Gorman-Rupp Pumps 06B20-B 806819 and up User Manual

Page 28

OM-01221

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

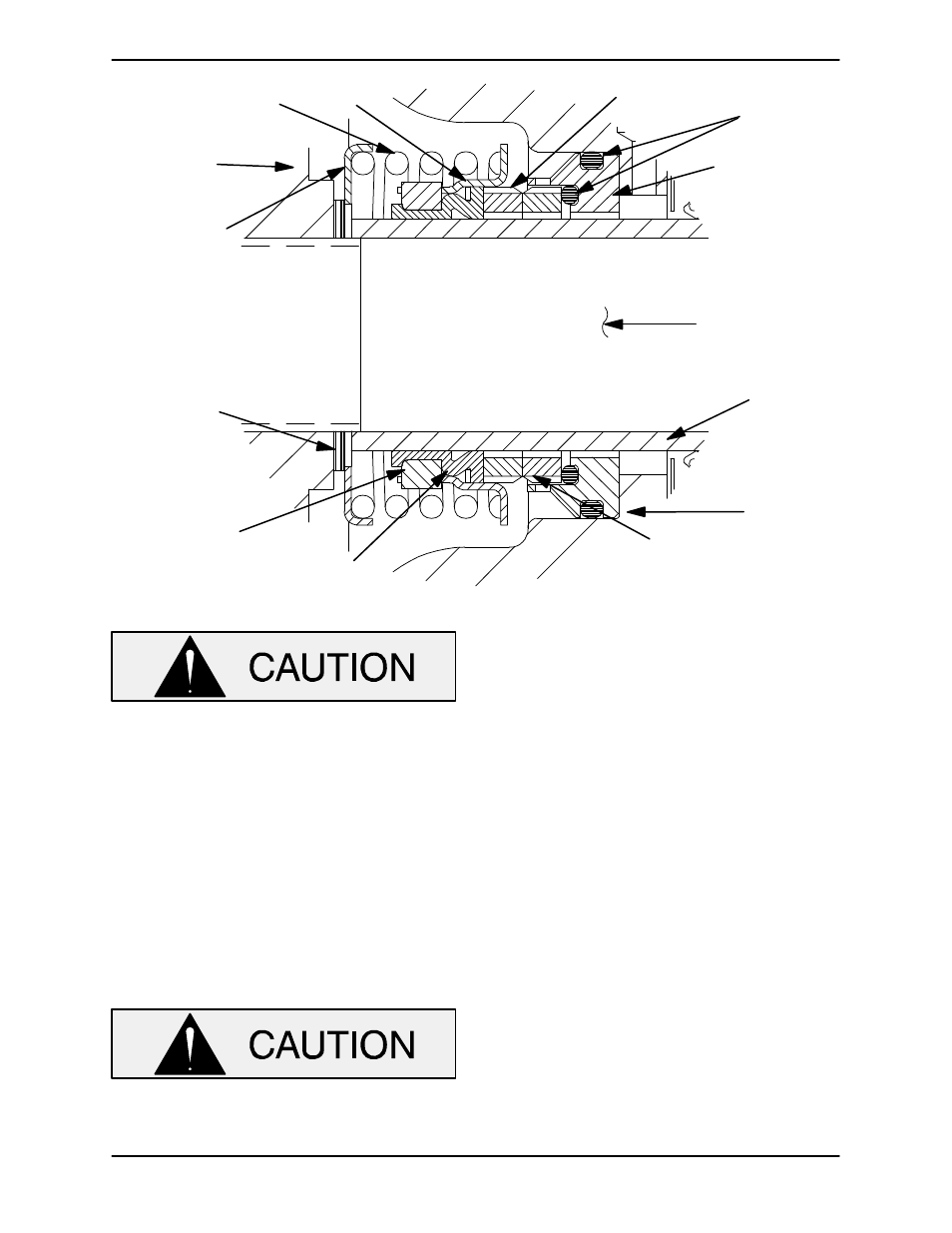

IMPELLER

SHAFT

SEAL

PLATE

ROTATING

ELEMENT

RETAINER

SPRING

IMPELLER

ADJUSTING

SHIMS

IMPELLER

BELLOWS

SHAFT

SLEEVE

O‐RING

STATIONARY

SEAT

SPRING

CENTERING

WASHER

STATIONARY

ELEMENT

DRIVE

BAND

Figure 4. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lay the seal plate on a flat surface with the impeller

side facing down. Press the oil seal (38) into the

seal plate with the lip positioned as shown in Figure

1.

Reposition the seal plate with the impeller side fac

ing up. If the wear ring (43) was removed, press the

replacement ring into the seal plate until it seats

squarely against the bore shoulder.

The wear ring must seat squarely in the

seal plate bore or binding and/or exces

sive wear will result.

Lubricate the stationary seat O‐rings with water or

light oil, and install them in the stationary seat.

Install the stationary seal element in the stationary

seat. Press this stationary subassembly into the

front of the seal plate until it seats squarely against

the bore shoulder.

Carefully slide the assembled seal plate and sta

tionary portion of the seal over the shaft. Use cau

tion not to nick or damage the stationary seat or

element on the shaft threads. Secure the seal plate

to the pedestal with the round head machine

screws (10).

Subassemble the rotating element into the retainer

and bellows. Lubricate the I.D. of the bellows with

water and slide this subassembly over the shaft

sleeve until the seal face is just flush with the under

cut end of the sleeve.

Slide the assembled shaft sleeve and rotating por

tion of the seal and onto the shaft until the polished

faces contact. Continue to push the sleeve through

the seal until it is fully seated against the shaft

shoulder. Use caution not to roll the lip of the oil seal

(38) when installing the shaft sleeve.