Gorman-Rupp Pumps T6A3S-B /F,/FM,/WW,/WWS User Manual

Page 34

OM-05144

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 12

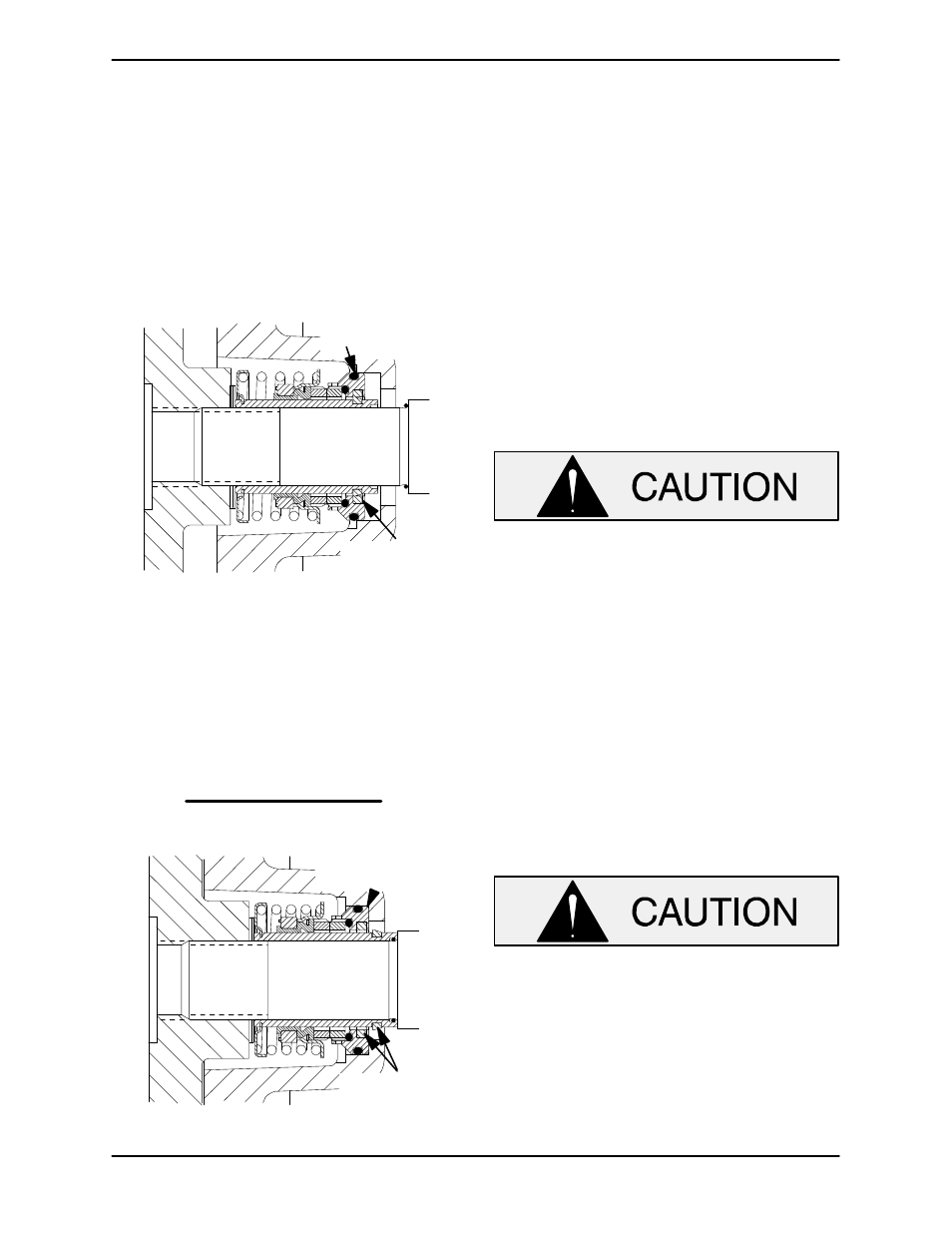

Lubricate the external stationary seat O‐ring with

light oil. Slide the seal assembly onto the shaft until

the external stationary seat O‐ring engages the

bore in the seal plate.

Clean and inspect the impeller as described in Im

peller Installation and Adjustment. Install the full

set of impeller shims (30) provided with the seal,

and screw the impeller onto the shaft until it is

seated against the seal (see Figure 6).

O‐RING ENGAGED

WITH SEAL PLATE

BORE

SHEAR RING

(UNSHEARED)

Figure 6. Seal Partially Installed

Continue to screw the impeller onto the shaft. This

will press the stationary seat into the seal plate

bore.

NOTE

A firm resistance will be felt as the impeller presses

the stationary seat into the seal plate bore.

STATIONARY SEAT

FULLY SEATED IN

SEAL PLATE BORE

SHEAR RING

(SHEARED)

Figure 7. Seal Fully Installed

As the stationary seat becomes fully seated, the

seal spring compresses, and the shaft sleeve will

break the nylon shear ring. This allows the sleeve

to slide down the shaft until seated against the

shaft shoulder. Continue to screw the impeller onto

the shaft until the impeller, shims, and sleeve are

fully seated against the shaft shoulder (see Figure

7).

Measure the impeller‐to‐seal plate clearance, and

remove impeller adjusting shims to obtain the

proper clearance as described in Impeller Instal

lation and Adjustment.

If necessary to reuse an old seal in an emer

gency, carefully separate the rotating and station

ary seal faces from the bellows retainer and sta

tionary seat.

A new seal assembly should be installed

any time the old seal is removed from the

pump. Wear patterns on the finished faces

cannot be realigned during reassembly.

Reusing an old seal could result in prema

ture failure.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non‐oil based solvent and a clean, lint‐free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Carefully wash all metallic parts in fresh cleaning

solvent and allow to dry thoroughly.

Do not attempt to separate the rotating

portion of the seal from the shaft sleeve

when reusing an old seal. The rubber bel

lows will adhere to the sleeve during use,

and attempting to separate them could

damage the bellows.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak

age. Inspect the integral shaft sleeve for nicks or