Gorman-Rupp Pumps 06B20-B 806819 and up User Manual

Page 24

OM-01221

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 5

plete the cuts through the ring, and remove it from

the pump casing. Use caution not to damage the

pump casing bore when removing the wear ring.

Use caution not to damage the pump cas

ing bore when removing the wear ring.

Impeller Removal

Before attempting to remove the impeller, remove

the bottle oiler and piping (11, 12, 13 and 14) from

the seal plate (9). This will prevent the oil in the res

ervoir from escaping when the impeller is removed.

Immobilize the impeller by inserting a bar between

the impeller vanes, being careful not to damage

the vanes. Disengage the hardware (44, 45 and

46).

Install the shaft key (27). Install a lathe dog on the

drive end of the shaft (28) with the “V” notch posi

tioned over the shaft key.

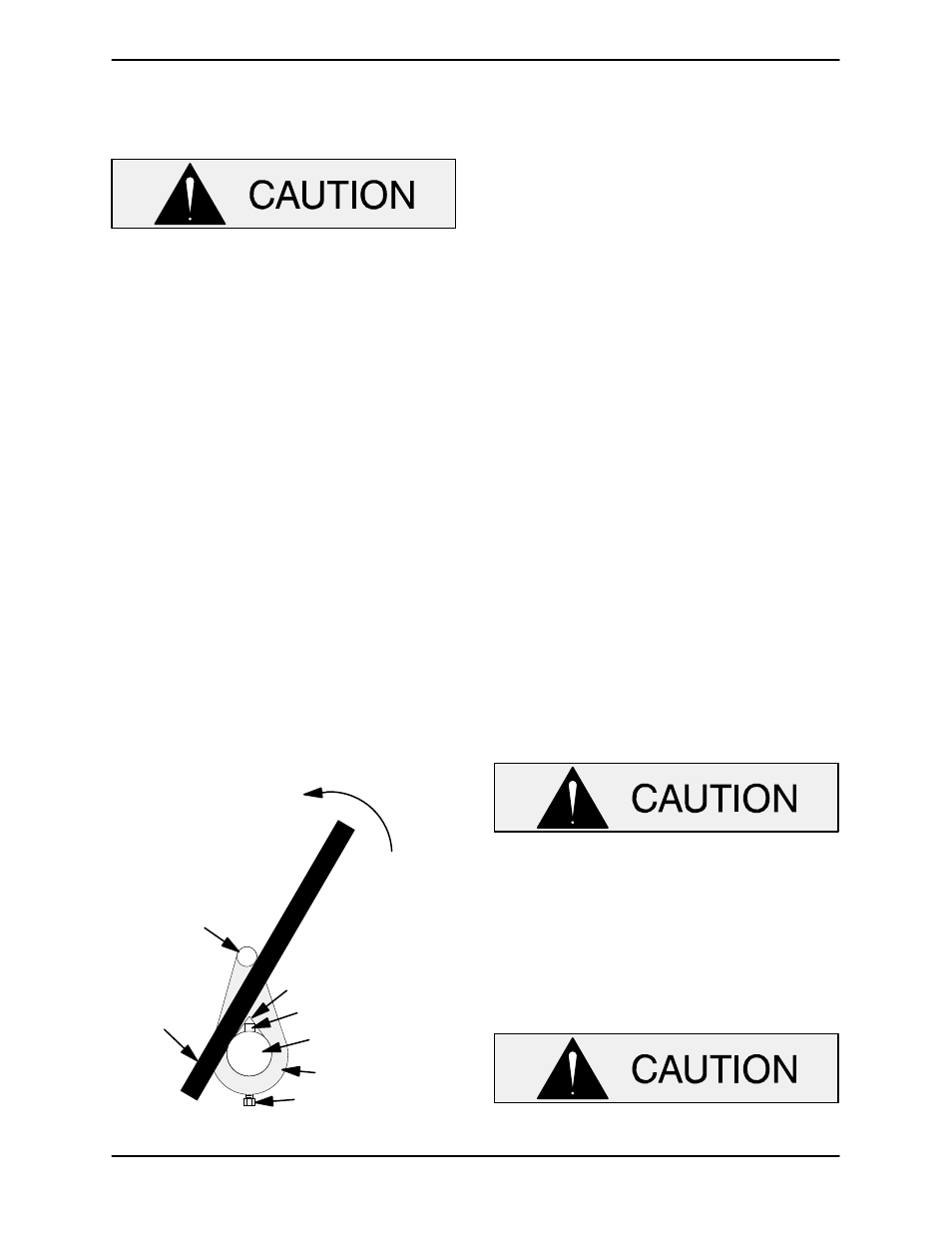

With the impeller rotation still blocked, see Figure 2

and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key

way. When the impeller breaks loose, remove the

lathe dog, key and wood block.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 2. Loosening Impeller

Unscrew the impeller from the shaft. Use caution

when removing the impeller; tension on the seal

spring will be released as the impeller is removed.

Remove the impeller adjusting shims (42). Tie and

tag the shims or measure and record their thick

ness for ease of reassembly.

Seal Removal and Disassembly

(Figures 1 and 4)

Remove the seal spring. Slide the shaft sleeve (39)

and rotating portion of the seal off the shaft as a

unit.

Apply oil to the sleeve and work it up under the rub

ber bellows. Slide the rotating portion of the seal off

the shaft sleeve.

Remove the round head machine screws (10) and

slide the seal plate and stationary seat off the im

peller shaft as a unit. Press the stationary portion of

the seal out of the seal plate from the back side. Pry

or press the oil seal (38) from the seal plate.

Inspect the wear ring (43) for excessive wear or

damage. The wear ring is secured in the seal plate

by a press fit. If replacement is required, use a

small bit to drill three holes through the ring hori

zontally, 120

_ apart. Use a saw or chisel to com

plete the cuts through the ring, and remove it from

the seal plate. Use caution not to damage the seal

plate bore when removing the wear ring.

Use caution not to damage the seal plate

bore when removing the wear ring.

Shaft And Bearing Removal And Disassembly

When the pump is properly operated and main

tained, the pedestal should not require disassem

bly. Disassemble the shaft and bearings only

when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations