Gorman-Rupp Pumps T8A65S-B /F,/FM User Manual

Page 30

OM-05498

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 8

they are heavy enough for safe use and will not

damage the pump.

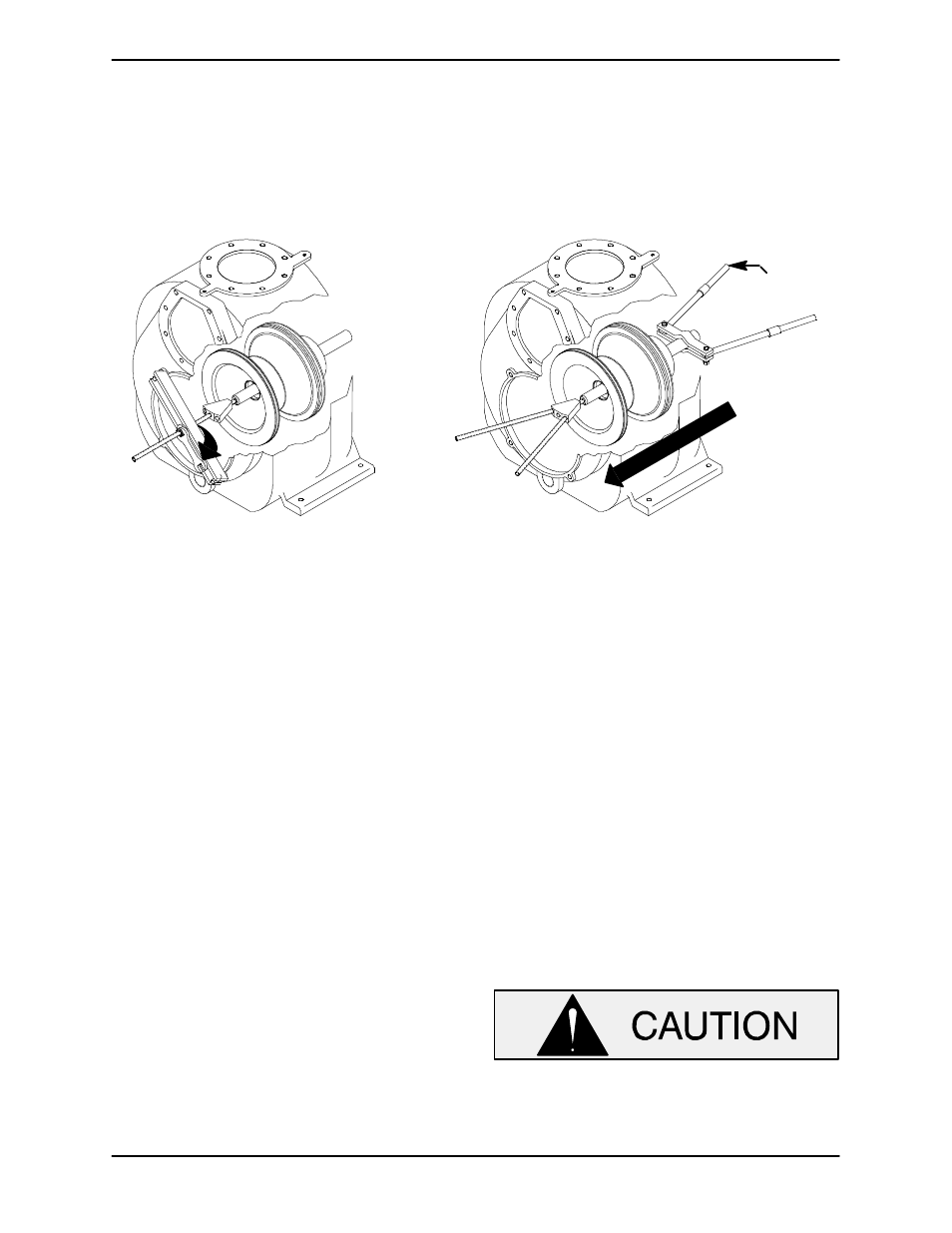

After the rotating assembly is loosened, screw a

5/8-18 UNF X 16‐inch long threaded rod into the

impeller shaft. Support the drive end with another

set of handles, or a length of pipe (1-13/16 inch

[46 mm] minimum I.D.), and slide the complete ro

tating assembly through the back cover opening

(see Figure 4). Move the rotating assembly to a

clean work area before proceeding with disassem

bly.

ADD PIPE

AS REQUIRED

Figure 4. Rotating Assembly Removal

Remove the seal plate and bearing housing O‐

rings (20 and 21).

Impeller Removal

(Figure 2)

With the rotating assembly removed from the

pump casing, unscrew the impeller from the shaft.

Use caution when unscrewing the impeller; ten

sion on the seal spring will be released as the im

peller is removed. Inspect the impeller and replace

if cracked or badly worn.

Remove the impeller adjusting shims (31); tie and

tag the shims, or measure and record their thick

ness for ease of reassembly.

Seal Removal

(Figure 2)

Slide the shaft sleeve and rotating portion of the

seal off the shaft as a unit.

Use a pair of stiff wires with hooked ends to remove

the stationary element and seat.

An alternate method of removing the stationary

seal components is to remove the hardware (5 and

6) and separate the seal plate (3) and gasket (4)

from the bearing housing (7). Position the seal

plate on a flat surface with the impeller side down.

Use a wooden dowel or other suitable tool to press

on the back side of the stationary seat until the

seat, O‐rings, and stationary element can be re

moved.

If no further disassembly is required, refer to Seal

Installation.

Shaft and Bearing Removal and Disassembly

(Figure 2)

When the pump is properly operated and main

tained, the bearing housing should not require dis

assembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly‐

equipped shop by qualified personnel.