Gorman-Rupp Pumps 13D1-L70EE 1258889 and up User Manual

Page 25

10 SERIES

OM-05462

MAINTENANCE & REPAIR

PAGE E - 8

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

Replacement seals are shipped with a

spring centering washer. The washer sup

plied with a new seal will not work for this

application. Discard the spring centering

washer supplied with the seal and use the

washer supplied with the pump (item 5,

Figure 1) or replace it with a new one.

To ease installation of the seal, lubricate the O‐

rings, sleeve and bellows with water or a very small

amount of oil, and apply a drop of light lubricating

oil on the finished faces. Assemble the seal as fol

lows (see Figure 3).

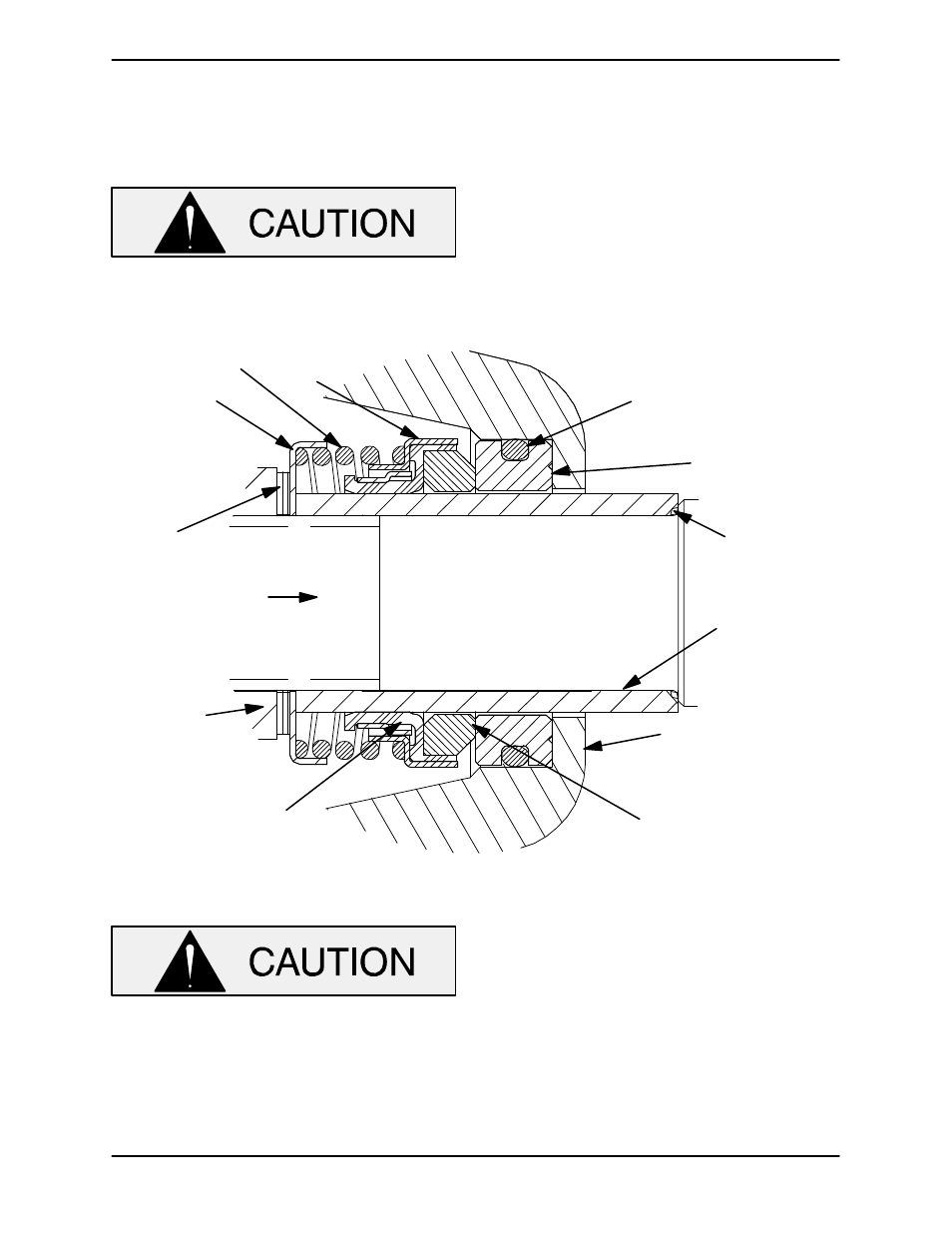

SPRING

CENTERING

WASHER

SPRING

RETAINER

O‐RING

STATIONARY

SEAT

SHAFT

SLEEVE

INTERMEDIATE

ROTATING

ELEMENT

BELLOWS

IMPELLER

ENGINE STUB

SHAFT

IMPELLER

SHIMS

SHAFT

SLEEVE

O‐RING

Figure 3. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Inspect the engine stub shaft for damage. Small

scratches or nicks may be removed with a fine file

or emery cloth. If the stub shaft is bent of excessive

ly worn, replace the shaft (see the engine service

manual).

To prevent damaging the shaft sleeve O‐ring (40)

on the shaft threads, cover the threads with electri

cal or duct tape. Slide the O‐ring over the shaft until

it seats against the shaft shoulder. Remove the

tape covering the threads. Check to ensure that

the shaft threads are free of any tape residue and

clean as required before proceeding with seal

installation.