Gorman-Rupp Pumps 04B3-F4L 1316966 and up User Manual

Page 11

OM-01216

0 SERIES

PAGE B - 4

INSTALLATION

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suc

tion inlet because the inflow will carry air down into

the sump, and air entering the suction line will re

duce pump efficiency.

If it is necessary to position inflow close to the suc

tion inlet, install a baffle between the inflow and the

suction inlet at a distance 1‐1/2 times the diameter

of the suction pipe. The baffle will allow entrained

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

the flow paths may interact, reducing the efficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a dis

tance equal to at least 3 times the diameter of the

suction pipe.

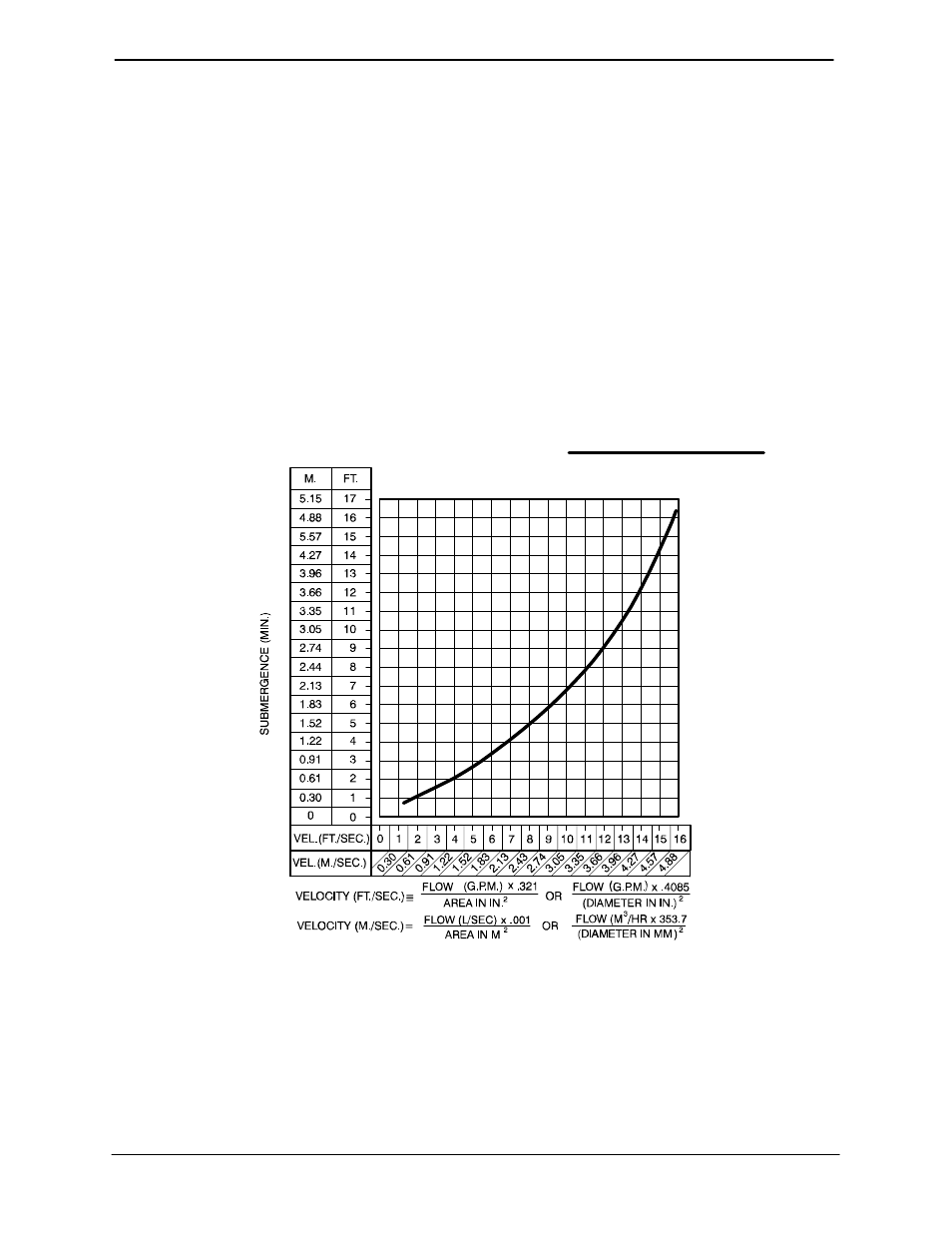

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation.

Figure 2

shows

recommended minimum submergence vs. veloc

ity.

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

FLOAT SWITCHES

Installation

The standard pump is not furnished with a means

to automatically regulate liquid level. However, if

the unit is equipped with the optional auto‐start

control system, the pump can be conformed to

start and stop as the liquid level in the wet well or

sump rises and falls. The autostart option employs

either a single or double float switch system, where

a bulb raises or lowers (floats) with the liquid level,

thus activating an enclosed miniature switch. The

floats are equipped with a socket type connector

that plugs into a matching receptacle on the auto‐

start control box.