Gorman-Rupp Pumps 02K11-B 740364 and up User Manual

Page 24

OM-01157

0 SERIES

MAINTENANCE & REPAIR

PAGE E - 5

Impeller Removal

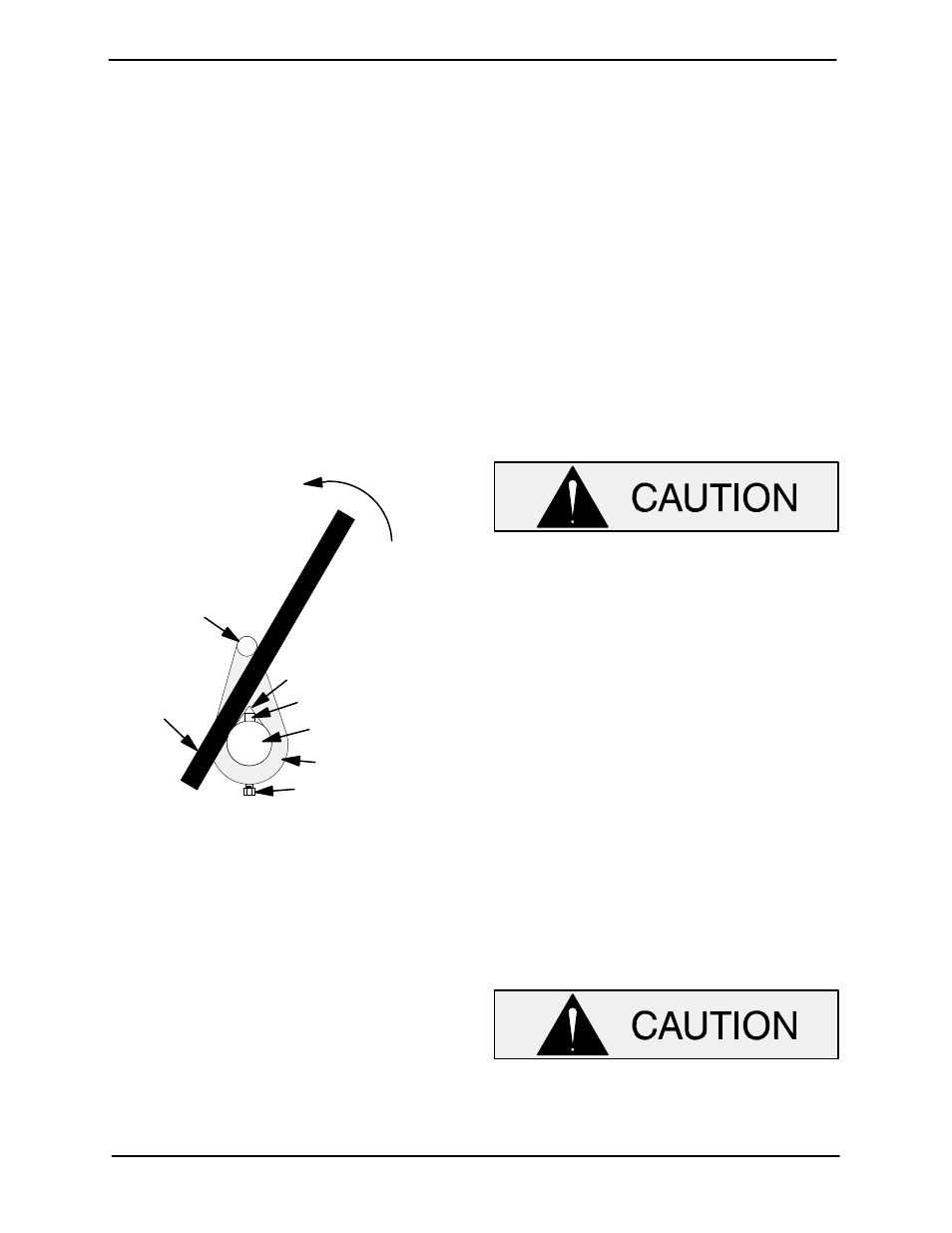

Immobilize the impeller by wedging a block of

wood or a brass rod between the vanes. Remove

the impeller jam nut (31).

Install the shaft key (18). Install a lathe dog on the

drive end of the shaft (19) with the “V” notch posi

tioned over the shaft key.

With the impeller rotation still blocked, see Figure 2

and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key

way. When the impeller breaks loose, remove the

lathe dog, key and wood block. Unscrew the im

peller in a counterclockwise direction.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 2. Loosening Impeller

Inspect the impeller and replace it if cracked or

badly worn. Slide the impeller adjusting shims (17)

off the impeller shaft. Tie and tag the shims, or

measure and record their thickness for ease of

reassembly.

Seal Removal

(Figures 1 and 3)

With the impeller and shims removed, carefully

slide the rotating portion of the seal off the shaft

(19) as a unit.

Remove the hardware (9, 10 and 11) and slide the

intermediate (22) and stationary portion of the seal

off the shaft as a unit. Disengage the hardware (12

and 13) and separate the seal cap (24) and station

ary portion of the seal from the intermediate. Re

move the stationary seat and gaskets from the seal

cap.

If no further disassembly is required, see Seal

Reassembly and Installation.

Shaft And Bearing Removal And Disassembly

When the pump is properly operated and main

tained, the bearing housing should not require dis

assembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

Remove the slinger ring (23) from the shaft. Re

move the bearing housing mounting hardware

from the base. Tie and tag any shims used under

the mounting feet for leveling.

Use snap ring pliers to remove the bearing retain

ing ring (20) from the bearing housing bore. Re

move the bearing shim set (21); tie and tag the

shims, or measure and record their thickness for

ease of reassembly.

Place a block of wood against the impeller end of

the shaft, and tap the shaft and assembled bear

ings (14 and 16) out of the bearing housing.

After removing the shaft and bearings, clean and

inspect the bearings in place as follows.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings