Lubrication – Gorman-Rupp Pumps 11 1/2A2-E2 1P 1046838 and up User Manual

Page 29

10 SERIES

OM-04092

MAINTENANCE & REPAIR

PAGE E - 8

or `Never‐Seez' on the back cover shoulder, or any

surface that contacts the pump casing. This action

will reduce rust and scale build‐up.

Secure the back cover assembly by installing the

clamp bar (32) and tightening the clamp bar screw

(31). Do not over‐tighten the clamp bar screw; it

should be just tight enough to seal the back cover

shoulder.

Suction Check Valve Installation

Inspect the check valve components and replace

as required. Subassemble the check valve weights

(37 and 40) and check valve (36) using the attach

ing hardware (38 and 39).

Position the check valve assembly (35) in the suc

tion port with the large weight toward the inside of

the pump casing. Install the suction flange (4), and

secure with the nuts (42). Check the operation of

the check valve to ensure proper seating and free

movement.

Final Pump Assembly

Be sure the pump and motor are securely

mounted to the base.

Install the suction and discharge lines and open all

valves. Make certain that all piping connections are

tight, properly supported and secure.

Be sure the pump and motor have been properly

lubricated, see LUBRICATION.

Remove the fill plug assembly (6) and fill the pump

casing with clean liquid. Reinstall the fill plug and

tighten it.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

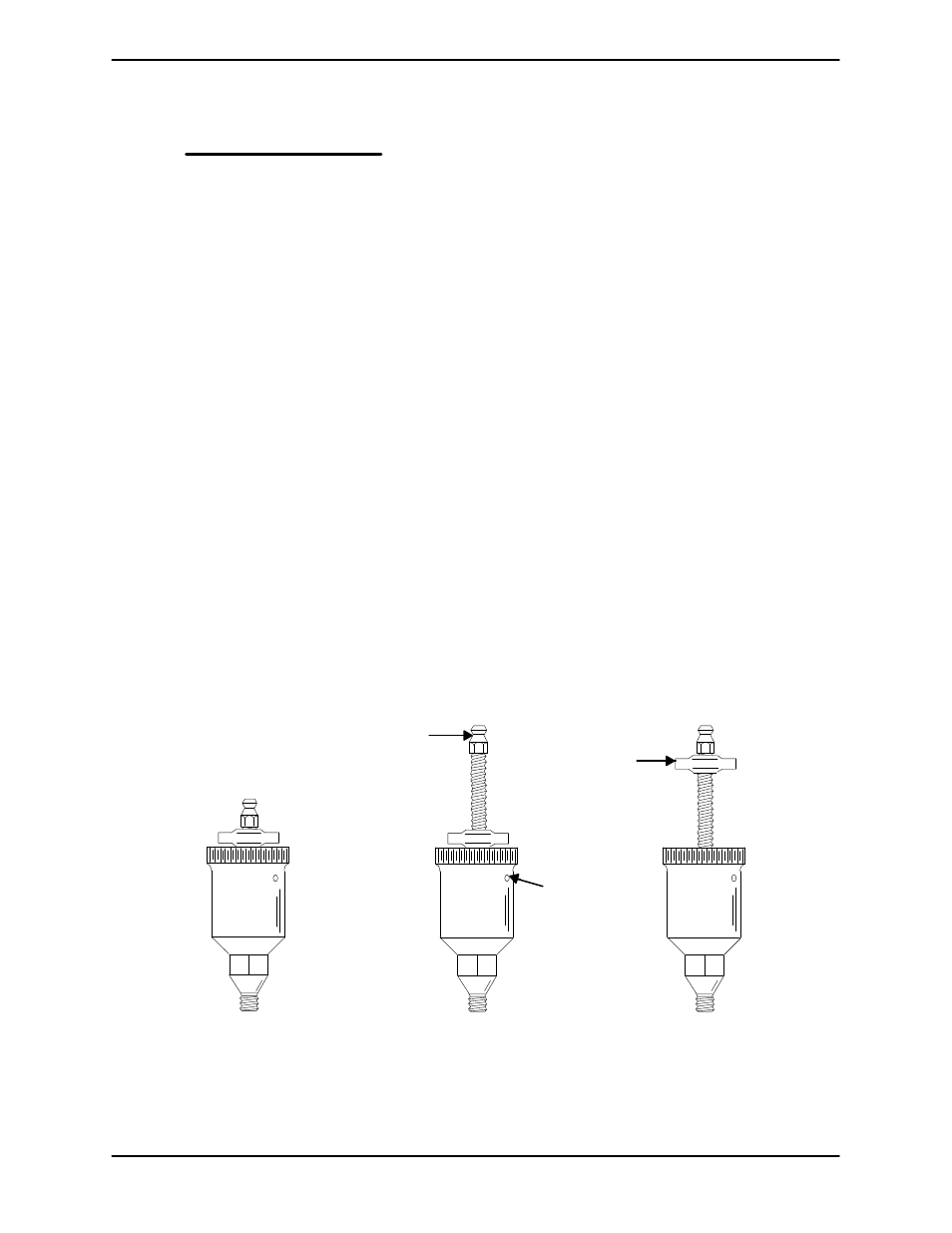

Fill the grease cup (14) through the grease fitting

with No. 2 lithium base grease until grease es

capes from the relief hole. Turn the grease cup arm

counterclockwise until it is at the top of the stem;

this will release the spring to apply grease to the

seal (see Figure 3).

GREASE

FITTING

CROSS

ARM

POSITION

WHEN

EMPTY

POSITION

FOR

FILLING

POSITION

WHEN

IN USE

RELIEF

HOLE

Figure 3. Automatic Lubricating Grease Cup

Motor

Consult the literature supplied with the motor, or

contact your local motor representative.