Gorman-Rupp Pumps 02K11-X2 3P 684441 and up User Manual

Page 25

OM-01161

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 7

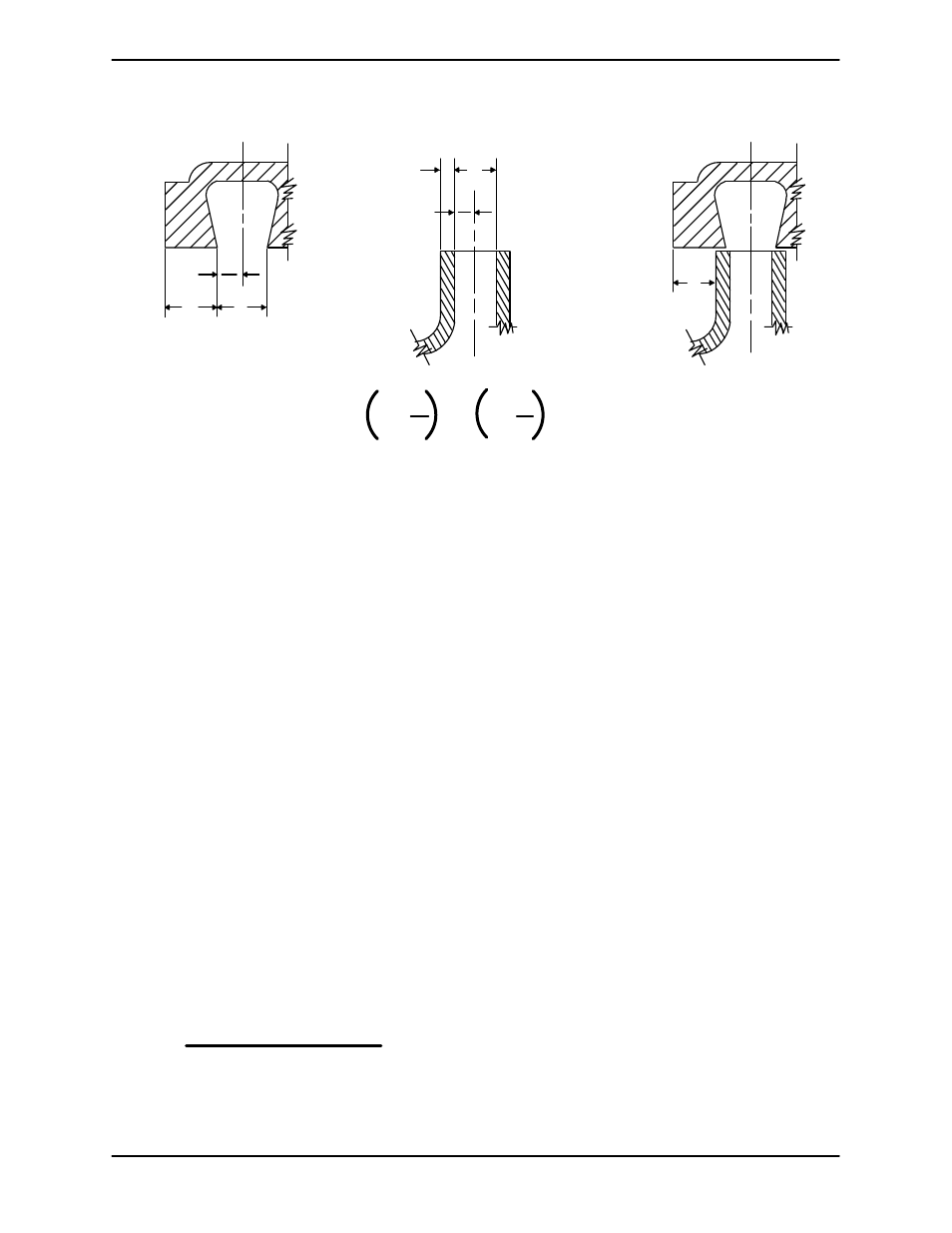

these measurements to calculate the required im

peller location (dimension E). Add or remove im

peller adjusting shims (21) until dimension E is ob

tained.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

Figure 3. Centering Impeller Within Vane Plate Scroll

Install the correct thickness of impeller shims (21)

and screw the impeller onto the shaft until fully

seated.

Apply “Loctite Threadlocker No. 242” or equivalent

compound to the impeller shaft threads. Immobi

lize the motor shaft by inserting a large flat head

screwdriver into the slot in the end of the shaft in

the front end of the motor. Secure the impeller with

the impeller jam nut (25). Torque the nut to 15 ft.

lbs. (180 in lbs. or 2,07 m. kg.).

Clean all of the old adhesive from the vane plate

and its mating surface on the intermediate. Apply a

thin film of “3M Gasket Adhesive No. 847” or equiv

alent compound to the vane plate and secure the

vane plate to the intermediate bracket using the

machine screws (5 and 6).

NOTE

After the vane plate has been installed, check for

free shaft rotation. Correct any scraping binding

before further reassembly.

Pump Reassembly

Install the vane plate O‐ring (28) onto the vane

plate shoulder. Install the casing gasket (7). Ease

the pump casing over the vane plate. Be careful

not to damage the O‐ring. Secure the casing to the

intermediate bracket with the nuts (9).

Final Pump Assembly

Install the suction and discharge lines and open all

valves. Make certain that all piping connections are

tight, properly supported and secure.

Fill the pump casing with clean liquid. Reinstall the

fill plug (4) and tighten it.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

The seal assembly is lubricated by the medium be

ing pumped and no additional lubrication is re

quired.