Gorman-Rupp Pumps T3A61S-B /F,/FM User Manual

Page 13

OM-05264

SUPER T SERIES

PAGE B - 6

INSTALLATION

pump can cause parts being disen

gaged to be ejected with great force. Af

ter the pump completely cools, drain the

liquid from the pump by removing the

casing drain plug. Use caution when re

moving the plug to prevent injury to per

sonnel from hot liquid.

AUTOMATIC AIR RELEASE VALVE

When properly installed and correctly adjusted to

the specific hydraulic operating conditions of the

application, the Gorman‐Rupp Automatic Air Re

lease Valve will permit air to escape through the by

pass line, and then close automatically when the

pump is fully primed and pumping at full capacity.

Theory of Operation

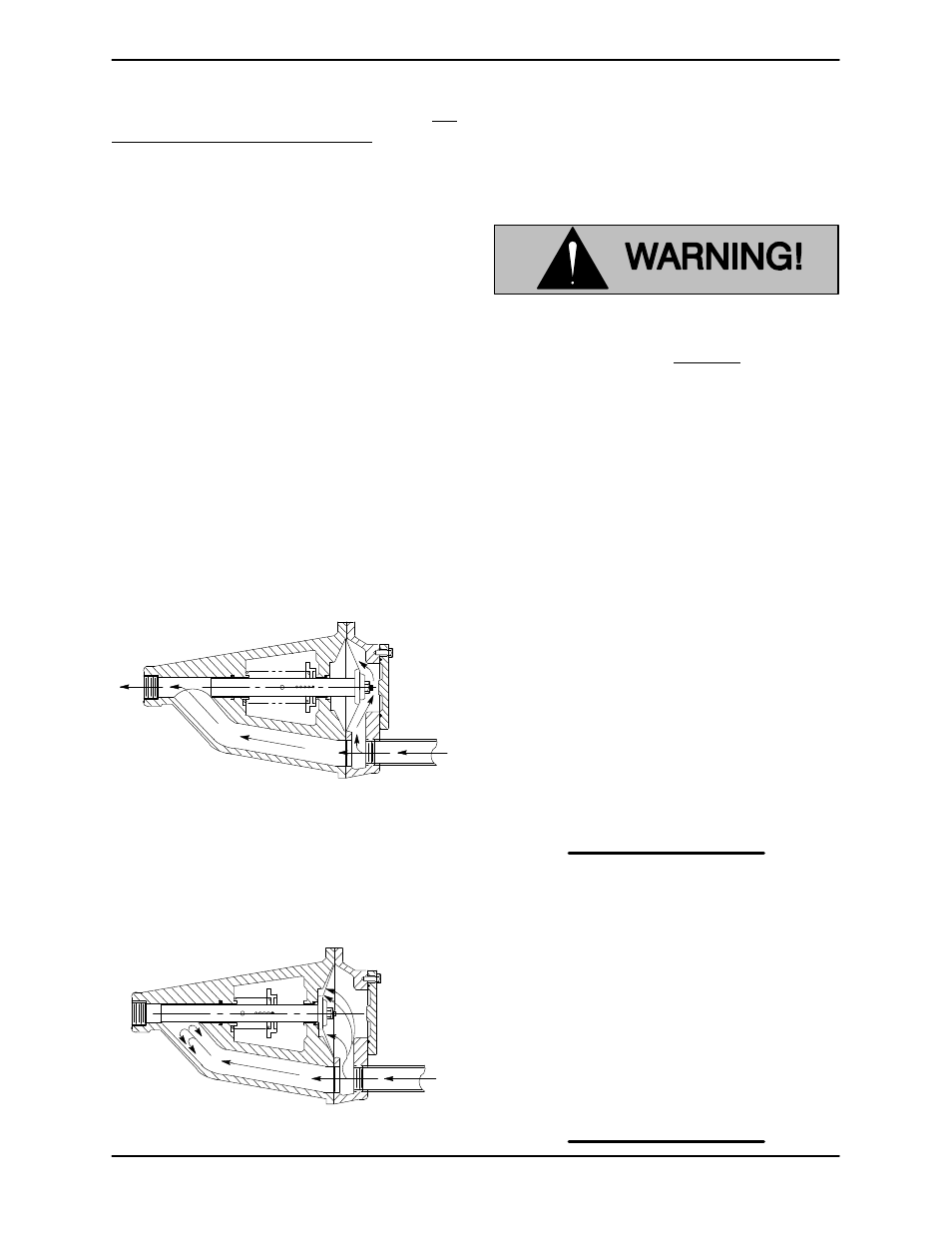

Figures 3 and 4 show a cross‐sectional view of the

Automatic Air Release Valve, and a corresponding

description of operation.

Й

Й

Й

Figure 3. Valve in Open Position

During the priming cycle, air from the pump casing

flows through the bypass line, and passes through

the Air Release Valve to the wet well (Figure 3).

Й

Й

Й

Й

Й

Figure 4. Valve in Closed Position

When the pump is fully primed, pressure resulting

from flow against the valve diaphragm com

presses the spring and closes the valve (Figure 4).

The valve will remain closed, reducing the bypass

of liquid to 1 to 5 gallons (3.8 to 19 liters) per min

ute, until the pump loses its prime or stops.

Some leakage (1 to 5 gallons [3.8 to 19

liters] per minute) will occur when the

valve is fully closed. Be sure the bypass

line is directed back to the wet well or

tank to prevent hazardous spills.

When the pump shuts down, the spring returns the

diaphragm to its original position. Any solids that

may have accumulated in the diaphragm chamber

settle to the bottom and are flushed out during the

next priming cycle.

NOTE

The valve will remain open if the pump does not

reach its designed capacity or head. Valve closing

pressure is dependent upon the discharge head of

the pump at full capacity. The range of the valve

closing pressure is established by the tension rate

of the spring as ordered from the factory. Valve clos

ing pressure can be further adjusted to the exact

system requirements by moving the spring retain

ing pin up or down the plunger rod to increase or

decrease tension on the spring. Contact your Gor

man‐Rupp distributor or the Gorman‐Rupp Com

pany for information about an Automatic Air Re

lease Valve for your specific application.

Air Release Valve Installation

The Automatic Air Release Valve must be inde

pendently mounted in a horizontal position and

connected to the discharge line of the self‐priming

centrifugal pump (see Figure 5).

NOTE

If the Air Release Valve is to be installed on a staged

pump application, position the air release valve as

close as possible to the discharge check valve.