Gorman-Rupp Pumps 16C20-F5L 1338868 and up User Manual

Page 34

OM−02616

10 SERIES

MAINTENANCE & REPAIR

PAGE E − 13

during reassembly. This could result in premature

failure. If necessary to reuse an old seal in an emer-

gency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non-oil based solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak-

age. Clean and polish the shaft sleeve, or replace it

if there are nicks or cuts on either end. If any com-

ponents are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the O-

rings, sleeve, and bellows with water or a very

small amount of oil, and apply a drop of light lubri-

cating oil on the finished faces. Assemble the seal

as follows, (see Figure 5).

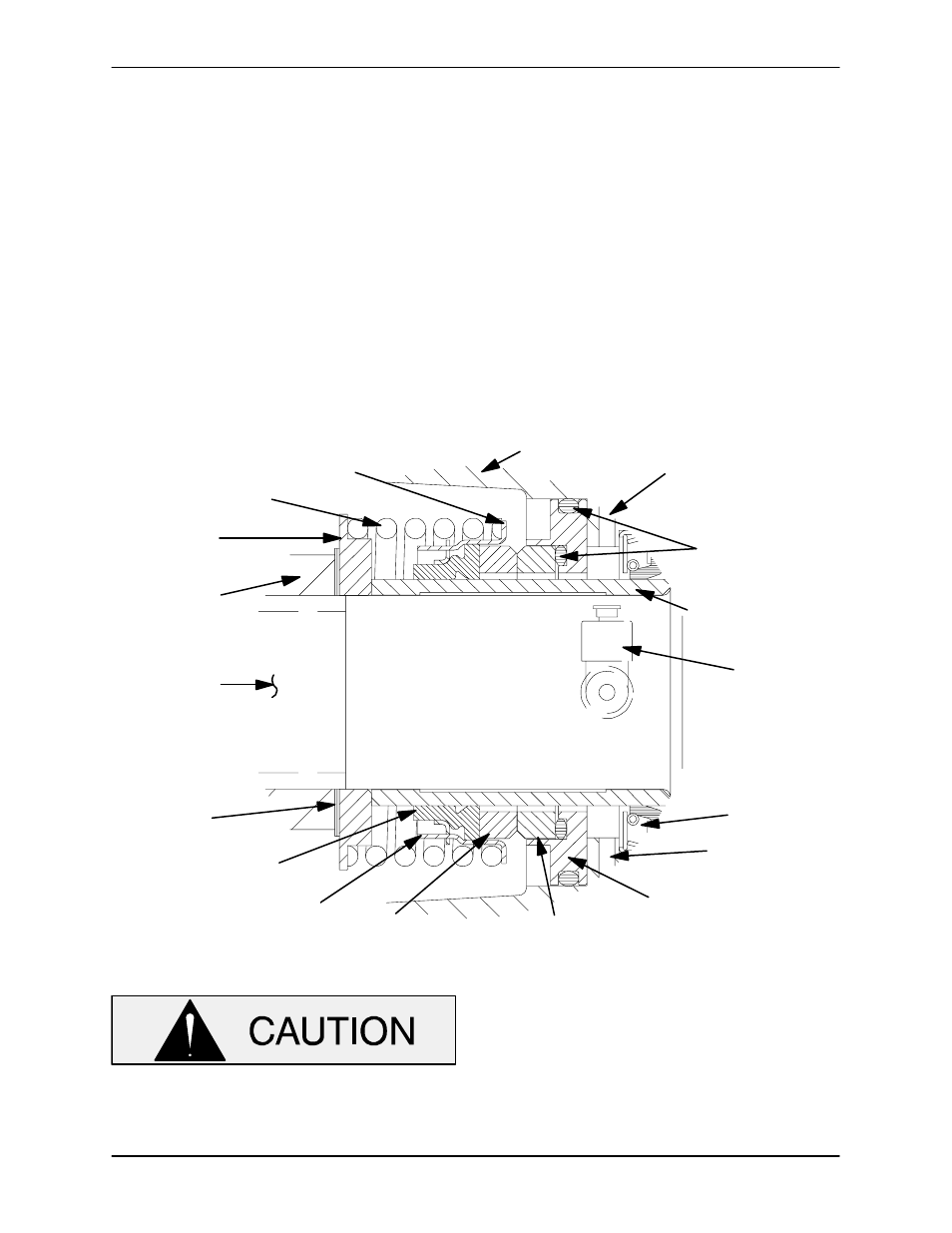

SEAL PLATE

O-RINGS

IMPELLER

OIL SEAL

STATIONARY SEAT

STATIONARY ELEMENT

ROTATING ELEMENT

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

SHAFT

SHAFT SLEEVE

DRIVE BAND

BOTTLE

OILER

AIR VENT

SPRING

HOLDER

DRAIN PLUG

Figure 5. 12461 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Install the oil seal (22) in the seal plate (54) with the

lip positioned as shown in Figure 2. Make sure the

oil seal is fully seated.

Position the seal plate against the intermediate. Be

careful not to damage the oil seal lip on the shaft

threads. Align the bottle oiler hole with the opening

in the intermediate, and temporarily secure the