Gorman-Rupp Pumps 82E1-L100EE-X 1518664 and up User Manual

Page 26

OM-05132

80 SERIES

MAINTENANCE & REPAIR

PAGE E - 8

age. If any components are worn, replace the com

plete seal; never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter. Discard the spring centering washer in

cluded with the seal. It is not used in this applica

tion (see Figure 3).

To ease installation of the seal, lubricate the bel

lows and O‐ring with water or a very small amount

of light lubricating oil, and apply a drop of light lu

bricating oil on the finished seal faces. Assemble

the seal as follows (see Figure 3).

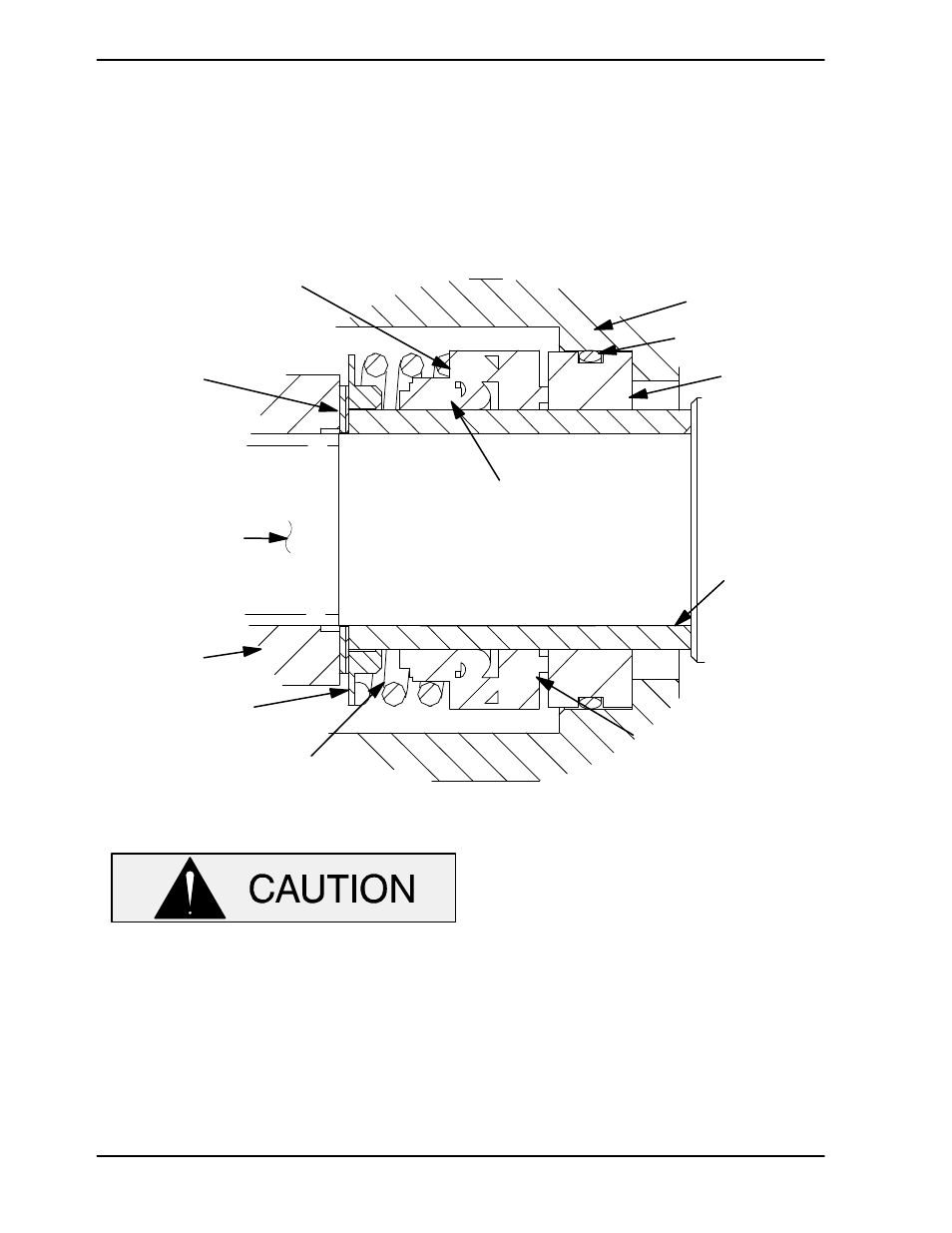

ENGINE

CRANKSHAFT

O‐RING

IMPELLER

IMPELLER

SHIMS

SHAFT

SLEEVE

STATIONARY

SEAT

ROTATING

ELEMENT

SPRING

INTERMEDIATE

SPRING

CENTERING

WASHER

BELLOWS

RETAINER

Figure 3. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C) Howev

er most petroleum products such as gaso

line are more efficiently handled at ambient

temperatures. Do not use at higher operat

ing temperatures.

If the intermediate (7) was removed, lay it on a flat

surface with the impeller side facing up.

Subassemble the O‐ring onto the stationary seat,

and press this subassembly into the intermediate

bore until it seats squarely against the shoulder.

Slide the assembled intermediate and stationary

seat over the shaft and secure the intermediate to

the engine bellhousing with the hardware (12 and

13). When installing the intermediate, use caution

not to damage the stationary seat on the shaft

threads.

NOTE

If the intermediate was not separated from the en

gine during disassembly, subassemble the O‐ring

into the stationary seat, and use a piece of plastic