Gorman-Rupp Pumps 13C2-B 715157 and up User Manual

Page 14

10 SERIES

OM-00638

PAGE B - 7

INSTALLATION

Adjusting the alignment in one direction

may alter the alignment in another direc

tion. check each procedure after altering

alignment.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Most couplings require a specific gap or clearance

between the driving and the driven shafts. Refer to

the coupling manufacturer's service literature.

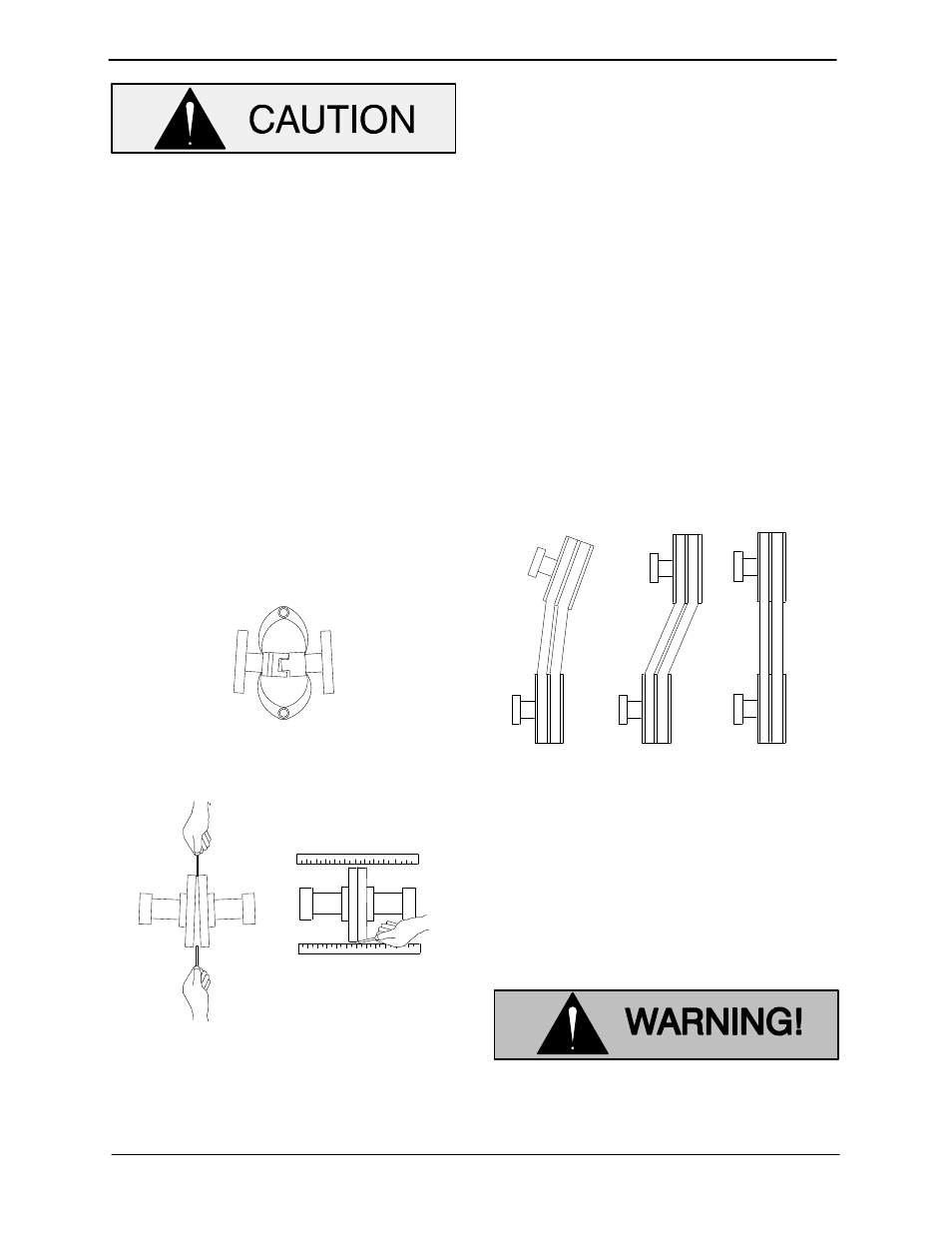

Align spider insert type couplings by using calipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90 de

grees. The coupling is in alignment when the hub

ends are the same distance apart at all points (see

Figure 4A).

Figure 4A. Aligning Spider Type Couplings

Figure 4B. Aligning Non‐Spider Type

Couplings

Align non‐spider type couplings by using a feeler

gauge or taper gauge between the coupling halves

every 90 degrees. The coupling is in alignment

when the hubs are the same distance apart at all

points (see Figure 4B).

Check parallel adjustment by laying a straightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the coupling is in horizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

straightedge to measure the amount of misalign

ment.

V‐Belt Drives

When using V‐belt drives, the power source and

the pump must be parallel. Use a straightedge

along the sides of the pulleys to ensure that the pul

leys are properly aligned (see Figure 4C). In drive

systems using two or more belts, make certain that

the belts are a matched set; unmatched sets will

cause accelerated belt wear.

MISALIGNED:

SHAFTS

NOT PARALLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHEAVES IN LINE

Figure 4C. Alignment of V‐Belt Driven Pumps

Tighten the belts in accordance with the belt manu

facturer's instructions. If the belts are too loose,

they will slip; if the belts are too tight, there will be

excessive power loss and possible bearing failure.

Select pulleys that will match the proper speed ra

tio; overspeeding the pump may damage both

pump and power source.

Do not operate the pump without the

shields and/or guards in place over the

drive shaft, belts, and/or couplings, or

other rotating parts. Exposed rotating