Gorman-Rupp Pumps 84A2-4024H 1488564 and up User Manual

Page 11

OM−06412

80 SERIES

PAGE B − 4

INSTALLATION

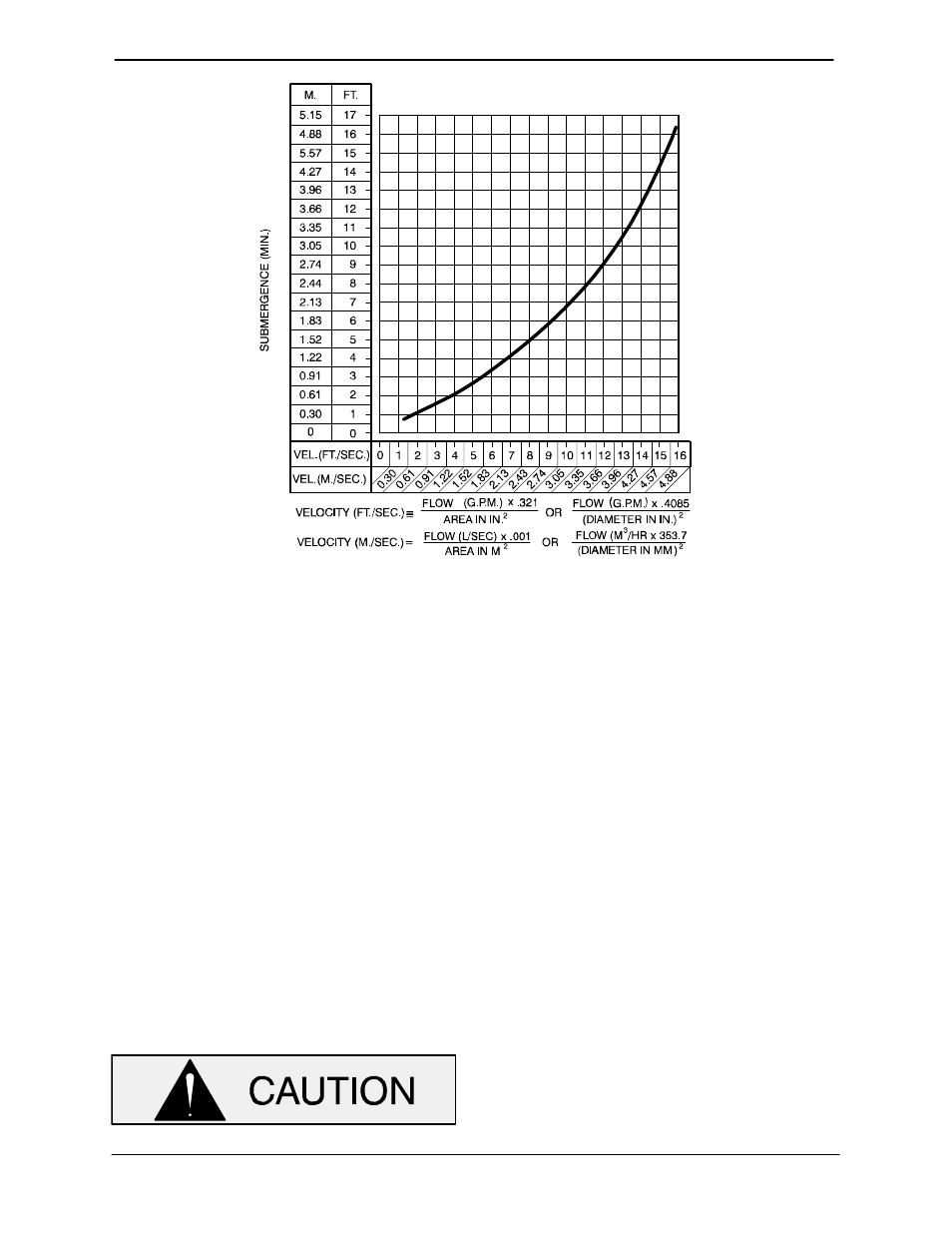

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a si-

phon breaker is used in the line. Otherwise, a si-

phoning action causing damage to the pump

could result.

Valves

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be in-

stalled in the discharge line to protect the pump

from excessive shock pressure and reverse rota-

tion when it is stopped.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

Bypass Lines

If a system check valve is used due to high dis-

charge head, it may be necessary to vent trapped

air from the top of the pump during the priming

process. This may be accomplished by installing a

bypass line from the top of the pump, back to the

source of liquid. The end of the bypass line must be

submerged. The line must be large enough to pre-

vent clogging, but not so large as to affect pump

discharge capacity.

ALIGNMENT

The alignment of the pump and engine is critical for

trouble-free mechanical operation. The driver and

pump must be mounted so that their shafts are

aligned with and parallel to each other. Refer to Se-

curing Intermediate And Drive Assembly To En-

gine in MAINTENANCE AND REPAIR, Section E

for details.