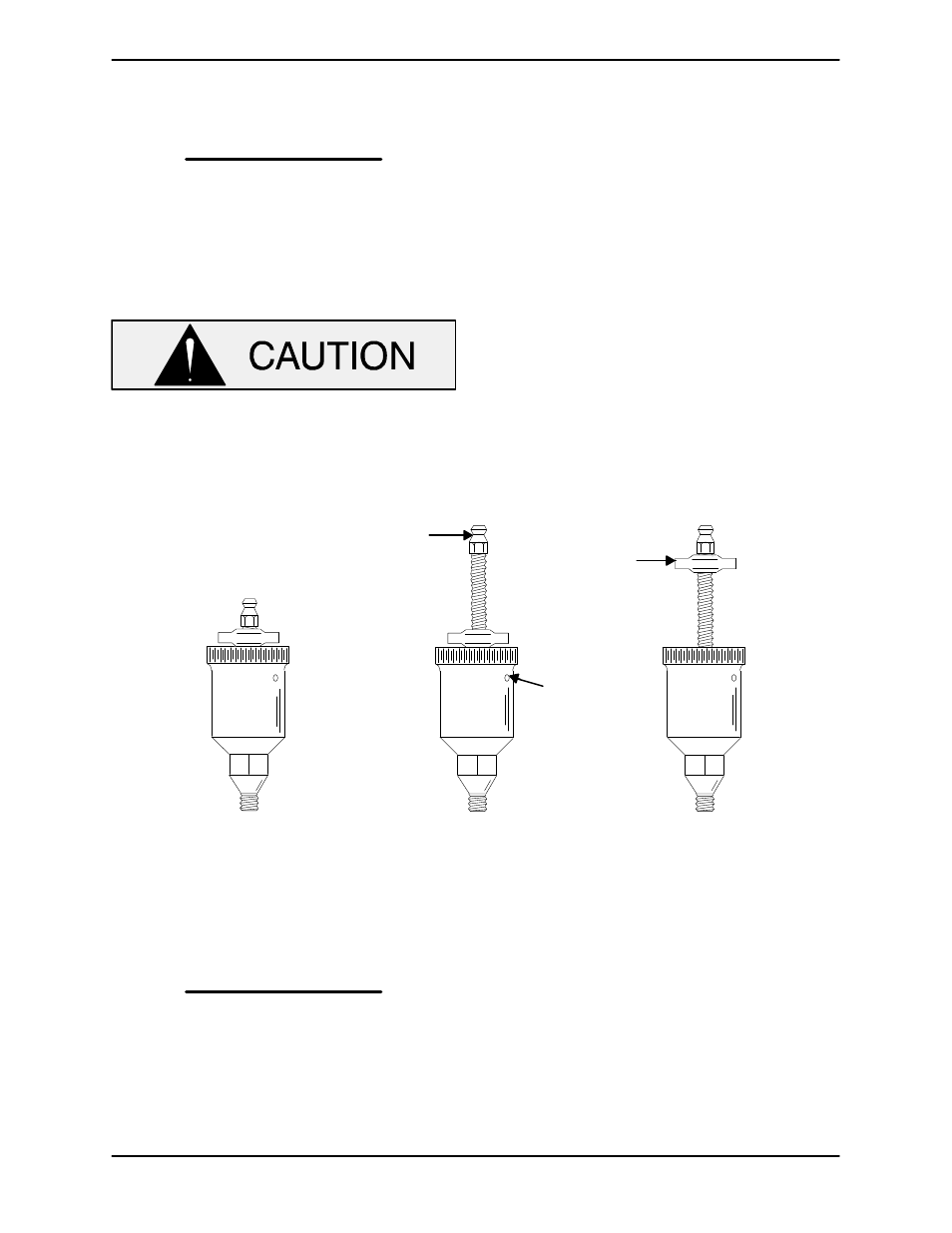

Fill the grease cup (14) through the grease fitting

with No. 2 lithium base grease until grease es-

capes from the relief hole. Turn the grease cup arm

counterclockwise until it is at the top of the stem;

this will release the spring to apply grease to the

seal (see Figure 6).

GREASE

FITTING

CROSS

ARM

POSITION

WHEN

EMPTY

POSITION

FOR

FILLING

POSITION

WHEN

IN USE

RELIEF

HOLE

Figure 6. Automatic Lubricating Grease Cup

NOTE

Some smoking and leakage may occur after instal-

ling a new seal assembly. This should stop after the

pump has run a while and the lapped seal faces

have seated in.

Power Source

Consult the literature supplied with the power

source, or contact your local power source repre-

sentative.