Gorman-Rupp Pumps 06D17-GAR 708768 thru 1000782 User Manual

Page 27

OM−01274

0 SERIES

MAINTENANCE & REPAIR

PAGE E − 7

worn, replace the complete seal; never mix old

and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the sta-

tionary seat O-ring, bellows and pinion shaft with

water or a very small amount of oil, and apply a

drop of light lubricating oil on the finished faces.

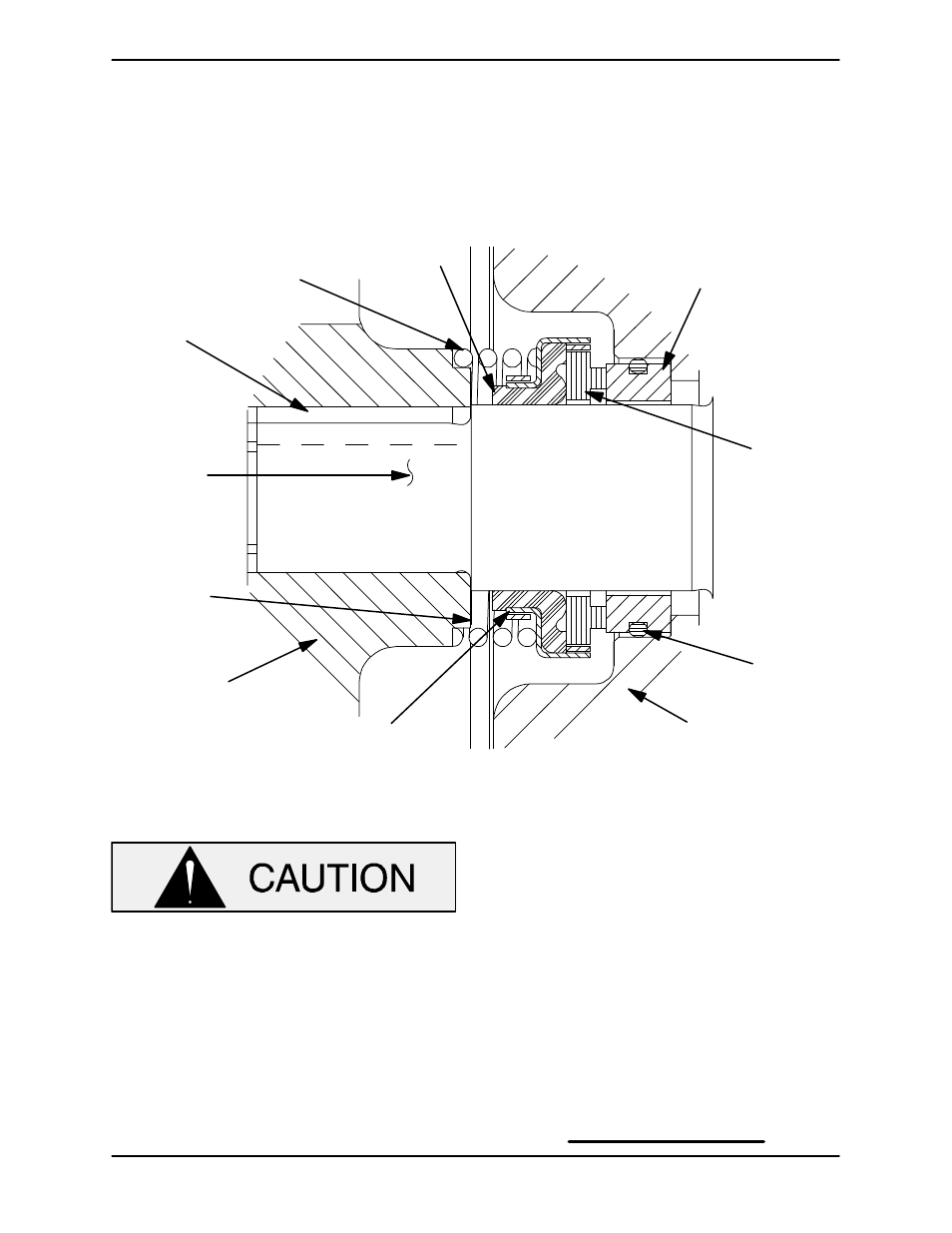

Assemble the seal as follows, (see Figure 2).

SEAL

SPRING

SHAFT

KEY

IMPELLER

SHIMS

IMPELLER

RETAINER

O-RING

STATIONARY

SEAT

IMPELLER

SHAFT

PUMP CASING

BELLOWS

ROTATING

ELEMENT

Figure 2. 25271−192 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Inspect the pinion shaft (46) for distortion, nicks,

scratches, or damage to the shaft keyway. Dress

small nicks or burrs with a fine file or emery cloth. If

excessive wear exists or the shaft is defective, refer

to GEARBOX DISASSEMBLY and replace the

shaft.

Lubricate the stationary seat O-ring with light oil

and install it in the groove in the stationary seat.

Use thumb pressure to press this subassembly

into the pump casing until fully seated. Be careful

not to damage the seal face. After installation, wipe

the seal face in a concentric pattern with a clean,

lint-free cloth to remove any fingerprints.

NOTE

It is recommended that a tapered sleeve (see Fig-

ure 3) be installed over the shaft keyway to ease in-

stallation of the rotating portion of the seal. This tool

can be made from steel tubing or black pipe.