Gorman-Rupp Pumps 84A2-4024H 1488564 and up User Manual

Page 28

OM−06412

80 SERIES

MAINTENANCE & REPAIR

PAGE E − 9

two allen head setscrews from the bushing (2).

Screw one of the setscrews into the puller hole on

the circumference of the bushing. As the coupling

and bushing separate, remove the bushing, and

slide the coupling off the shaft. Remove the shaft

key (26, Figure 3).

It is not necessary to remove the outer ring of the

coupling from the engine flywheel unless the cou-

pling must be replaced. To remove the ring, disen-

gage the hardware (4 and 5) securing it to the fly-

wheel.

Loosening Impeller

(Figure 3)

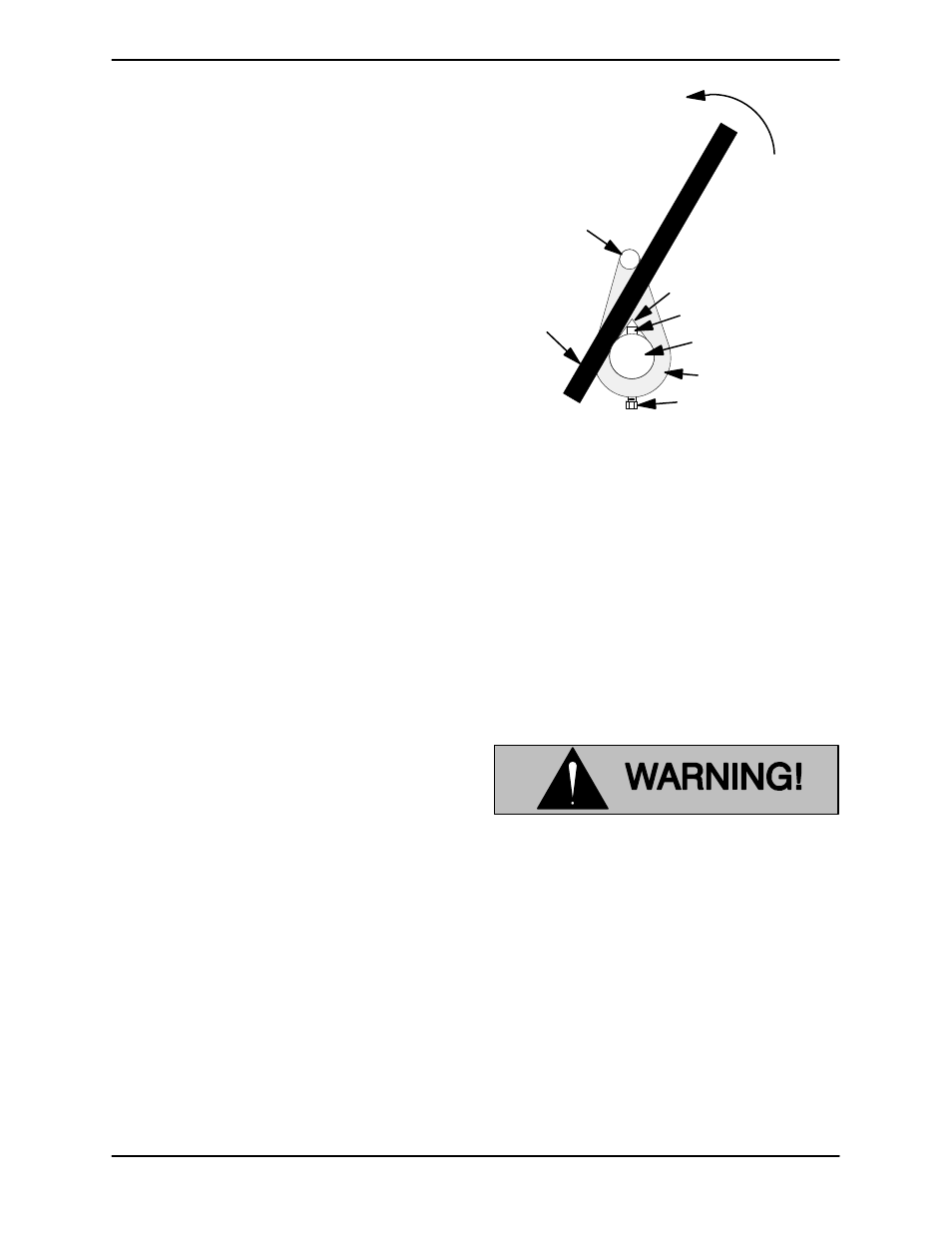

Before loosening the impeller, turn the cross arm

on the automatic lubricating grease cup (16) clock-

wise until it rests against the cover (see Figure 7 in

LUBRICATION). This will prevent the grease in the

cup from escaping when the impeller is removed.

With the pump end separated from the engine and

the suction check valve removed, reach through

the suction port and wedge a block of wood be-

tween the vanes of the impeller and the pump cas-

ing to prevent rotation.

If removed, install the shaft key (26) in the shaft

keyway. Install a lathe dog on the drive end of the

shaft (27) with the V" notch positioned over the

shaft key.

With the impeller rotation still blocked, see Figure 5

and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock-

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key-

way. When the impeller breaks loose, remove the

lathe dog, key and wood block.

Turn

Counterclockwise

Lathe Dog Arm

V" Notch

Shaft Key

Impeller

Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 5. Loosening Impeller

Pump Casing and Wear Plate Removal

(Figure 3)

To service the impeller (2), seal assembly (3), or

seal plate (36), the pump casing must be sepa-

rated from the intermediate.

Install a standard 5/8−11 UNC lifting eye in the

tapped hole in the top of the pump casing. Be sure

to screw the eye into the casing until fully engaged.

Remove the nuts (35) and use a hoist and sling of

suitable capacity to separate the pump casing and

gasket set (37) from the seal plate (36) and inter-

mediate (19).

Do not attempt to lift the complete pump

unit using the lifting eye. It is designed

to facilitate removal or installation of in-

dividual components only. Additional

weight may result in damage to the

pump or failure of the eye bolt.

Inspect the wear plate (38) and replace if scored or

worn. To remove the wear plate, disengage the

hardware (39 and 40) from the wear plate studs,

and pull the wear plate from the pump casing.

Impeller Removal

(Figure 3)

With the impeller loosened as previously de-

scribed in Loosening Impeller, unscrew the im-