Gorman-Rupp Pumps 54J2-B 1424552 and up User Manual

Page 31

OM−01337

50 SERIES

MAINTENANCE & REPAIR

PAGE E − 9

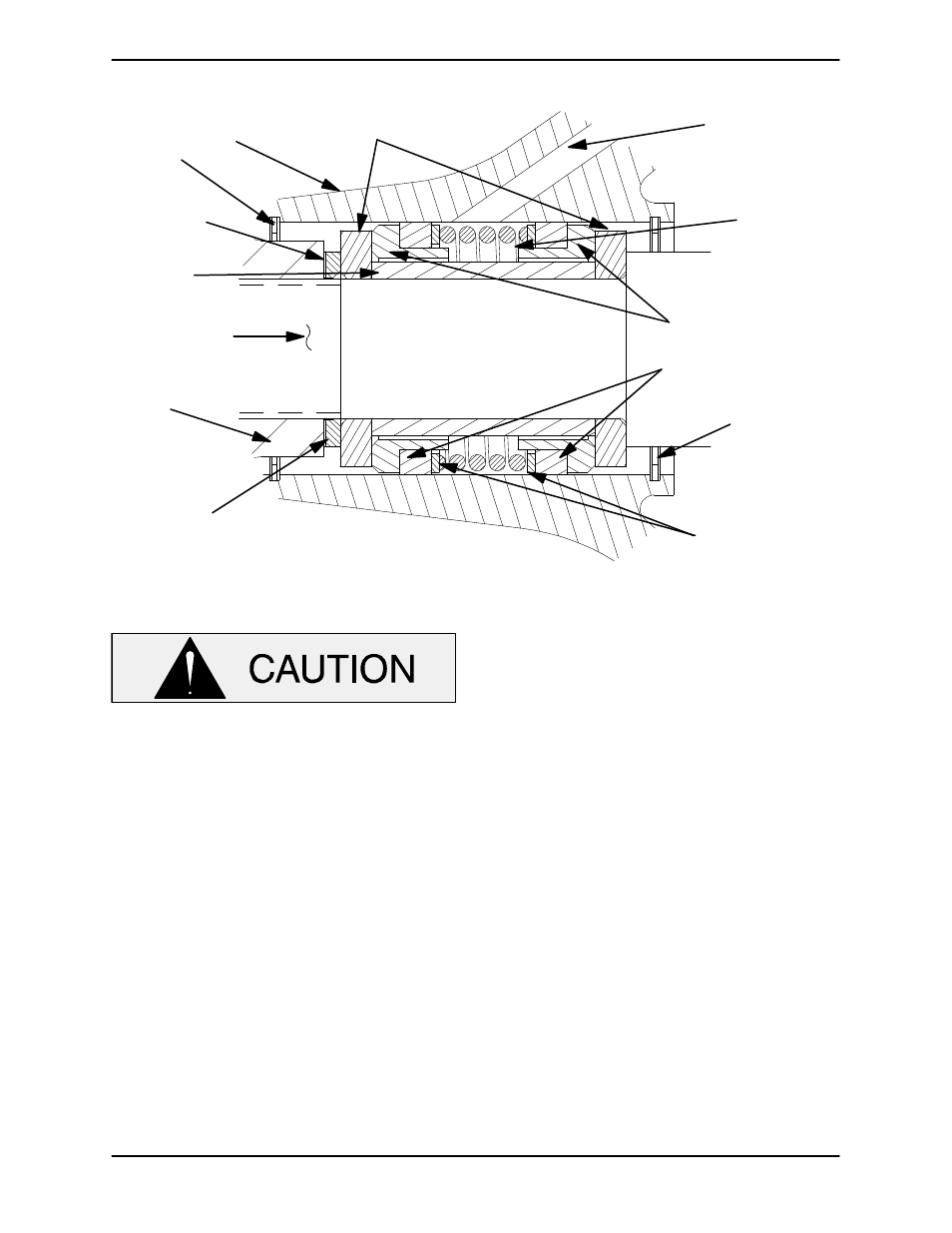

SEAL

HOUSING

LUBRICATION

CHANNEL

ROTATING

ELEMENTS

STATIONARY

SEATS

PACKING

RINGS

SPRING

SEAL

WASHER

IMPELLER

SHIMS

IMPELLER

SPACER

SLEEVE

PACKING

WASHERS

IMPELLER

SHAFT

SNAP

RING

SNAP

RING

Figure 4. GS1250 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Install the inboard snap ring (43) in the groove in

the I.D. of the seal housing (7). Make sure the lu-

brication channel in the seal housing alignes with

the opening in the bearing housing and secure the

seal housing to the pedestal with the hardware (10

and 11).

Lubricate the I.D. of the seal housing with light oil.

Position the inboard rotating element on the shaft

with the chamfer facing the shaft shoulder. Slide

the element onto the shaft until fully seated against

the shaft shoulder.

Subassemble the inboard stationary seat, packing

ring and spring washer, and press the subassem-

bly into the lubricated seal liner. A push tube cut

from a length of plastic pipe would aid this installa-

tion. The O.D. of the tuve should be slightly smaller

than the I.D. of the seal liner.

Install the spacer sleeve and spring.

Subassemble the outboard stationary seat, pack-

ing ring and spring washer. Press this subassem-

bly into the seal liner.

Install the outboard rotating element with the

chamfered side facing the impeller end of the shaft.

Install the seal washer (45) with the chamfered side

facing the outboard rotating element.

Install the automatic grease cup (14) in the bearing

housing. After the impeller is installed, lubricate the

seal assembly as indicated in LUBRICATION.

Impeller And Wear Ring Installation

If the wear ring (6) was removed for replacement,

remove the jacking screws, align the mounting

holes, and press the wear ring into the pump cas-

ing until fully seated. Apply ‘Never-Seez’ or equiva-

lent compound to the hardware (4 and 5) and se-

cure the wear ring to the pump casing.