Gorman-Rupp Pumps 81 1/4A52-B 1287356 and up User Manual

Page 27

80 SERIES

OM−01524

MAINTENANCE & REPAIR

PAGE E − 8

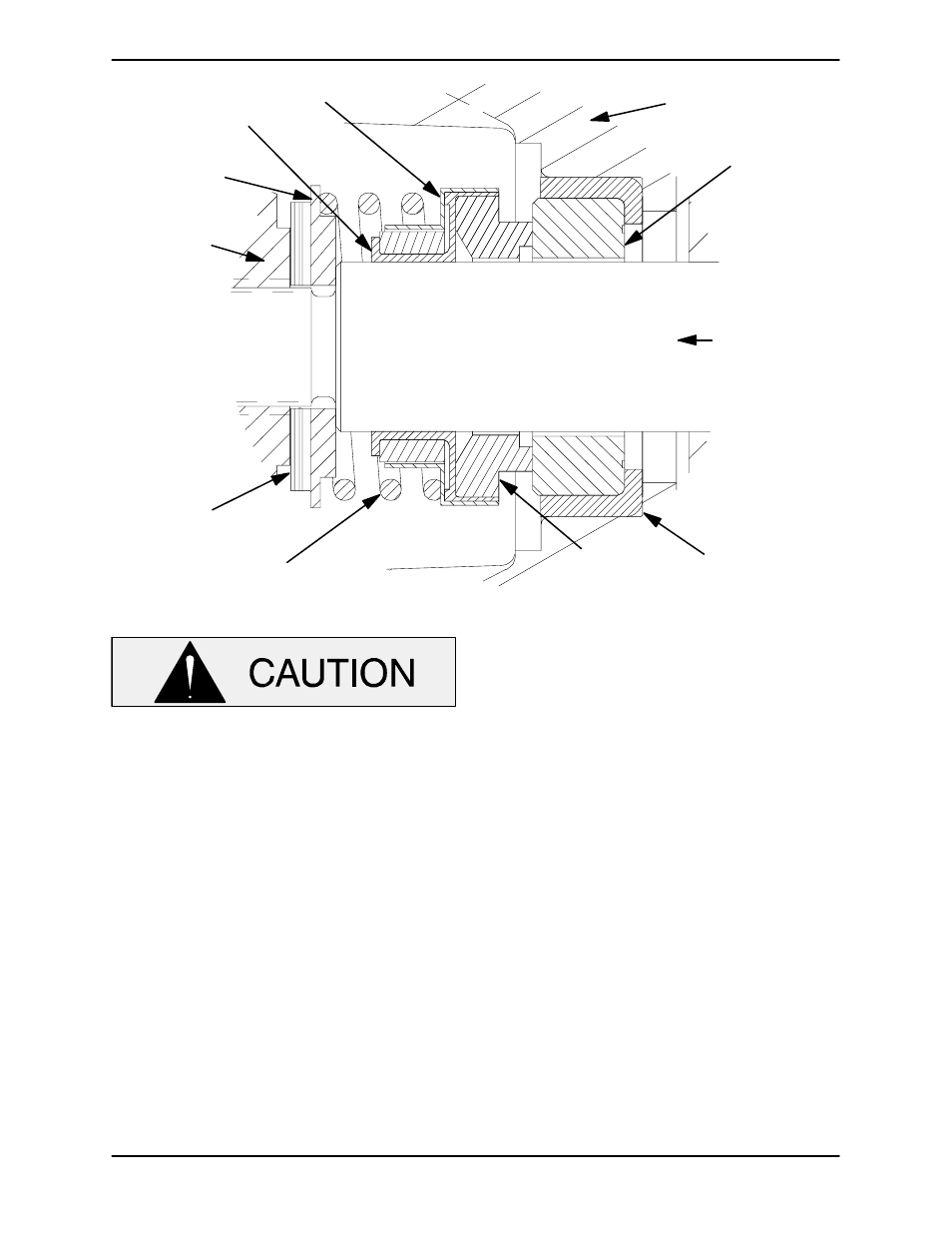

SEAL PLATE

IMPELLER

SHAFT

STATIONARY

SEAT

STATIONARY

ELEMENT

ROTATING

ELEMENT

IMPELLER

SHIMS

SPRING

RETAINER

SPRING

CENTERING

WASHER

IMPELLER

BELLOWS

Figure 2. 25285−852 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_ F (71_ C). Do

not use at higher operating temperatures.

Install the stationary element in the stationary seat.

Use your thumbs to press this subassembly into

the seal bore in the intermediate until fully and

squarely seated in the seal plate bore. After instal-

lation, wipe the stationary element sealing face

lightly in a concentric pattern with a clean, lint-free

cloth to remove any dirt or fingerprints.

Carefully slide the assembled intermediate and

stationary portion of the seal over the impeller shaft

(18) and secure the intermediate to the bearing

housing with the hardware (19, 20 and 21).

Slide the rotating portion of the seal assembly onto

the shaft until the seal faces contact.

Install the seal spring and spring centering washer

(30).

Impeller Installation

Inspect the impeller, and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (29) as previously removed. Apply ‘Loctite

Retaining Compound No. 242’ or equivalent com-

pound on the shaft threads, and screw the impeller

onto the shaft until tight.

A clearance of .002 to .006 inch ( 0,05 to 0,15 mm)

between the impeller and the vane plate (23) is

necessary for maximum pump efficiency. Position

the vane plate over the impeller, and use a feeler

gauge to measure this clearance. Add or remove

impeller shims until the proper clearance is

achieved.

Vane Plate and Pump Casing Installation

Apply ‘3-M Adhesive EC-847’ or equivalent com-

pound to the back of the vane plate, and secure the

vane plate to the intermediate with the hardware (6

and 7). Check impeller-to-vane plate clearance as

described in Impeller Installation.

Install the vane plate O-ring (24) and the pump cas-

ing gasket (22). Carefully slide the pump casing