Gorman-Rupp Pumps 02D3-X1.5 3P 254341 and up User Manual

Page 24

OM-01122

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 6

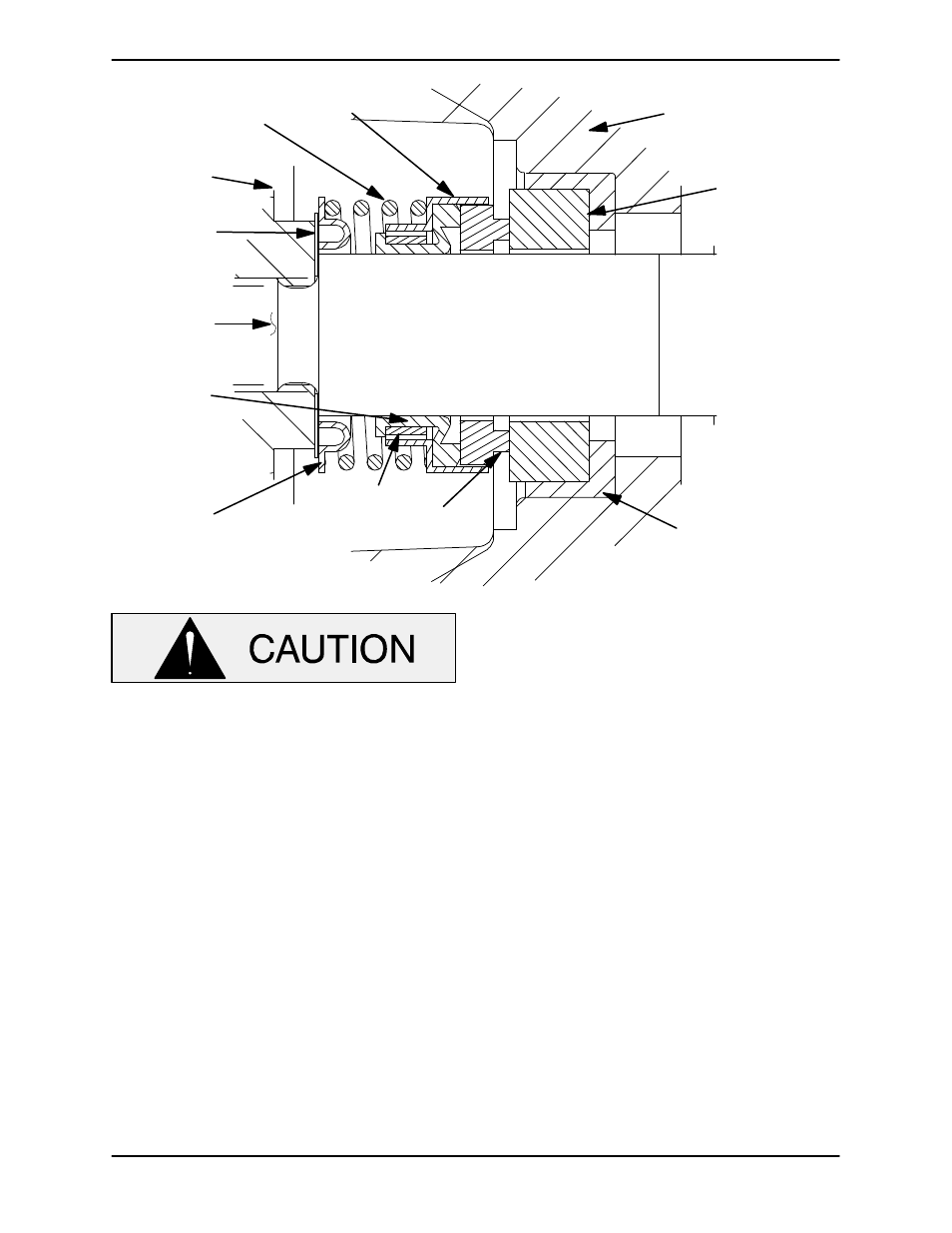

SEAL PLATE

IMPELLER

SHAFT

STATIONARY

SEAT

ROTATING

ELEMENT

DRIVE BAND

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

STATIONARY

ELEMENT

SPRING

RETAINER

Figure 2. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lay the intermediate (9) on a flat surface with the

impeller side facing up. Subassemble the station

ary element into the stationary seat and use even

pressure to press this subassembly into the inter

mediate until it seats squarely against the shoulder

bore.

Carefully slide the assembled intermediate and

stationary portion of the seal over the motor shaft.

Secure the intermediate to the motor with the hard

ware (11 and 12).

Subassemble the rotating element into the retainer

and bellows. Lubricate the I.D. of the bellows with

water and slide this subassembly onto the shaft

until the polished faces contact. Install the seal

spring and spring retainer.

Impeller Installation

Inspect the impeller and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller should

be centered within the vane plate scroll.

To verify the impeller positioning, measure the

vane plate and impeller as shown in Figure 3. Use

these measurements to calculate the required im

peller location (dimension E). Add or remove im

peller adjusting shims (17) until dimension E is ob

tained.