Gorman-Rupp Pumps 04B52-B 1346496 and up User Manual

Page 28

OM-01232

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

Carefully slide the assembled seal plate and sta

tionary seat over the shaft. Secure the seal plate to

the pedestal with the hardware (10). Be careful not

to damage the stationary seat on the shaft keyway.

Lubricate the seal sleeve with a small amount of

light oil and slide the rotating portion of the seal

onto the sleeve until the inboard rotating element is

just flush with the undercut end of the sleeve.

Slide the sleeve and rotating portion of the seal

onto the shaft until the seal faces contact. Continue

to push the sleeve through the seal until the sleeve

seats squarely against the shaft shoulder.

Install the seal spring and spring centering washer

(59).

Impeller Installation

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the volute scroll.

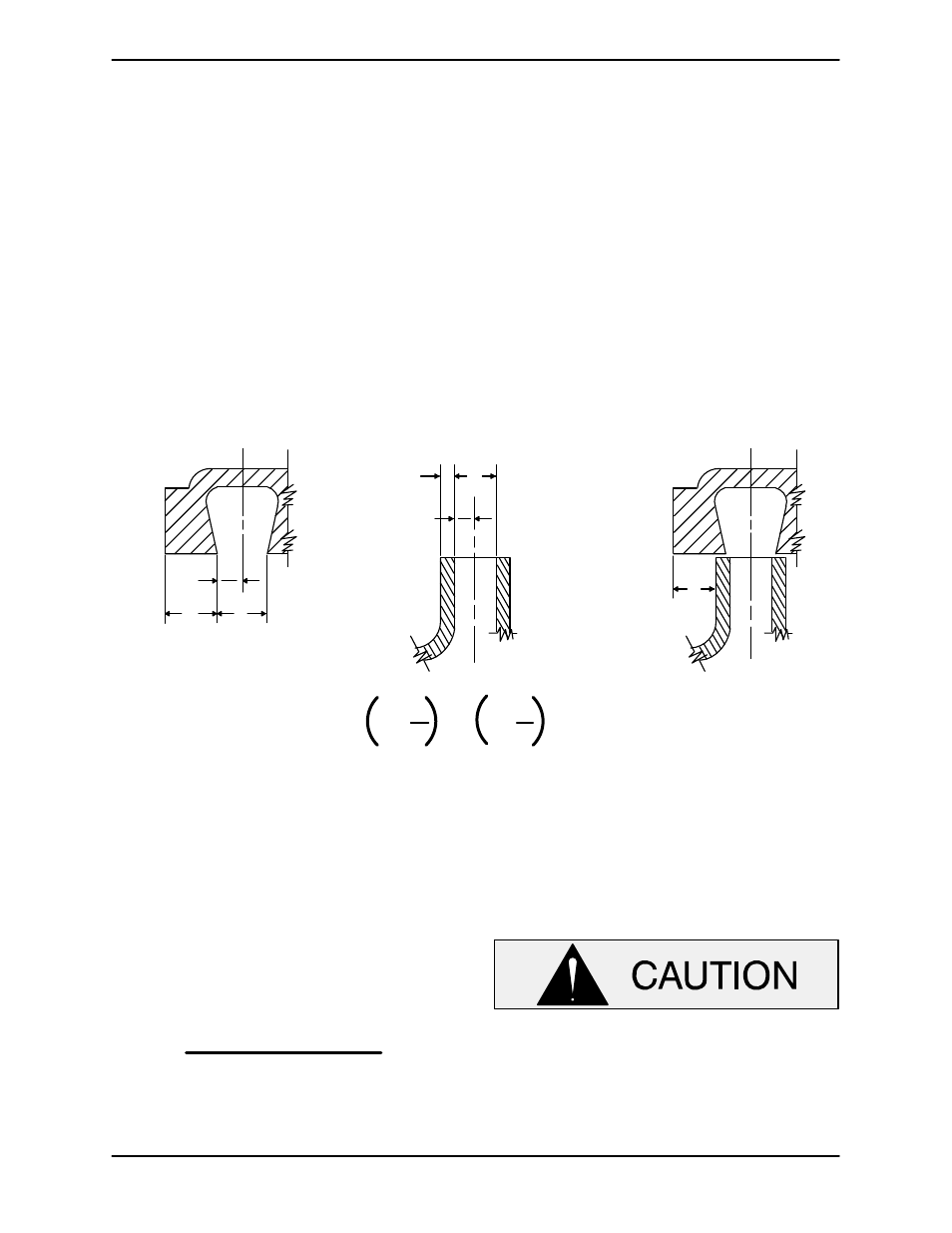

To verify the impeller positioning, measure the

pump casing and impeller as shown in Figure 4.

Use these measurements to calculate the required

impeller location (dimension E). Add or remove im

peller adjusting shims (12) until dimension E is ob

tained.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

Figure 4. Centering Impeller Within Volute Scroll

Install the correct thickness of impeller shims, and

install the impeller key (54) in the shaft keyway.

Align the impeller keyway with the key, and slide

the impeller onto the shaft until fully seated.

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping bind

ing before further reassembly.

When the impeller is properly positioned, secure it

with the hardware (41, 42 and 43).

Pump Reassembly

If removed at disassembly, press the replacement

wear ring (44) into the pump casing until it seats

squarely against the shoulder bore.

The wear ring must seat squarely in the

casing bore or binding and/or excessive

wear will result.

Install the casing gasket (9) and secure the casing

to the seal plate and pedestal with the nuts (38).

Reinstall any leveling shims under the casing