Iii) gas connections, Gas pressure, Purging caution – John Wood Atmospheric Vent Light-Duty User Manual

Page 5: Iv) water pipe connections

– 5 –

III) GAS CONNECTIONS

Install the gas piping as shown in Figure 4. Use only new pipe and

fittings with clean-cut threads. Sealing compounds used on the

pipe threads shall be approved for use with natural and propane

gas.

Use gas piping of adequate sizing to ensure full gas input. Gas

piping material must be approved for use with natural gas and

propane fuels. All piping must comply with all local codes or , in the

absence of local codes, the latest edition of CAN/CGA B149.1

installation code in Canada / National Fuel Code ANSI Z223•1

(NFPA 54) in the USA. The final connection to the water heater is

made using 1/2” N.P.T.

Before connecting to the gas service, check that a properly sized

gas meter and regulator are available to service the water heater.

If other appliances are using the same meter and regulator,

ensure that the capacity of the meter and regulator matches that

of the combined input of all appliances connected to it.

• Ensure that the piping is large enough to satisfy the

requirements of all appliances connected to the gas service.

Undersize piping can restrict gas flow causing the water heater

to perform poorly. Improperly sized piping may pose a safety

hazard.

• A manual gas shut-off valve shall be installed in the gas line

near the water heater. A union is recommended for ease of

service.

• To trap dirt or foreign material in the gas supply, a dirt (drip) leg

shall be installed in the piping at the heater.

• Apply joint compound (pipe dope) to the male ends of the

threads before joining pipe sections. Use only compounds that

are compatible with natural gas and propane fuels. To prevent

damage to the gas valve, do not over-tighten.

Gas Pressure

GSW Water Heating Company recommends that the gas supply

pressure, as measured on the inlet side of the water heater

control, be set at 7.0“ water column for natural gas and 11.0“ water

column for propane gas. The above pressures must be measured

during water heater operation. The gas control supplied with this

water heater is designed for a maximum inlet pressure of 0.5 psi

(14” water column). For natural and propane gas do not exceed

0.5 psi (14” water column).

WARNING

Exposure to a higher gas supply pressure may cause damage to

the control, resulting in explosion or fire. Consult your local gas

supplier and gas authorities. DO NOT PUT INTO SERVICE IF

OVER-PRESSURIZATION HAS OCCURRED.

The minimum inlet gas pressure required is 4.5 “ water column

for natural gas and 11.0 “ water column for propane gas.

Purging Caution:

Gas line purging is required to eliminate air from the piping

system. Purging should be performed by persons experienced in

this type of gas service. Do not purge in confined areas or space

where ignition may occur. To avoid risk of fire or explosion ensure

the area is well-ventilated and all sources of ignition are de-

activated. Contact your local gas authority for local requirements.

IMPORTANT:

Disconnect the water heater from the gas piping

during any high pressure testing above 0.5 psi. Perform a leak test

at normal gas pressure on all fittings after all connections have

been made and the gas has been turned on. Soap test all

connections of the gas system - bubbles indicate leaks.

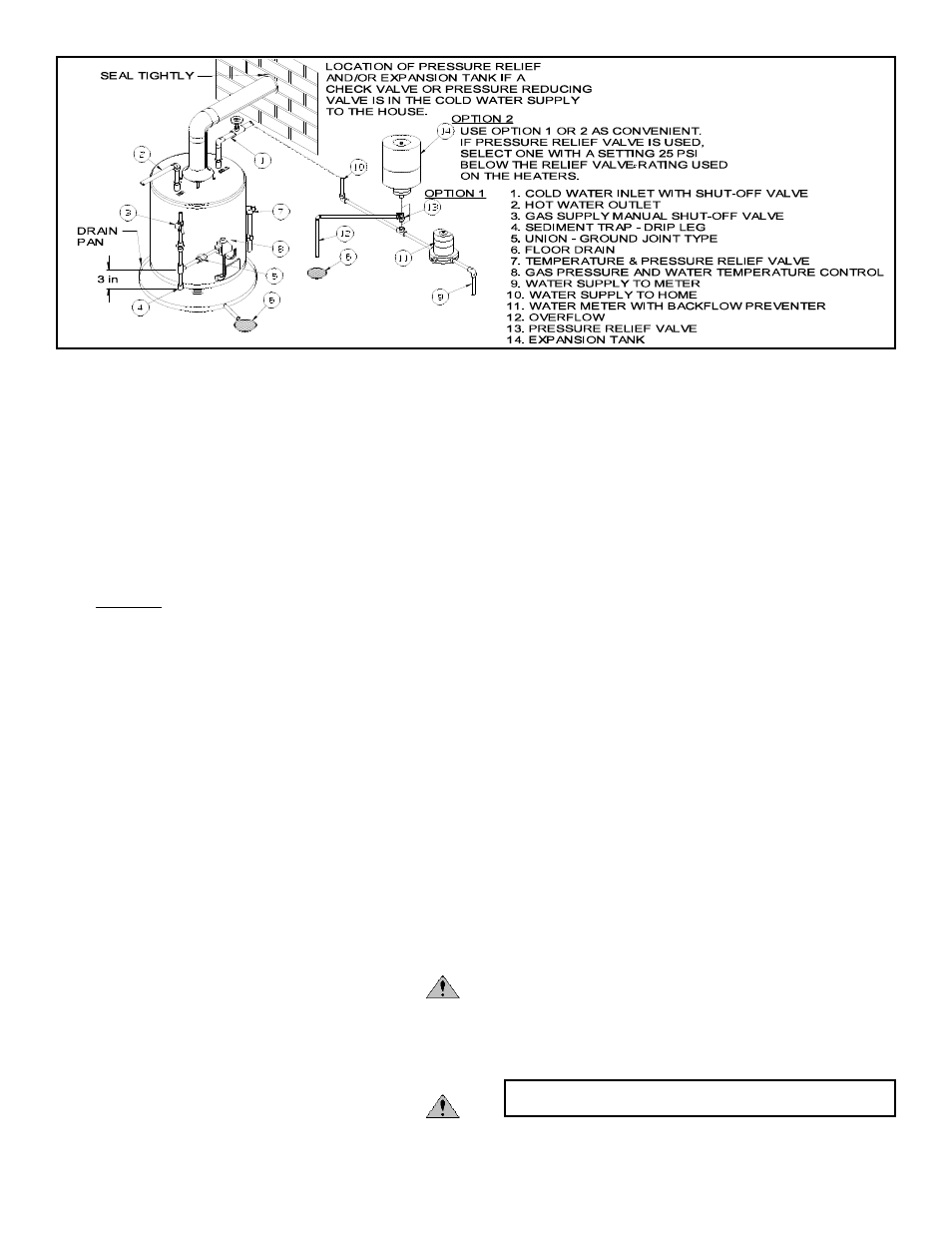

IV) WATER PIPE CONNECTIONS

Pipe and fittings should be installed in compliance with the

installation drawing. Have the installer show you where the water

shutoff valve is installed so that you know where and how to shut

the water off. It is recommended that such a valve be located in

close proximity to the cold water inlet of the water heater. Water

piping and fittings should be installed as shown in Figure 5.

NOTE: THE FITTINGS SUPPLIED WITH THIS WATER

HEATER ARE 3/4” NPT.

1. Close main water supply and drain the piping system where

water heater is to be connected.

2. Connect the cold water supply to the fitting marked ‘COLD’,

and the hot water outlet to the fitting marked ‘HOT’.

3. When attaching solder (sweat) fittings, DO NOT APPLY

HEAT DIRECTLY TO THE WATER HEATER NIPPLES

or the plastic liners will be damaged. Sweat adapters to the first

section of the water piping before threading onto the water

heater. Use a good grade of pipe joint compound that is

certified for use with potable water on the threaded fittings.

4. Install a manual shut-off valve in the cold water supply line. It is

good plumbing practice to include unions at the hot and cold

connections as shown. (Figure 5)

5. IMPORTANT: Before putting the water heater into service,

make sure that a properly rated and sized temperature and

pressure relief valve is installed in the designated fitting in the

water heater. See Temperature and Pressure Relief Valve

section below.

The relief valve is necessary to avoid excessive water pressure

or water temperature from developing. Such a condition could

cause serious personal injury due to scalding or serious

physical damage to the water heater. This safety device shall

be checked annually for proper operation.

CHECK

LOCAL CODES!

6. With water piping installed, check that a hot water faucet

served by the water heater is open and that the heater drain

valve is closed. Open the cold water supply valve and fill the

water heater and piping system with water. When an

uninterrupted stream of water flows from the faucet, the system

is full. Close faucet. Check for leaks and repair as necessary.

7. Connect a hose to the drain valve and connect to drain.

Open drain and let water run until clear to flush out any

foreign matter that may have entered the system. Once

flushed, close the drain valve and disconnect hose.

NEVER OPERATE THE HEATER IF IT IS NOT

COMPLETELY FILLED WITH WATER.

FIGURE 4