Gorman-Rupp Pumps 04B3-F4L 1316966 and up User Manual

Page 30

0 SERIES

OM-01216

MAINTENANCE & REPAIR

PAGE E - 10

NOTE

If a hot oil bath is used to heat the bearing, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor

oughly filtered.

The bearing may be heated to ease installation. An

induction heater, hot oil bath, electric oven, or hot

plate may be used to heat the bearing. Bearings

should never be heated with a direct flame or di

rectly on a hot plate.

NOTE

Position the bearing on the shaft as indicated in Fig

ure 4.

Heat the bearing to a uniform temperature no

higher than 250

_F (120_C), and slide the bearing

onto the shaft until fully seated against the bearing

spacer. This should be done quickly, in one con

tinuous motion, to prevent the bearing from cool

ing and sticking on the shaft.

Use caution when handling hot bear

ings to prevent burns.

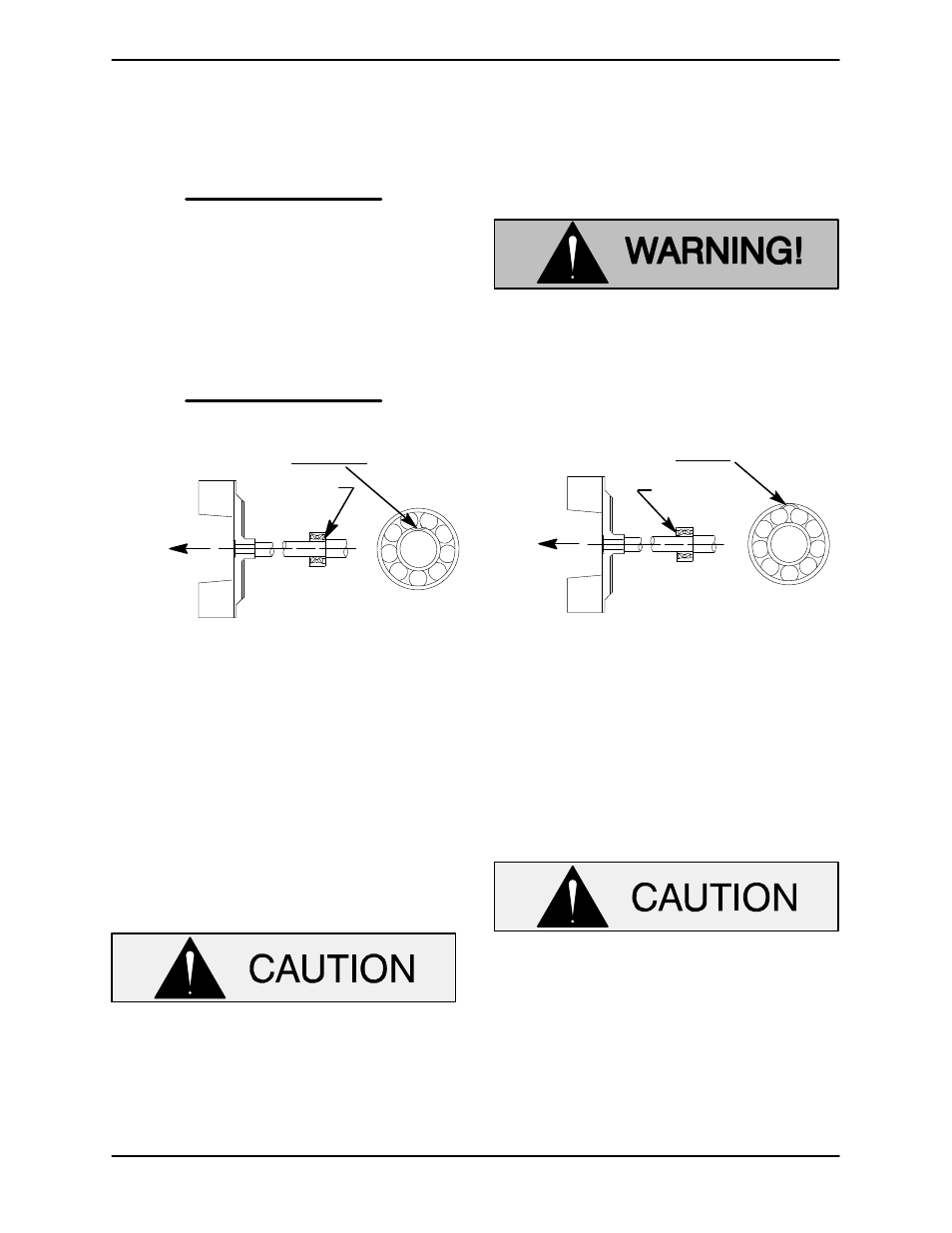

INSTALLATION OF FEDERAL MOGAL 5300W

OR NTN 3300 SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

INSTALLATION OF MRC/SKF 5300M, 5300E OR

TIMKEN 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

LOADING

DIRECTION OF

THRUST

BALL LOADING

GROOVE POSITIONED

AWAY FROM IMPELLER

GROOVE

DIRECTION OF

THRUST

LOADING

BALL LOADING

GROOVE POSITIONED

TOWARD IMPELLER

GROOVE

Figure 4. Bearing Positioning

After the bearing has been installed and allowed to

cool, check to ensure that it has not moved in

shrinking. If movement has occurred, use a suit

able sized sleeve and a press to reposition the

bearing.

If heating the bearing is not practical, use a suitable

sized sleeve and an arbor (or hydraulic) press to in

stall the bearing on the shaft.

When installing the bearing on the shaft,

never press or hit against the outer race,

balls, or ball cage. Press only on the inner

race.

Pack the bearing by hand with No. 0 lithium based

grease until the bearing balls are thoroughly lubri

cated. Secure the bearing on the shaft with the in

board bearing retaining ring (24).

Slide the shaft and assembled bearing into the in

termediate bore from the drive end until the bear

ing seats squarely against the bore shoulder.

When installing the shaft and bearing into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Install the spacer (22) in the intermediate. Pack the

intermediate with 2/3 lb. (0.3 kg.) of No. 0 lithium

based grease (approximately 1/3 full).

Screw the bearing retaining nut (21) into the inter

mediate and check the shaft endplay. Adjust the

bearing retaining nut to establish the correct