Gorman-Rupp Pumps 03H1-B 710816 and up User Manual

Page 27

0 SERIES

OM-01192

MAINTENANCE & REPAIR

PAGE E - 8

a drop of light lubricating oil on the finished faces.

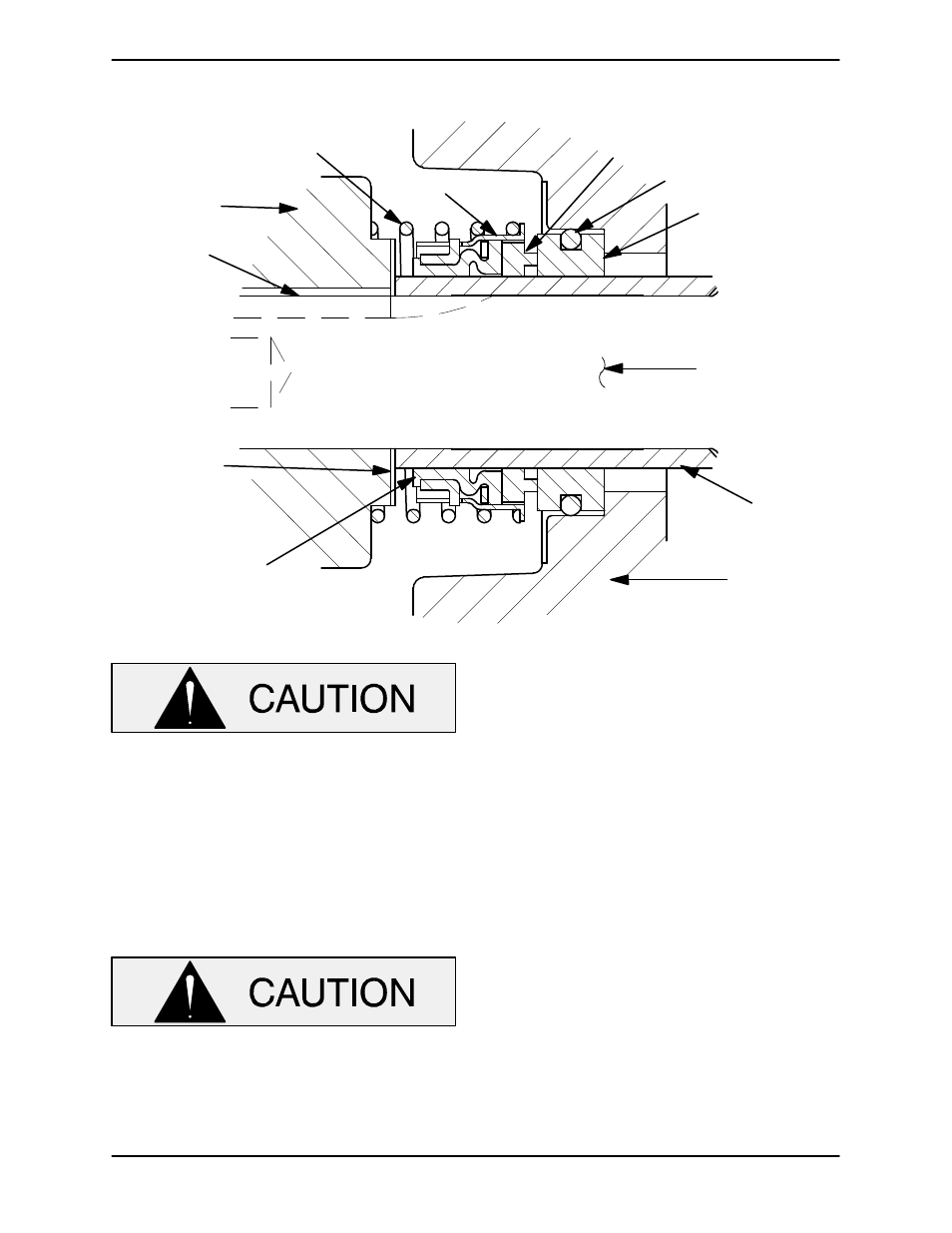

Assemble the seal as follows, (see Figure 2).

IMPELLER

SHAFT

SEAL

PLATE

ROTATING

ELEMENT

RETAINER

SPRING

IMPELLER

ADJUSTING

SHIMS

IMPELLER

BELLOWS

SHAFT

SLEEVE

O‐RING

STATIONARY

ELEMENT

IMPELLER

KEY

Figure 2. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lay the seal plate (7) on a flat surface with the im

peller side facing up.

If removed at disassembly, press the replacement

wear ring (7) into the seal plate until it seats square

ly against the shoulder bore.

The wear ring must seat squarely in the

seal plate bore or binding and/or exces

sive wear will result.

Subassemble the O‐ring onto the stationary ele

ment and use even pressure to press this subas

sembly into the seal plate until it seats squarely

against the shoulder bore.

Carefully slide the assembled seal plate and sta

tionary seal element over the shaft. Use caution not

to nick or damage the stationary seat. Use two

capscrews and nuts (not supplied) to temporarily

secure the seal plate to the pedestal.

Subassemble the rotating element into the retainer

and bellows. Lubricate the I.D. of the bellows with

water, and slide this subassembly over the shaft

sleeve until the seal face is just flush with the under

cut end of the sleeve.

To prevent damaging the shaft sleeve O‐ring (11)

on the shaft threads, stretch the O‐ring over a piece

of tubing 7/8 inch I.D. x 1 inch O.D. x 2‐inches long

(22 mm x 25 mm x 51 mm). Slide the tube over the

shaft threads, then slide the O‐ring off the tube and

onto the shaft. Remove the tube, and continue to

slide the O‐ring down the shaft until it seats against

the shaft shoulder.

Slide the assembled shaft sleeve and rotating por

tion of the seal and onto the shaft until the polished