Gorman-Rupp Pumps 86A2-F4L 1322538 and up User Manual

Page 19

OM-00957

80 SERIES

TROUBLESHOOTING

PAGE D - 2

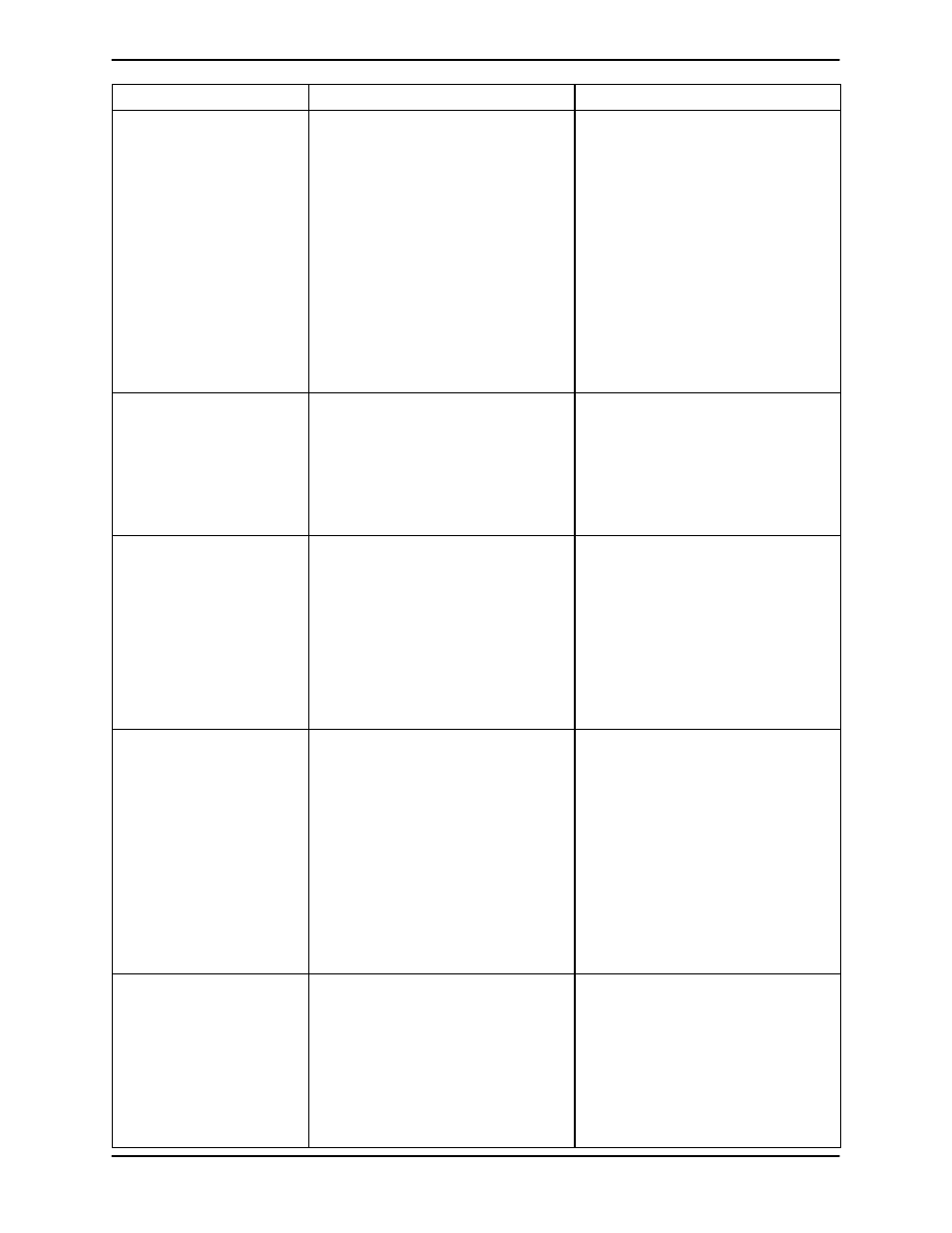

TROUBLE

POSSIBLE CAUSE

PROBABLE REMEDY

PUMP STOPS OR FAILS

TO DELIVER RATED

FLOW OR PRESSURE

(cont.)

Suction intake not submerged at

proper level or sump too small.

Impeller or other wearing parts worn

or damaged.

Impeller clogged.

Discharge head too high.

Suction lift too high.

Pump speed too slow.

Check installation and correct sub

mergence as needed.

Replace worn or damaged parts.

Check that impeller is properly cen

tered and rotates freely.

Free impeller of debris.

Install bypass line.

Measure lift w/vacuum gauge. Re

duce lift and/or friction losses in suc

tion line.

Check engine output; consult engine

operation manual.

PUMP REQUIRES TOO

MUCH POWER

Pump speed too high.

Discharge head too low.

Liquid solution too thick.

Bearing(s) frozen.

Check engine output.

Adjust discharge valve.

Dilute if possible.

Disassemble pump and check

bearing(s).

PUMP CLOGS

FREQUENTLY

Discharge flow too slow.

Liquid solution too thick.

Discharge line clogged or re

stricted; hose kinked.

Suction check valve or foot valve

clogged or binding.

Open discharge valve fully to in

crease flow rate, and run engine at

maximum governed speed.

Dilute if possible.

Check discharge lines; straighten

hose.

Clean valve.

EXCESSIVE NOISE

Cavitation in pump.

Pumping entrained air.

Pump or drive not securely

mounted.

Impeller clogged or damaged.

Reduce suction lift and/or friction

losses in suction line. Record vacu

um and pressure gauge readings

and consult local representative or

factory.

Locate and eliminate source of air

bubble.

Secure mounting hardware.

Clean out debris; replace damaged

parts.

BEARINGS RUN TOO

HOT

Bearing temperature is high, but

within limits.

Low or incorrect lubricant.

Suction and discharge lines not

properly supported.

Drive misaligned.

Check bearing temperature regular

ly to monitor any increase.

Check for proper type and level of

lubricant.

Check piping installation for proper

support.

Align drive properly.